(VaporSep® Membrane Process)

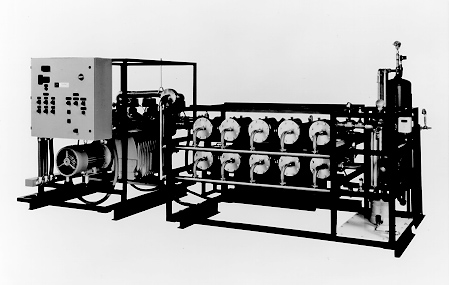

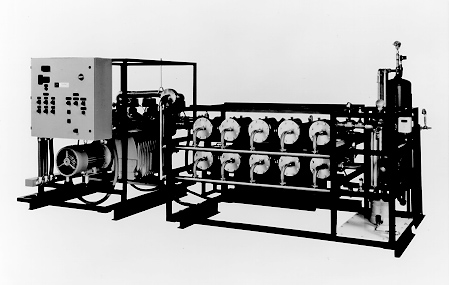

The Membrane Technology and Research, Inc., VaporSep® system, shown in the figure below, uses synthetic polymer membranes to remove organic vapors from contaminated air streams. The process generates a clean air stream and a liquid organic stream.

VaporSep® Membrane Organic Vapor Recovery Process

Air laden with organic vapor contacts one side of a membrane that is 10 to 100 times more permeable to the organic compound than to air. The membrane separates the air into two streams: a permeate stream containing most of the organic vapor, and a clean residual air stream. The organic vapor is condensed and removed as a liquid; the purified air stream may be vented or recycled.

The VaporSep® system maintains a lower vapor pressure on the permeate side of the membrane to drive the permeation process. This pressure difference can be created by either compressing the feed stream or using a vacuum pump on the permeate stream.

The VaporSep® systems built to date range in capacity from 1 to 700 standard cubic feet per minute. The systems are significantly smaller than carbon adsorption systems of similar capacity and can be configured for a wide range of feed flow rates and compositions. The process has been tested on air streams contaminated with a wide range of organic compounds at concentrations of 100 to over 100,000 parts per million.

The VaporSep® system removes between 90 and 99 percent of the organic vapor, depending on the class of organic compound and the system design. The system produces only a purified air stream and a small volume of organic condensate. The concentration of organics in the purified air stream is generally low enough for discharge to the atmosphere.

VaporSep® systems can treat most air streams containing flammable or

nonflammable halogenated and nonhalogenated organic compounds, including

chlorinated hydrocarbons, chlorofluorocarbons (CFC), and fuel hydrocarbons.

Typical applications include the following:

This technology was accepted into the SITE Emerging Technology Program in 1989; the project was completed in 1991. The process, demonstrated at both the bench and pilot scales, achieved removal efficiencies of over 99.5 percent for selected organic compounds. The Emerging Technology Bulletin (EPA/540/F-94/503) is available from EPA.

Almost 40 VaporSep® systems have been supplied to customers in the United

States and overseas for applications such as the following:

A VaporSep® system successfully treated an air stream from a soil vacuum extraction operation at a U.S. Department of Energy site.

EPA PROJECT MANAGER:

Paul dePercin

U.S. EPA

National Risk Management Research Laboratory

26 West Martin Luther King Drive

Cincinnati, OH 45268

513-569-7797

Fax: 513-569-7105

E-Mail:

dePercin.Paul@epamail.epa.gov

TECHNOLOGY DEVELOPER CONTACTS:

Marc Jacobs

Doug Gottschlich

Membrane Technology and Research, Inc.

1360 Willow Road

Menlo Park, CA 94025-1516

415-328-2228

Fax: 415-328-6580

E-mail: mjacobs@mtrinc.com