Pilot-Scale Bioreactive PRB Removes Metals from Ground-Water Plume Within One Year

CLU-IN Resources

The U.S. EPA's Technology Innovation and Field Services Division continuously updates CLU-IN's Technology Focus, an online compilation of "bundled" information on 19 categories of remediation technologies including bioreactor landfills, permeable reactive barriers, electrokinetics, soil washing/mixing, soil vapor extraction, and thermal desorption. An overview of each bundled category is provided, along with associated guidance, case studies, and listings of additional resources. Technology Focus is available at http://www.cluin.org/techfocus.

The South Carolina Department of Health and Environmental Control (SCDHEC) recently completed a field-scale pilot study on the use of an in-situ sulfate-reducing bioreactor/permeable reactive barrier (SRBR/PRB) to address metals contamination in ground water at the Stoller Chemical Site in Jericho, SC. The SRBR/PRB contains common biomaterial such as coastal hay, woodchips, and livestock manure that encourages growth of sulfate-reducing bacteria, thereby passively treating influent ground water. The study evaluated the technology’s effectiveness based on achievement of maximum contaminant levels (MCLs) within the SRBR/PRB, hydraulic performance of the system, longevity of such a passive system, presence or absence of plugging from aluminum hydroxide or metallic precipitates, constructability, and potential cost savings.

Past fertilizer manufacturing operations at the site resulted in low pH and metals contamination in a shallow aquifer 2-18 ft below ground surface (bgs) that overlies a clay confining unit of variable thickness. Primary metals of concern are cadmium, copper, nickel, manganese and zinc, and to a lesser extent, aluminum and iron. Sampling and analysis indicated that the metals have not migrated to the aquifer below the clay unit. The 900-ft-long contaminant plume extends from the site northward, across North Creek to Caw Caw Swamp. Migration of the excess dissolved metals in the plume was greatly enhanced by the area’s high oxidation/reduction potential (ORP) of approximately 300 mV. As a result, a 22-gpm interim pump and treat system began operating in 2002 to address the source area, which is located approximately 400 ft upgradient of the pilot project. Based on the soil’s effective porosity of 0.26 and an average gradient of 0.012 ft/ft, the average linear ground-water velocity for the aquifer while undergoing treatment is estimated to be 0.36 ft/day.

SRBR/PRB technology employs sulfate-reducing bacterial reactions that generate sulfide ions. These combine with dissolved metals to precipitate sulfide compounds and bicarbonate, which raises the effluent pH to a neutral 5.0-6.0. The bioreactive medium includes limestone to provide bicarbonate alkalinity and to buffer initial pore water solutions against pH drops associated with fermentation. Earlier studies showed that sulfate-reducing bacteria such as Desulfovibrio account for less than 1% of the total bacterial community needed in an effective in-situ bioreactor.

A six-month bench-scale evaluation was conducted in five test cells at the Stoller site in early 2004. Metals-impacted ground water from an existing monitoring well was added to each cell, which were filled with different ratios of reactive materials. Results indicated 99.3-99.8% removal of metals. Construction of the pilot-scale system began soon afterward in mid 2004. Prior to excavating the barrier trench, ground-water screening using direct-push technology was conducted to ensure SRBR/PRB placement within and perpendicular to the contaminant plume. Reinforced-steel sheet piling was installed in the subsurface in a 21-by-11.5-ft rectangular configuration extending 15 ft bgs. Six clusters of three monitoring points (at depths of 6.5-7.5, 8.5-9.5, and 10.5-11.5 ft bgs) were installed in the trench prior to its filling.

Based on the bench-scale results, the selected reactive media consisted of a mixture of 32.4% (by volume) coastal hay, 19.3% hardwood chips, 19.3% softwood chips, 16.6% saw dust, 7% limestone, 5.5% horse manure, and 0.4% cement kiln dust. The media were mixed onsite, emplaced in the trench, compacted to within 1.5 ft of ground surface, saturated with plume ground water, and incubated for 33 days. The sheet-pile walls then were removed to allow natural ground-water flow through the completed 10-ft-wide PRB. Ground-water flow was enhanced by the higher permeability of the reactive media. Loading of the trench occurred at a rate of 2.7 gal/day/ft², and an estimated 554 gal of ground water flowed through the barrier each day thereafter. Hydraulic monitoring was performed within and outside the treatment area, and no significant changes in water levels, hydraulic gradient, or hydraulic conductivity were noted during the study period.

Two core samples of the barrier media from the upgradient side of the trench were collected after one year of treatment. Visual inspection showed saturation and blackening of the biomass, but the coastal hay and wood chips, which accounted for 71% of the original biobarrier volume, appeared intact and without significant structural degradation. Approximately 5% of the organic material, primarily the manure, had been consumed. The lack of evidence of gypsum or aluminum hydroxide precipitation suggested that barrier plugging had not occurred. Examination of the barrier core samples with a scanning electron microscope revealed no visible precipitates. Analysis of particle surfaces with an electron microprobe, however, confirmed the presence of metals on the surface of the media near the base of the aquifer.

In addition to the 18 monitoring points within the wall, three upgradient and five downgradient monitoring points were used for routine testing of target metal concentrations and of ground-water parameters such as pH, ORP, conductivity, and temperature. Seven ground-water sampling rounds were conducted between August 2004 and July 2005. Sample data suggested that the geochemical conditions inside the trench mimicked the conditions observed in the bench-scale tests. Pore water pH was consistently 5.5-7.0, and reducing ORP conditions consistently were conducive to bacterial sulfate reduction (< -200 mV). Ambient ground-water temperatures initially warmed due to incubation prior to removal of the sheet piling but cooled to background conditions over a period of weeks after removal of the sheet piling.

Additional testing was conducted to evaluate the treatment system’s impact beyond the study area and on other environmental media. The absence of fecal coliform bacteria in any of the five downgradient monitoring points indicated that the use of manure as a reactive medium did not induce viable colonies of fecal coliform in the aquifer after one year of treatment. To evaluate potential air emissions, a photoionization/flame ionization detector and a four-gas air monitor were used to evaluate the headspace of each monitoring point. Results showed no detrimental emissions of methane, hydrogen sulfide, methane, hydrogen sulfide, or carbon monoxide.

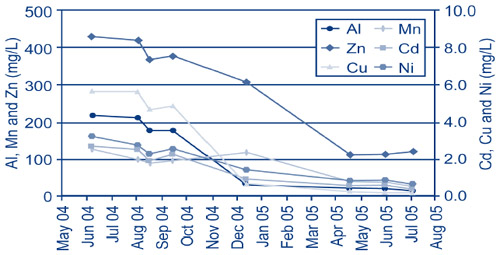

As expected, metal concentrations in the trench met MCLs and achieved the remedial goal of a 90% reduction in metals of concern. Time series graphs derived from data collected at one downgradient monitoring point (representing a mixture of treated effluent from the wall and contaminated water in place) demonstrate an approximate 84%, 96%, and 72% reduction of cadmium, copper, and zinc, respectively (Figure 1).

The long-term effectiveness and longevity of the SRBR/PRB will depend on factors such as the rate of ground-water flow through the trench, influent ground-water characteristics, and quantity of organic matter supplying total organic carbon. A lifespan of 12-16 years currently is projected. Development of a feasibility study is underway for two scaled-up biobarriers that address offsite portions of the plume and replace the existing pump and treat system. SCDHEC estimates that use of the sulfate-reducing PRB will achieve a $1-2 million savings over the cost of expanding the pump and treat system for the downgradient portion of the plume. If the entire pump and treat system is replaced, cost savings of several million dollars are anticipated due to a significant reduction in operation and maintenance costs that currently average approximately $400,000/yr.

Contributed by Judy Canova, SCDHEC (canovajl@dhec.sc.gov or 803-896-4046)

ZVI-Clay Soil Mixing Treats DNAPL Source Area at 35-Foot Depth

Over the past several years, Colorado State University (CSU) collaborated with private industry to develop a technology that involves in-situ admixing of contaminated soil, granular zero-valent iron (ZVI), and clay using conventional soil mixing equipment. A full-scale application of this technology was conducted in 2002 at a former nylon manufacturing facility in Martinsville, VA, where carbon tetrachloride (CT) concentrations averaged 4,000,000 µg/kg. Post-treatment soil analyses indicated 99% removal of CT and total chlorinated volatile organic compounds (CVOCs) after one year of treatment. Field tests also showed that treatment significantly reduced soil permeability and thereby limited the release of remaining contaminants into ground water.

The treatment area comprised a 70-by-100-ft source area with 8,000 yd³ of soil initially containing an estimated 20 tons of CT. The area is underlain by 15-20 ft of alluvium overlying 10-20 ft of saprolite that grades to bedrock at approximately 35 ft bgs. During soil mixing, boulders were encountered at a depth of 25 ft in a small portion of the treated interval and subsequently excavated.

Mixed soil columns were constructed using a crane-mounted drill system equipped with an 8-ft-diameter soil auger. A clay/water grout was combined onsite with granular ZVI, and the mixture was blended with subsurface soil through multiple auger passes. A total of 76 mixed soil columns extending 35 ft bgs were created over 10 weeks.

Treatment required approximately 225 tons of ZVI as a reactive medium and 340 tons of kaolin clay as a stabilizing agent. Target amounts of ZVI varied from 2 to 6 lbs/ft³ soil, with higher amounts added in contaminant hot spots. After mixing, the upper 5 ft of treated soil were remixed with Portland cement to improve load-bearing capacity. An asphalt cap was constructed over the entire treatment area six months later.

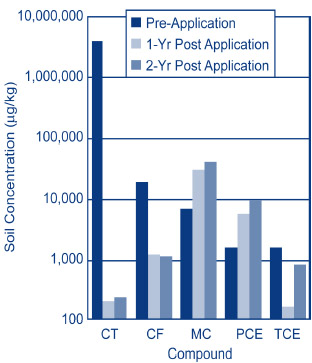

Twenty soil cores from the treated interval were collected and analyzed the following year and again in 2004. Samples were analyzed for CT and potential daughter products, including chloroform (CF), methylene chloride (MC), chloromethane (CM), tetrachloroethene (PCE), and trichloroethene (TCE). After one year of treatment, the average concentration of CT in soil had decreased from 4,000,000 µg/kg to 210 µg/kg (Figure 2). Concentration increases in most daughter products, particularly MC, indicated that ZVI-mediated reductive dechlorination had occurred. Rates of daughter compound production were found to depend on factors such as amenability to ZVI reaction and sorption in the soil matrix. Contaminant concentrations detected in the second annual sampling event indicated that the reaction had apparently ceased or slowed.

To characterize the remaining iron, granular iron was magnetically separated from soil obtained during the second annual sampling event. Laboratory analysis indicated that most of the granular iron mass remained, and a batch study confirmed that it was still capable of degrading chlorinated compounds. These results suggest that the remaining contaminant mass is irreversibly adsorbed in the soil matrix and consequently unavailable for reaction or migraAtion through downgradient water.

Permeability of the aquifer was measured at 10-3 to 10-2 cm/s prior to treatment. Post-treatment samples collected from one mixed soil column at depths of 10, 20, and 30 ft showed an average permeability of 2.9 x 10-7 cm/s, indicating a permeability reduction of four to five orders of magnitude. This reduction suggested that ground-water flow selectively bypassed the treated interval and allowed for containment of the contaminant mass, an increase in contaminant residence time, and a reduced inflow of competing oxidative agents.

Implementation of this technology requires sufficient overhead space to operate the mixing equipment and remove buried obstructions. Completed applications suggest that soil mixing technologies such as this can be used at depths reaching 100 ft bgs but are most effective at depths less than 40 ft bgs. Costs for construction (including equipment, materials, and labor) were estimated at $80/yd³ of treated soil at the Martinsville site. Similar ZVI-clay projects were initiated last year at Camp Lejeune, NC, and Arnold Air Force Base, TN. CSU’s ongoing ZVI-clay research focuses on improving post-treatment soil strength and enhancing methods for performance monitoring. The U.S. EPA’s National Risk Management Research Laboratory (NRMRL) plans to further evaluate the technology’s performance as part of a technology demonstration anticipated by the federal interagency Remediation Technology Development Forum.

Contributed by Robert Puls, EPA NRMRL (puls.robert@epa.gov or 580-436-8543), Mitchell Olson, CSU (mitcello@engr.colostate.edu or 970-491-8720), and Tom Sale, Ph.D., CSU (tsale@engr.colostate.eduor 970-491-8413)

ERH Pilot Project Removes 48 Tons of PCA DNAPL Within Six Months

In 2003-2004, the U.S. Navy deployed in-situ three-phase electrical resistance heating (ERH) technology on a pilot scale to evaluate the technology’s success in treating DNAPL at Site 89 of the Marine Corps Base Camp Lejeune, NC. Though high concentrations of 1,1,2,2-tetrachloroethane (PCA) and TCE previously were removed from unsaturated soil using low-temperature thermal desorption, additional treatment was needed to address the separate-phase DNAPL encountered at depths of 5-19 ft bgs. Results from the pilot will be used to evaluate methods of addressing additional areas of DNAPL throughout the site.

Three hydrostratigraphic units comprise the treatment interval of 5-26 ft bgs: fine- to medium-grained sand with interbedded silt and clay layers from grade to about 8-15 ft bgs; a discontinuous layer of clay with fine sand or silt at 8-18 ft bgs; and a lower clay combined with calcareous sand and shell or fossil fragments. Hydraulic conductivity within the interval decreases with depth from 10-3 cm/s to 10-6 cm/s, and the water table is at an average depth of 3 ft bgs.

A network of 15 monitoring wells was established throughout the area to monitor treatment performance and detect any undesired contaminant migration. Seventeen horizontal vapor extraction wells were installed in the area and covered by a unique 10,000-ft² impermeable and thermally insulated cap. Due to the anticipated volume of contaminants and extensive base activity surrounding the site, all collected vapors were treated using a catalytic oxidizer followed by a caustic wet scrubber.

In-situ treatment of the unsaturated zone employed three-phase electricity delivered to an array of 91 electrodes in an area of 15,900 ft². Each electrode was vented and installed with the dual capability of extracting vapors and ground water for hydraulic control in order to mitigate lateral and downward migration of DNAPL into the aquifer.

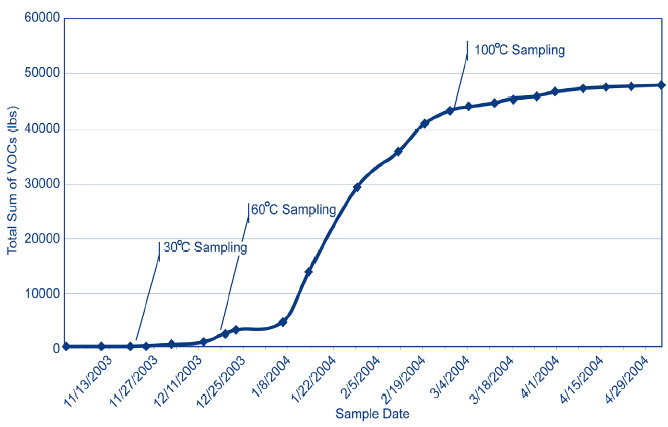

Active heating of the entire treatment area began after a two-month period of gradual heating of the area’s “floor” and “walls.” VOC contaminant recovery was observed immediately after system start-up and continued while temperatures increased. After four months of active heating, subsurface target temperatures of 100°C were reached in both soil and ground water, and substantial contaminant recovery still was occurring (Figure 3).

The system continued to operate another two months, when analytical sampling indicated that the average concentration of PCE had decreased from 992 mg/L to 0.9 mg/L in ground-water samples taken from shallow treatment-area wells. Upon system shutdown, the average concentration of PCA in soil had decreased from 2,351 µg/kg to less than 1 µg/kg. Similarly, concentrations of TCE as a PCE degradation product had decreased from an average of 1,148 µg/kg to less than 1 µg/kg.

Analysis of contaminant concentrations throughout the treatment period indicate that the VOC extraction rate increased from an average of 2 lbs/day upon system startup to 200-440 lbs/day after three months of operation. Removal then began declining to a final rate of approximately 10 lbs/day, at which point ground-water and soil sampling within the treatment area indicated a 99% VOC reduction in both media.

Quantitative sampling of the vacuum system influent determined that more than 48,000 pounds of VOCs were removed as a result of electrical resistance heating, at a calculated cost of $41/lb. Soil and ground-water monitoring detected no air emissions at the project borders or migration of contaminants from the treatment area. Based on these results, the U.S. Navy will consider use of electrical resistance heating to treat additional DNAPL areas at Camp Lejeune.

Contributed by Dan Hood, U.S. Navy (daniel.r.hood@navy.mil or 757-322-4630), Gena Townsend, U.S. EPA Region 4 (townsend.gena@epa.gov or 404-562-8538), and Ron Kenyon, Shaw Group (ronald.kenyon@shawgrp.com or 770-663-1453)

Thermo-Chemical Process Converts Contaminated Sediment to Clean Construction Material

The New Jersey Department of Transportation’s Office of Maritime Resources (NJ DOT/OMR) and U.S. EPA Region 2 recently completed Phase 1 of a full-scale pilot test on the use of an ex-situ thermo-chemical process (Cement-Lock®) for decontamination and beneficial use of dredged sediment from the New York and New Jersey Harbor. The full-scale test has been in design and construction since 2001 as part of ongoing efforts to treat dredged material containing a wide range of harbor contaminants. This phase was designed to:

- Process a bulk quantity of navigational sediment in a technology-specific demonstration plant;

- Demonstrate the mechanical operation and trouble-shooting capability of the plant’s systems;

- Demonstrate the technology’s effectiveness in treating organic and inorganic contaminants;

- Show destruction rather than transference of organic contaminants;

- Determine leachability of the treated sediment;

- Demonstrate the treated material’s qualifications for beneficial use under state regulations, and

- Educate the public on sediment decontamination issues.

The full-scale pilot results demonstrate that the processed sediment meets the state’s residential direct-contact cleanup criteria for soil and is suitable for use as construction fill. The NJ DOT/OMR and EPA Region 2 currently are evaluating recommendations for Phase 2 of the project, which will employ the thermo-chemical process to treat up to 400 yd³ of sediment over a three-week period later this summer.

Phase 1 testing included treatment of approximately 400 yd³ of navigational sediment dredged by the U.S. Army Corps of Engineers from the Stratus Petroleum site in upper Newark Bay, NJ. The sediment was screened to -¾ inches, mechanically dewatered onsite, and then transported to the demonstration facility in Bayonne, NJ. The sediment was blended with mineral modifiers typically used in cement manufacturing and the mixture was auger-screw fed into a natural-gas-fired rotary kiln, where it was heated for one hour at a temperature of 1,835° F. Thermal treatment successfully destroyed complex contaminants such as polychlorinated biphenyls (PCBs), dioxins, and polynuclear aromatic hydrocarbons and converted the mixture into innocuous components. Volatile metals such as mercury were captured in an activated carbon bed.

Decontamination operations using this technology have been conducted in both slagging and non-slagging modes. In slagging mode, the dredged material with added modifiers melts completely during travel through the kiln. Upon exiting the kiln, the melt is quenched with water, and the cooled material takes a non-crystalline form comprising thin, black, glassy strands (“Ecomelt”). The glassy product can be ground into a fine powder and blended with Portland cement to yield construction-grade cement. Independent laboratory testing on the construction-grade cement yielded a compressive strength of 5,190 psi, which exceeds ASTM requirements (3,480 psi) for blended cement. Under non-slagging processing mode, the sediment is converted into a larger-grained aggregate material (“EcoAggMat”) that can be used as clean fill or as partial replacement for sand in mortar.

Over a 17-day period in early 2005, the Bayonne plant processed sediment at a rate of approximately 1,000 lbs/hr, or 0.5 yd³/hr, in non-slagging mode. A total of approximately 80 yd³ of the sediment/modifier mixture was processed, which yielded about 53 tons of the remediated aggregate product. Earlier slagging-mode trials on approximately 20 yd³ of the sediment/modifier mixture produced approximately two tons of the glassy product, with large clinkers or slag accounting for the material balance.

EPA’s Superfund Innovative Technology Evaluation (SITE) Program conducted a broad range of environmental tests to characterize the end products and confirm that organic contaminants were destroyed during thermo-chemical processing at the Bayonne plant. Testing of the aggregate product by the toxicity characteristic leaching procedure (TCLP), synthetic precipitation leaching procedure, and multiple extraction procedure indicated no leaching of metals above the state’s ground-water quality criteria. TCLP tests also detected no priority elements in leachate from the glassy product.

Plant emission rates for semi-volatile organic compounds and target compounds such as PCBs met the state’s air quality permit limits, and 99% of the toxicity equivalency from PCBs, dioxins, and furan congeners in the sediment was destroyed during treatment. Comparison of mercury emission rates against concentrations of mercury entering the plant’s activated carbon bed showed a 99% collection efficiency, which exceeds the state’s air permit requirement of 70% for mercury.

Due to processing difficulties common in plant startups and shakedowns of this type, continuous and sustained operations for processing all of the targeted 400 yd³ proved difficult. Process enhancements will be implemented prior to initiating Phase 2 of the project, with focus on increasing the consistency of sediment feeding, improving the control of sediment and modifiers during treatment, and increasing the rates of slag discharge from the system’s rotary kiln. It is also anticipated that co-processing of contaminated sediment with other materials containing high calorific values, such as petroleum wastes and shredded tires, would reduce fuel costs and improve process economics.

ERRATA

Please note corrections to the article entitled “Tree-Core Analysis Brings Savings to Site Assessments” as published in the November 2005 issue of Technology News and Trends. The U.S. Geological Survey, rather than the U.S. Department of Agriculture, pioneered the tree-coring approach for site assessment. Also, all measurements involving “µg” (microgram) units were printed erroneously as “mg” (milligram) units. The Technology News and Trends editorial staff apologizes for any inconvenience this may have caused.

Based on these results, the NJ Department of Environmental Protection anticipates approval of the Cement-Lock aggregate to be used as clean fill at a South Kearny, NJ, site undergoing remediation. Researchers estimate that sediment processing costs for a large-scale commercial thermo-chemical plant would be similar to those of alternate options for sediment disposal in the harbor, which average $35/yd³.

Contributed by Eric Stern, U.S. EPA Region 2 (stern.eric@epa.gov or 212-637-3806), Scott Douglas, NJ DOT/OMR (scott.douglas@dot.state.nj.us or 609-530-4773), and Michael Mensinger, Gas Technology Institute (mike.mensinger@gastechnology.org or 847-768-0602)