(formerly BIO-RECOVERY SYSTEMS, INC.)

(AlgaSORB© Biological Sorption)

The AlgaSORB© sorption process uses algae to remove heavy metal ions from aqueous solutions. The process takes advantage of the natural affinity for heavy metal ions exhibited by algal cell structures.

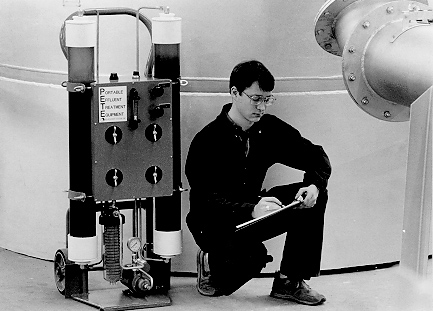

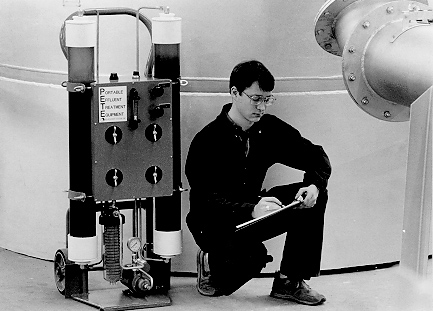

The photograph below shows a portable effluent treatment equipment (PETE) unit, consisting of two columns operating either in series or in parallel. Each column contains 0.25 cubic foot of AlgaSORB©, the treatment medium. The PETE unit shown below can treat waste at a flow rate of approximately 1 gallon per minute (gpm). Larger systems have been designed and manufactured to treat waste at flow rates greater than 100 gpm.

Portable Effluent Treatment Equipment (PETE) Unit

The AlgaSORB© medium consists of dead algal cells immobilized in a silica gel polymer. This immobilization serves two purposes: (1) it protects the algal cells from decomposition by other microorganisms, and (2) it produces a hard material that can be packed into columns that, when pressurized, still exhibit good flow characteristics.

The AlgaSORB© medium functions as a biological ion-exchange resin to bind both metallic cations (positively charged ions, such as mercury [Hg+²]) and metallic oxoanions (negatively charged, large, complex, oxygen-containing ions, such as selenate [SeO4-²]). Anions such as chlorides or sulfates are only weakly bound or not bound at all. In contrast to current ion-exchange technology, divalent cations typical of hard water, such as calcium (Ca+²) and magnesium (Mg+²), or monovalent cations, such as sodium (Na+) and potassium (K+) do not significantly interfere with the binding of toxic heavy metal ions to the algae-silica matrix.

Like ion-exchange resins, AlgaSORB© can be regenerated. After the AlgaSORB© medium is saturated, the metals are removed from the algae with acids, bases, or other suitable reagents. This regeneration process generates a small volume of solution containing highly concentrated metals. This solution must undergo treatment prior to disposal.

This technology can remove heavy metal ions from groundwater or surface leachates that are "hard" or that contain high levels of dissolved solids. The process can also treat rinse waters from electroplating, metal finishing, and printed circuit board manufacturing operations. Metals removed by the technology include aluminum, cadmium, chromium, cobalt, copper, gold, iron, lead, manganese, mercury, molybdenum, nickel, platinum, selenium, silver, uranium, vanadium, and zinc.

This technology was accepted into the Emerging Technology Program in 1988; the evaluation was completed in 1990. Under the Emerging Technology Program, the AlgaSORB© sorption process was tested on mercury-contaminated groundwater at a hazardous waste site in Oakland, California. Testing was designed to determine optimum flow rates, binding capacities, and the efficiency of stripping agents. The Emerging Technology Report (EPA/540/5-90/005a&b), Emerging Technology Summary (EPA/540/S5-90/005), and Emerging Technology Bulletin (EPA/540/F-92/003) are available from EPA. An article was also published in the Journal of Air and Waste Management, Volume 41, No. 10, October 1991.

Based on results from the Emerging Technology Program, Resource Management & Recovery was invited to participate in the SITE Demonstration Program.

The process is being commercialized for groundwater treatment and industrial point source treatment.

EPA PROJECT MANAGER:

Ronald Lewis

U.S. EPA

National Risk Management Research Laboratory

26 West Martin Luther King Drive

Cincinnati, OH 45268

513-569-7856

Fax: 513-569-7105

TECHNOLOGY DEVELOPER CONTACT:

Michael Hosea

Resource Management & Recovery

4980 Baylor Canyon Road

Las Cruces, NM 88011

505-382-9228

Fax: 505-382-9228