|

Cost and Performance

Report:

|

Preparation of this report has been funded wholly or in part by the U.S. Environmental Protection Agency under Contract Number 68-W3-0001. It has been subject to administrative review by EPA headquarters and Regional staff and by the technology vendor. Mention of trade names for commercial products does not constitute endorsement or recommendation for use.

This report presents cost and performance data for a thermal desorption/dehalogenation treatment application at the Wide Beach Development Superfund site (Wide Beach) in Brant, New York. Contamination of soil at the Wide Beach site resulted from the spraying of waste oil containing polychlorinated biphenyls (PCBs) over the roadways in the community to control dust. A Record of Decision (ROD), signed in 1985, required excavation, stockpiling, and treatment of soil from areas including roadways, drainage ditches, and residential yards where concentrations of PCBs were greater than 10 mg/kg. In response to the ROD and a 1988 interagency agreement between EPA and the U.S. Army Corps of Engineers (USACE), SoilTech’s mobile anaerobic thermal processor (ATP) system was used in conjunction with alkaline polyethylene glycol (APEG) dechlorination to treat contaminated soil at this site. The USACE specified that the concentration of PCBs in soil treated at Wide Beach should not exceed 2 mg/kg.

The system was operated from October 1990 to September 1991. Approximately 42,000 tons of stockpiled soil contaminated with PCBs, mainly Arochlor 1254, at concentrations ranging from 10 to 5,000 mg/kg, were treated. The Wide Beach project is notable for being the first full-scale treatment application using SoilTech’s ATP system in conjunction with APEG dechlorination to treat soil at a Superfund site contaminated with PCBs.

The SoilTech ATP system used at Wide Beach consisted of a feed system, the ATP unit (a rotary kiln thermal desorber), a vapor recovery system, a flue gas treatment system, a tailings handling system, and a module for preparing reagents used for the APEG dechlorination process. Wastewater from the vapor recovery system was treated on-site and then disposed of at an off-site treatment facility. Waste oil from the vapor recovery system containing PCBs was dechlorinated using APEG and then recycled as carrier oil in the vapor recovery system. An EPA SITE Demonstration, conducted during the full-scale operation in May of 1991, indicated that 98 percent of the PCBs that entered the ATP system were dechlorinated.

The thermal description system at Wide Beach achieved the specified soil cleanup standards. Concentration of PCBs in treated soil samples were generally at or below the reported detection limit of 0.5 mg/kg. However, treated soils could not be used as backfill, because they were not as cohesive as the excavated soil, and were disposed of off site as nonhazardous waste.

The costs for the treatment application at Wide Beach, excluding costs for construction of a concrete pad for the ATP unit and for off-site disposal of the treated soil, were $11,600,000.

Table of Contents | Forward to Site Information

Wide Beach Development Superfund Site

Brant, New York

CERCLIS #: NY0980652259

ROD Date: September 30, 1985

Type of Action: Remedial

Demonstration Test Associated with Application? Yes (see Appendix A and

Reference 4)

EPA SITE Program Test Associated with Application? Yes (see Reference

9)

Period of Operation: October 1990 to September 1991

Quantity of Soil Treated During Application: 42,000 tons

Historical Activity That Generated Contamination at the Site:

Spraying of waste oil over roadways for dust control. [7]

Corresponding SIC Codes: Not applicable

Waste Management Practices That Contributed to Contamination: Road

Oiling-Application of PCB-containing waste oils to the roadways for dust

control.

Site History: The Wide Beach Development Superfund Site (Wide Beach) is a 55 acre, lake-side community located in Brant, New York, as shown on Figure 1. From 1964 until 1978, waste oil containing polychlorinated biphenyls (PCBs) was applied to the roadways in the community to control dust. Soil from the roadways was excavated during the installation of a 1-mile sanitary sewer trench in the community during 1980. Excavated soil was used as fill in several residential yards. [7]

Figure 1. Site Location

An Erie County Department of Environment and Planning investigation of an odor complaint led to the discovery of 19 drums in a wooded area in the Wide Beach Development community. Two of the drums contained waste oil contaminated with PCBs. Further investigation revealed that PCBs were present in soil from roadways and residential yards, in vacuum cleaner dust from residential homes, and in water from residential wells. The Wide Beach Development site was placed on the National Priorities List in September 1983. [7]

A remedial investigation and feasibility study (RI/FS) was conducted from 1984 to 1985. [18] The RI/FS results indicated that:

Based on these results, EPA implemented a removal action, which was conducted from June to July 1985. The removal action included paving roadways, drainage ditches, and driveways, shampooing and vacuuming rugs, replacing air conditioner and furnace filters in residential homes, and installing particulate filters in residential wells to prevent further exposure of the public to PCBs. [7]

Long-term remedial measures were subsequently specified in a 1985 Record of Decision (ROD). Remedial measures were conducted from 1986 until 1991.

Several activities took place relative to the implementation of the ROD requirement of chemical treatment for contaminated soil at Wide Beach.

From May 1986 to February 1989, Ebasco Services, Inc., and Galson Research Corporation conducted bench- and pilot-scale treatability studies to determine the suitability of potassium polyethylene glycol (KPEG) dechlorination as a chemical treatment process. These studies were completed using a batch process, including blending of contaminated soil with KPEG for at least 12 hours, centrifugation of the mixture to recover the dechlorination reagents, and then washing of the soil. [8]

In December 1988, EPA and the United States Army Corps of Engineers (USACE) signed an interagency agreement for the procurement of a remedial action (RA) contractor and management and administration of the RA contract by the USACE. The RA contract developed by the USACE specified that all excavated soils must be treated using a chemical treatment process. Additionally, the contract specified that the concentration of PCBs in soil treated with this process should not be greater than 2 mg/kg and specified that all work be performed in conformance with applicable Federal, State, and local requirements. [8]

In October 1989, Kimmins Thermal Corporation (Kimmins) was awarded the RA contract for the Wide Beach site. Kimmins subsequently submitted a Value Engineering Change Proposal in February 1990 suggesting the use of a continuous process consisting of treatment of soil using SoilTech’s Anaerobic Thermal Process (ATP) combined with EPA’s APEG dechlorination process, instead of the batch KPEG process, for remediating soil at the Wide Beach site. The ATP/APEG process was preferred by Kimmins because the APEG process could be accelerated by the combination of vigorous mixing and higher temperatures in the ATP unit. This process was subjected to a demonstration test in September 1990 and stack gas testing on October 4 and 5, 1990. Based on the results of these tests the ATP/APEG process was found to be acceptable to EPA and the USACE. The soil remediation at the Wide Beach site using the ATP/APEG process was conducted from October 1990 to September 1991. [8]

Regulatory Context: The September 1985 ROD identified the following long-term remedial measures for the site [7]:

Site Management: Fund-Lead (remedial design activities)

USACE-Lead (Contract Administration)

Oversight: EPA

Remedial Project Manager:

Herb King

USEPA, Region 2

26 Federal Plaza

New York, NY 10278

(212) 264-1129

U.S. Army Point of Contact:

Joe Salvatore (primary contact for this application)

USACE

c/o 914 TAG, Building 322

Niagara Falls International Airport

Niagara Falls, NY 14304

(716) 297-8531

Treatment Vendor:

Joseph Hutton

SoilTech ATP Systems, Inc.

800 Canonie Drive

Porter, IN 46304

(219) 926-8651

Back to Executive Summary |

Table of Contents | Forward to Matrix Description

Type of Matrix Processed Through the Treatment System: Soil (ex situ)

The major matrix characteristics affecting cost or performance for this technology and their measured values are presented in Table 1.

Table 1. Matirx Characteristics [9, 28]

| Parameter | Value | Measurement Procedures |

| Soil Classification | Silt/Loam | Not Reported |

| Bulk Density* | 2.10 g/cm | Not Reported |

| Clay Content | 12.8% | ASTM D-421/422 |

| Silt Content | 30.3% | ASTM D-421/422 |

| Moisture Content | 18.3% | ASTM D-2116 |

| pH* | 7.7 | Not Reported |

| Particle Size Distribution*

(cumulative % by weight finer) 4.75 mm 2.0 mm 0.425 mm 0.075 mm 0.005 mm |

85.9 76.2 68.0 48.6 18.8 |

Not Reported |

| Lower Explosive Limit | Not Available | -- |

| Oil and Grease or Total Petroleum Hydrocarbons | Not Available | -- |

*These values are the average results for three composite samples of the contaminated feed collected during the three test runs of the SITE Demonstration conducted in may 1991. These Values are from the SITE Demonstration only, during which 104 of the 42,000 tons of contaminated soil from Wide Beach were tested.

Primary Contaminant Group: PCBs

The concentration of PCBs measured in the soils stockpiled for treatment ranged from approximately 10 to 5,000 mg/kg. PCB concentrations measured in the material fed to the ATP unit ranged from 11 to 68 mg/kg. PCBs were measured in the untreated (stockpiled) soil using EPA Method 8080. [16, 19]

Thermal Desorption/Dehalogenation

Post-treatment (air): The ATP system used at Wide Beach included two off-gas treatment systems.

The flue gas treatment system, designed to treat gases from the combustion zone of the ATP unit, included the following technologies:

The vapor recovery system, designed to treat gases from the preheat and retort zones of the ATP unit, consisted of the following technologies:

Post-treatment (water): The condensed water from the vapor recovery system was treated in an on-site wastewater treatment system utilizing sand filtration, clay and anthracite coal filtration, primary oxidation, gravity settling, secondary oxidation, air stripping, and carbon adsorption.

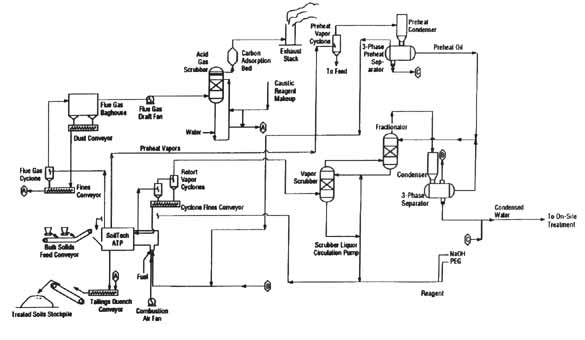

The SoilTech Anaerobic Thermal Processor mobile treatment

system shown in Figure 2 consisted of six main process units including a soil

pretreatment system, a feed system, an anaerobic thermal processor, a vapor

recovery system, a flue gas treatment system, and a tailings handling system.

In addition, the system used at Wide Beach included a reagent preparation

module.

Figure 2. ATP Schematic [9]

APEG reagent and carrier oil solution was sprayed onto the contaminated soil as it entered the ATP unit. APEG reagent was prepared in a module consisting of a reagent storage area, reagent mixing tank, reagent and carrier oil blending tank, and feed pumps. Reagents were mixed and heated in the reagent mixing tank. The reagent solution was then blended with carrier oil in the reagent and carrier oil blending tank.

The feed system consisted of two feed hoppers and a conveyor belt. One feed hopper contained the contaminated soil and the other contained clean sand. The sand served as a heat carrier and was fed to the ATP unit during system startup and shutdown periods.

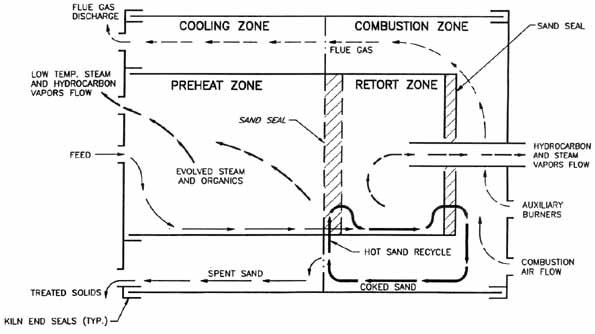

The ATP unit is a rotary kiln containing four separate

internal zones - the preheat, retort, combustion, and cooling zones (shown in

Figure 3). The feed entered the preheat zone where it was heated and mixed,

vaporizing water, volatile organics, and some semivolatile organics. The heated

solids then entered the retort zone where they were further heated, causing

vaporization of heavy oils and some thermal cracking of hydrocarbons, resulting

in the formation of coked solids and decontaminated solids. The coked and

decontaminated solids from the retort zone then entered the combustion zone

where coked solids were combusted. A portion of the decontaminated solids were

recycled to the retort zone via a recycle channel. The recycling of these

solids helped to maintain an elevated temperature in the retort zone. The

decontaminated solids remaining in the combustion zone entered the cooling zone

where they were cooled to an appropriate exit temperature.

Figure 3. Simplified Sectional Diagram Showing the Four Internal Zones [

9 ]

The primary innovative features of the ATP unit are the four internal zones and the use of proprietary sand seals at each end of the retort zone which are designed to maintain an oxygen-free environment in the retort zone, and to prevent the oxidation of hydrocarbons and coke.

The vapor recovery system consisted of two parallel systems. One system condensed water and vapors from the preheat zone of the ATP unit. This system consisted of a cyclone, a condenser, and a gas-oil-water separator. The other system condensed water and vapors from the retort zone and consisted of two cyclones, a fines conveyor, a scrubber, a fractionator, a condenser, and a gas-oil-water separator.

At Wide Beach, condensed water from the vapor recovery system was treated in an on-site wastewater pretreatment system which consisted of the following treatment processes: sand filtration; clay and anthracite coal filtration; primary oxidation using sodium hypochlorite; settling; secondary oxidation with sodium hypochlorite; air stripping; and carbon adsorption. The wastewater discharged from this system was further treated in an off-site commercial treatment system.

The waste oil from the vapor recovery system containing PCBs was dechlorinated using APEG and then recycled as carrier oil in the vapor recovery system. At the end of the project, waste oil remaining in the vapor recovery system was disposed off site.

The flue gas treatment system consisted of a cyclone, fines conveyor, baghouse, dust conveyor, acid gas scrubber and activated carbon unit. This system removed particulates and trace hydrocarbons from the flue gas exiting the combustion zone of the ATP. Fines from the baghouse and cyclone were mixed with the treated solids exiting the ATP unit. The treated flue gas was released to the atmosphere.

The tailings (treated solids) handling system was used to cool and remove treated solids from the ATP. The treated solids exiting the ATP were quenched with process and scrubber water and transported to storage piles using belt and screw conveyors.

The ROD specified that the treated solids were to be used to backfill the excavated areas of the site; however, the treated solids exhibited less cohesiveness than the excavated soil and were not suitable for backfilling. The loss of cohesion was possibly due to the high silt and clay content and the presence of expansive interlayered illite/smectite clay.

At Wide Beach, the ATP unit was operated continuously (24 hours a day and 7 days a week) excluding system down time to repair the mechanical problems discussed below (approximately two months) and to perform routine maintenance (approximately three days per month).

During the treatment application at Wide Beach, the unit was shut down for approximately two months because the inner kiln of the ATP unit cracked due to heat and mechanical stresses during operation. During that time, the geometry and metallurgy of the inner kiln was modified, the burner system was redesigned to reduce heat stresses, and a second drive system was installed to reduce the mechanical stresses on the existing drive system. After making these modifications, the inner kiln did not crack again during the remainder of the treatment application at Wide Beach.

During treatment, problems were encountered with steel debris interfering with the retort zone sand seal in the ATP unit. Also, conglomerated soil was clogging the feed hopper. A soil pretreatment system was added to shred large pieces of conglomerated soil and remove steel debris. The pretreatment system consisted of an asphalt grinder for crushing soil conglomerates to feed particle sizes of less than 2 inches and a magnet for removing steel debris from stockpiled, contaminated soil.

Prior to the demonstration test conducted in September 1990,

SoilTech discovered that a number of the filter bags in the baghouse were torn

due to excessive wear from previous operations. During the test, SoilTech tied

off the damaged bags. SoilTech indicated that the baghouse had adequate

capacity to operate with the damaged bags off-line. After discovering that the

particulate emissions had exceeded the NYDEC air permit level during the

demonstration test, SoilTech determined that several damaged bags had not been

tied off. SoilTech subsequently replaced all of the filter bags in the baghouse

prior to stack gas testing requested by the USACE and conducted the tests on

October 4 and 5, 1990. The average particulate emissions measured during the

October 1990 stack gas tests (0.03 gr/dscf, based on three stack gas tests)

were less than one-tenth the average particulate emissions measured during the

September 1990 stack gas tests (0.32 gr/dscf, based on two stack gas

tests).

The major operating parameters affecting treatment cost or performance for this technology and their values measured during this treatment application are presented in Table 2.

Table 2. Operating Parameters* [9, 25]

| Parameters | Value | Measurement Method |

| Operating Pressure | Negative Pressure | Not Available |

| Preheat and Rtort Zone Residence Time | 30 - 40 minutes | Not Available |

| Retort Zone Temperature | 1,160 F | Thermocouples in the Retort Zone |

| Combustion Zone Temperature | 1,293 F | Thermocouples in the Combustion Zone |

| Cooling Zone Temperature | 434 F | Thermocouples in the Cooling Zone |

| System Throughput | Not Available | Not Available |

*The values presented in Table 2 are the average results for the three test runs of the SITE Demonstration. According to the USACE, these values were held fairly constant during the entire course of the soil remediation at Wide Beach. [9, 25]

Other parameters measured during the SITE Demonstration were the stack gas flow rate (5,275 standard cubic feet per minute (scfm)) and the preheat and retort zone off-gas flow rates (203 and 109 actual cubic feet per minute (acfm), respectively). [9]

The timeline for this application is presented in Table 3.

Table 3. Timeline

| Start Date | End Date | Activity |

| September 30, 1985 | -- | ROD signed |

| May 1986 | February 1989 | Treatability Studies of KPEG conducted |

| September 7, 1990 | September 8, 1990 | Demonstration test of the ATP/APEG process performed |

| October 4, 1990 | October 5, 1990 | Stack gas tested for particulate emissions. |

| October 1990 | September 1991 | Full-scale operation of the ATP/APEG process |

| December 1990 | January 1991 | System shut down - the inner kiln of the ATP unit cracked due to thermal and mechanical stresses. The geometry and metallurgy of the inner kiln was imporved to allow use of combustion zone temperature up to 1,500 F. |

| May 1991 | -- | SITE Demonstration conducted |

Back to Matrix Description | Table of Contents | Forward to Treatment System Performance

The Remedial Action (RA) contract developed by USACE specified a maximum concentration of 2 mg/kg for PCBs in treated soil and that all remediation work be performed in conformance with applicable Federal, State, and local requirements. [17]

Applicable Federal, State, and local requirements include air emission requirements for stack gases. The New York Department of Environmental Conservation (NYDEC) specified the following stack emission requirements for the ATP unit used at Wide Beach [4]:

The ROD specified that contaminated soils from roadways, drainage ditches, driveways, yards, and wetlands containing more than 10 mg/kg of PCBs were to be excavated and chemically treated.

The RA contract required a PCB cleanup level of 2 mg/kg be verified by collecting one sample from the treated soil staging area for every 100 tons of soil treated. These samples were collected by inserting a stainless steel tube into the staging pile. [17, 19]

Table 4 summarizes the analytical results for PCBs (measured in an on-site laboratory using EPA Method 8080) in untreated and treated soil during the treatment application at Wide Beach. [19, 24]

| Range of PCB Concentrations (mg/kg) | Number of Data Points | Number of Detects | Number of Detects Greater than 2 mg/kg | |

| Untreated soil | 11-68 | 42 | 41 | 41 |

| Treated soil | ND(0.4)-21 | 520 | 196 | 0 |

ND=Not detected. Number in parentheses is the

reported detection limit.

Results for stack gas emissions of PCBs, PEG, and particulates are presented in Appendix A.

Although no treatment standard or action level was set for

dioxins/furans in stack gas emissions, these constituents were measured in the

SITE Demonstration. [28] Table 5 shows dioxin and furan stack gas emissions measured during

the SITE Demonstration. [9]

Table 5. Dioxin and Furan Stack Gas Emissions [9]

| Compound | Stack Gas (ng/dscm) |

| Tetrachlorinated dibenzo-p-dioxins (TCDD) | 0.14 |

| Tetrachlorinated dibenzofurans (TCDF) | 4.8 |

| Pentachlorinated dibenzo-p-dioxins (PeCDD) | 0.96 |

| Pentachlorinated dibenzofurans (PeCDF) | 0.72 |

| Hexachlorinated dibenzo-p-dioxins (HxCDD) | 0.17 |

| Hexachlorinated dibenzofurans (HxCDF) | 0.077 |

| Heptachlorinated dibenzo-p-dioxins (HpCDD) | 0.25 |

| Heptachlorinated dibenzofurans (HpCDF) | 0.032 |

| Octachlorinated dibenzo-p-dioxins (OCDD) | 2.34 |

| Octachlorinated dibenzofurans (OCDF) | 0.032 |

| TOTAL | 9.52* |

*Total stack gas concentration of 9.52 ng/dscn us equivalent to a 2,3,7,8-TCDD concentration of 0.707 ng/dscm.

The concentrations of PCBs in treated soil samples ranged from less than the reported detection limit (generally equal to 0.4 to 0.5 mg/kg) to 1.8 mg/kg. The concentrations of PCBs in treated soil samples were generally less than or equal to the detection limit of 0.4 to 0.5 mg/kg.

The level of dechlorination in the ATP unit was measured during the demonstration test conducted in September 1990 (see Appendix A), and the SITE Demonstration conducted in May 1991. The level of dechlorination was determined by comparing the quantity of PCBs entering the ATP system to the quantity of PCBs discharged from the ATP system via all effluent streams - the treated solids, stack gas, condensed water, and vapor scrubber oils, and assuming that the difference in mass of PCBs is attributed to dechlorination. During the demonstration test, 4.3 pounds of PCBs entered the system and 1.05 pounds of PCBs were discharged, corresponding to a 76 percent dechlorination level (i.e., 76 percent of the mass of PCBs entering the system were dechlorinated). However, this figure does not account for dechlorination from the recycle of residual oil through the system. During the SITE Demonstration, 0.321 lb/hr of PCBs were fed to the ATP system and 0.00678 lb/hr of PCBs were discharged from the ATP system, corresponding to a 98 percent dechlorination level. [4, 9]

During the Demonstration Test, stack gas emission requirements were met for PCBs, PEG, and particulates.

The performance data are suitable for characterizing the concentrations of PCBs in untreated and treated soil, and for comparing treatment performance with system design and operation. The demonstration test and the SITE Demonstration test include paired, representative untreated and treated soil samples.

Approximately 10% of the treated soil samples collected during the treatment application at Wide Beach were split for analysis in both the on-site laboratory and the USACE’s New England Division laboratory. The on-site laboratory results generally compared well with the USACE results. In some instances the on-site laboratory results below 1 mg/kg PCBs showed a negative bias when compared to the USACE laboratory results; however, none of the data were rejected by the USACE. [20-23]

Back to Treatment System Description | Table of Contents | Forward to Treatment System Cost

EPA and the USACE signed an interagency agreement for the procurement of an RA contractor. The interagency agreement specified that the USACE would be responsible for management and administration of the RA contract. The USACE retained Kimmins Thermal Corporation to manage the remedial construction and treatment activities at the site. Kimmins subcontracted SoilTech, Inc., to treat the excavated contaminated soil at Wide Beach using the ATP/APEG dechlorination process. [8]

Tables 6, 7, and 8 present the costs for the Thermal Desorption/Dehalogenation application at the Wide Beach Development Superfund Site. In order to standardize reporting of costs across projects, costs are shown in Tables 6, 7, and 8 according to the format for an interagency Work Breakdown Structure (WBS). The WBS specifies 9 before-treatment cost elements, 5 after-treatment cost elements, and 12 cost elements that provide a detailed breakdown of costs directly associated with treatment. Tables 6, 7, and 8 present the cost elements exactly as they appear in the WBS, along with the specific activities, and unit cost and number of units of the activity, as provided by EPA in the draft Applications Analysis Report.

In preparing the Applications Analysis Report, EPA obtained

actual cost data from Soil Tech for treating 42,000 tons of soil at Wide Beach

[9]. As shown

in Table 6, the cost data show a total of $11,600,000 for cost elements

directly associated with treatment of the soil (i.e., excluding before- and

after-treatment cost elements). This total treatment cost corresponds to $280

per ton of soil treated. In addition, Tables 7 and 8 show that a total of

$908,000 for before-treatment and $3,400,000 for after-treatment costs were

incurred. There were no costs in this application for the following elements in

the WBS: Liquid Preparation and Handling, Vapor/Gas Preparation and Handling,

Pads/Foundations/Spill Control, Training, Operation (Long-term - over 3 years),

Site Work, Surface Water Collection and Control, Groundwater Collection and

Control, Air Pollution/Gas Collection and Control, Solids Collection and

Containment, Liquids/Sediments/Sludges Collection and Containment,

Drums/Tanks/Structures/Miscellaneous Demolition and Removal, Decontamination

and Decommissioning, Disposal (Other than Commercial), Site Restoration, and

Demobilization.

Table 6. Costs Directly Associated with Treatment [9]*

| Cost Elements | Cost (dollars) |

| Solids Preparation and Handling --residuals and waste handling and transporting |

736,000 |

| Startup/Testing/Permits --permitting and regulatory --startup |

200,000 133,000 |

| Operation (short-term - up to 3 years) --labor --supplies and consumables --utilities --equipment repair and replacement |

3,800,000 1,194,000 913,000 1,982,000 |

| Cost of Ownership --capital equipment |

2,153,000 |

| Demobilization | 481,000 |

| TOTAL TREATMENT COST | 11,600,000 |

Calculated Cost per Ton Soil Treated: $280 per ton

*Additional information on estimated costs is available in Reference [26].

Table 7. Before-Treatment Cost Elements

| Cost Elements | Cost (dollars) |

| Mobilization and Preparatory Work --transport of ATP unit to site --initial setup --installing infrastructure for utilities --setup of decontamination facilities |

588,000 |

| Monitoring, Sampling, Testing, and Analysis | 320,000 |

Table 8. After-Treatment Cost Elements [9]

| Cost Elements | Cost (dollars) |

| Disposal (commercial) | 3,400,000* |

*Calculated from a disposal cost of $80/ton x 42,000 tons of soil treated.

Treatment cost information shown in Table 6 represents actual costs of the treatment application and was obtained from the treatment vendor. No qualifications to the cost information were provided by the vendor. [9]

According to the treatment vendor, in general, the costs for treatment using the SoilTech ATP system vary depending on the character of the waste material, with treatment costs ranging from $150 to $250 per ton for a 10-ton per hour ATP system. The factors identified by the vendor that affect costs include:

Vendor estimates for mobilization and demobilization costs for a 10-ton per hour system range from $700,000 to $1.5 million. In the three Superfund projects completed by the SoilTech ATP System since the Wide Beach project, no off-site disposal of treated solids has been required. In addition, treatment costs have been reduced by as much as 17% as a result of improved process efficiency.

Back to Treatment System Performance | Table of Contents | Forward to Observations and Lessons Learned

the average concentration of nitrogen was reduced from 733 in the untreated soil to 40 mg/kg in the treated solids during the SITE Demonstration;

the treated solids contained an elevated concentration of soluble salts due to the addition of the APEG reagents; and

- the pH of the treated soil required adjustment.

Back to Treatment System Cost | Table of Contents | Forward to References

This case study was prepared for the U.S. Environmental Protection Agency's Office of Solid Waste and Emergency Response, Technology Innovation Office. Assistance was provided by Radian Corporation under EPA Contract No. 68-W3-0001.

Back to Observations and Lessons Learned | Table of Contents | Forward to Appendix A - Demonstration Test

Demonstration Test Purpose

The purpose of this test was to:

Demonstration Test Description

The treatment system used for the full-scale remediation of soil at the Wide Beach site was used for the demonstration test, as described in the ATP/APEG Process Description and Operation section of this report.

The demonstration scale test was conducted on September 7 and 8, 1990 and consisted of two phases. The first phase included processing of approximately 62 tons of contaminated soil through the treatment system and occurred during the first ten hours of the test. The second phase included the processing of clean sand feed while recycling recovered oils containing PCBs with the dechlorination reagents. The second phase occurred during the last 11 hours of the demonstration. The purpose of the second phase was to collect data which showed that dechlorination was occurring during the treatment process by isolating the dechlorination of PCBs contained in the recycled water and oil.

Demonstration Performance Data [4]

As shown in Tables A-1 and A-2, the demonstration scale test results indicated that the site cleanup goal for PCBs in soil (less than 2 mg/kg) and stack gas emissions requirements were achieved using the ATP dechlorination treatment system.

Table A-1. Removal of PCBs for Contaminated Soil [4]

| Concentration of PCBs in the Contaminated Feed Composite Sample (mg/kg) | Concentration of PCBs in the Treated Solids Composite Sample (mg/kg) | Cleanup Goal for PCBs in Soil (mg/kg) | Percent Removal (%) |

| 25 | <0.06 | <2.0 | >99 |

Table A-2. Stack Gas Emissions [4]

| Constituent | Requirement | Maximum Emission Levels |

| PCB (lb/hr) | 3.33 x 105 | 1.0 x 105 |

| PEG (lb/hr) | 4.16 x 105 | 4.0 x 105 |

| Particulates (gr/dscf) | 0.05 | 0.04 |

Analyses of the TCLP extracts from the treated solids indicated that metals,

herbicides, semivolatile organics, pesticides, and volatile organics were not

present in the extracts above the TC limits. Additionally, total petroleum

hydrocarbons were not detected in the treated solids (detection limit equal to

4.6 mg/Kg).

The occurrence of dechlorination was quantified by analyzing PCB material balance data for the demonstration test. During the first phase of the demonstration, approximately 4.3 pounds of PCBs were fed into the treatment system, 0.0151 pounds were discharged in the treated soils and stack emissions, and 1.03 pounds accumulated in the system (in process oil and water). The percentage of PCBs introduced into the treatment system that were dechlorinated is calculated by the following equation:

These results indicate that approximately 76 percent of the PCBs introduced into the system were dechlorinated during the first phase of the demonstration test.

During the first phase of the demonstration test, recovered oils were commingled with oils produced during the pretest run and reagent fuel. This increased the volume of oil to be recycled during the second phase. As a result, only 20% of the recovered oils could be recycled during the test. Consequently, the second phase of the demonstration test could not provide conclusive evidence of dechlorination of the recycled oils.

During the first phase of the demonstration test, 61.66 tons of contaminated soil were treated in the ATP system in 7.62 hours. This corresponds to an average feed rate of 8.1 tons per hour (tph). The maximum feed rate during the first phase of the demonstration test was 8.92 tph for approximately 1.5 hours.

Demonstration Test Lessons Learned