(Vacuum-Vaporized Well System)

TECHNOLOGY DESCRIPTION:

The SBP Technologies, Inc. (SBP), remediation program uses an in situ Unterdruck- Verdampfer-Brunnen (UVB) vertical groundwater circulation well technology, which has been enhanced with an in situ bioreactor to treat contaminated soil and groundwater. This process consists of a specially adapted groundwater circulation well, reduced pressure stripping reactor, an in situ bioreactor, and an aboveground vapor-phase bioreactor.

The UVB technology was developed by IEG mbH in Germany and is distributed in the U.S. by IEG Technologies Corporation. SBP obtained the exclusive rights to implement this technology and enhanced it to create a more effective in situ bioremediation technology.

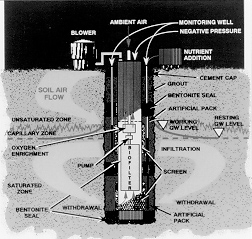

The microbiologically enhanced vertical circulation well technology simultaneously treats the vadose zone, capillary fringe, and saturated zones. During the demonstration, a groundwater convection (circulation) cell was created radially within the aquifer around the 16-inch UVB well. The UVB well consisted of upper and lower screens separated by a solid riser casing (see the figure below). The lower screen was isolated from the upper screen by a packer, creating two separate screened zones. Contaminated groundwater flowed into the lower screen of the UVB well and was pumped to the upper section. The water rose through the in situ fixed film bioreactor, initially reducing the contaminant load. Groundwater then flowed to the in situ aerator/stripping reactor, where fresh ambient air was mixed with the contaminated groundwater.

Vacuum-Vaporized Well (UVB) System Standard Circulation

The convection cell was developed by allowing the treated groundwater to exit into the upper aquifer. The untreated volatile organic compounds (VOC) exiting the in situ bioreactor system were stripped before the groundwater flowed out of the upper screen into the aquifer as clean water. Oxygenated groundwater from the shallow aquifer circulated to the deep aquifer zone and through the fixed film bioreactor to provide for aerobic degradation. This circulation created an 80-foot-diameter remediation circulation cell in a glacial till geologic formation.

In conjunction with the groundwater remediation, the upper double-cased screen in the well allowed for a one-way soil air flow from the vadose zone to the UVB. This one-way soil venting, created by the reduced pressure developed in the well by the blower, remediated the contaminated unsaturated and capillary fringe zones simultaneously.

The off-gases from the in situ aerator/stripping reactor passed through an ex situ gas phase bioreactor for further biotreatment followed by granular activated carbon treatment before being vented. This bioreactor consisted of spirally wound, microporous, polyvinyl chloride-silica sheets that served as a biosupport for Pseudomonas cepacia (strain 17616), a known trichloroethene (TCE) degrader. VOCs in the off-gases, such as toluene, benzene, xylene, TCE, and others were also biologically treated through a cometabolic process in the gas phase bioreactor.

WASTE APPLICABILITY:

This technology treats soil and groundwater contaminated with chlorinated and nonchlorinated VOCs.

STATUS:

The UVB system was accepted into the SITE Demonstration Program in June 1994. The pilot-scale, multivendor treatability demonstration (MVTD) was jointly sponsored by the New York State Department of Environmental Conservation (NYSDEC), the New York State Center for Hazardous Waste Management, and the SITE Program. The objectives of the MVTD were to (1) generate field data for three biological processes, and (2) evaluate the performance of each biological process in meeting NYSDEC cleanup goals.

The demonstration took place at the Sweden 3-Chapman site in Sweden, New York. Field work began in July 1994 and was completed in fall 1995. Final reports from the demonstration will be available in 1997.

The UVB demonstration coincided with the remediation of the site. Soil at the site contained elevated levels of TCE, acetone, tetrachloroethene, dichloroethene, and toluene. The contaminants of concern (COC) were monitored at 15 groundwater monitoring wells, across the in situ bioreactor, the vadose zone soils, and the ex situ bioreactor to evaluate the system's performance. A dye tracer test was conducted to determine the extent of the groundwater circulation cell.

In addition to the SBP process, the following technologies were also

demonstrated:

R.E. Wright Environmental, Inc., In Situ Bioventing Treatment System

ENSR Consulting and Engineering and Larsen Engineers Ex Situ Biovault

For information on these technologies, refer to the NYSDEC profiles in the Demonstration Program section (completed projects).

DEMONSTRATION RESULTS:

During the demonstration, an in situ vertical groundwater circulation cell was established with an effective radius of 40 feet. The UVB system reduced the concentration of COCs in groundwater. The in situ bioreactor provided biotreatment of the COCs in the dissolved phase. Also, removal of COCs from soils was demonstrated. An ex situ bioreactor was effective in treating off-gas vapors from the UVB system prior to final polishing. Mass balance calculations determined that at least 75 percent of the target COCs in soil and groundwater, within the UVB's radius of influence, were removed during the demonstration.

FOR FURTHER INFORMATION:

EPA PROJECT MANAGER:

Michelle Simon

U.S. EPA

National Risk Management Research Laboratory

26 West Martin Luther King Drive

Cincinnati, OH 45268

513-569-7469

Fax: 513-569-7676

TECHNOLOGY DEVELOPER CONTACTS:

Nick Kolak

New York State Department of Environmental Conservation

50 Wolf Road, Room 268

Albany, NY 12233-7010

518-457-3372

Fax: 518-457-7743

Richard Desrosiers

SBP Technologies, Inc.

106 Corporate Park Drive

White Plains, NY 10604

914-694-2280

Fax: 914-694-2286