Nanoscale ZVI Injection Rapidly Reduced Source CVOCs in Bedrock Ground Water

CLU-IN Resources

CLU-IN’s "Alternative Landfill Cover Project Profiles" describe more than 80 site-specific demonstrations and full-scale applications of alternative design covers at disposal sites containing solid, hazardous, and/or radioactive wastes. With a focus on evapotranspiration (ET) covers, capillary barrier ET covers, and bioengineering management, the searchable profiles provide information on cover designs, monitoring, and costs. Project managers, technology vendors, and site owners are invited to electronically submit additional project profiles.

Pilot-scale testing at a RCRA-regulated facility in Research Triangle Park (RTP), NC, was conducted in 2002 to test the effectiveness of in-situ injections of nanoscale zero-valent iron (NZVI) in removing chlorinated hydrocarbons from bedrock ground water. Pre- and post-treatment sample analysis indicated a 90% reduction of total chlorinated volatile organic compound (CVOC) concentrations within seven days of the injection. During the following five weeks, concentrations of trichloroethene (TCE), as the primary contaminant of concern, decreased more than 99%.

Ground-water contaminants consist mainly of CVOCs that were released during industrial activities conducted by the former property owners. The pilot test was conducted in an area downgradient from a past waste disposal area with the highest TCE concentrations (14,000 µg/L) and a high hydraulic conductivity (approximately 10-3 cm/s). Ground water is approximately 30 feet below ground surface (bgs) within Triassic-aged interbedded siltstone and sandstone. NZVI technology rather than in-situ chemical oxidation was selected due to the site’s low to moderate oxidation/reduction potential (ORP) and evidence that NZVI would not destroy the native microbial populations. Earlier testing also demonstrated the technology’s capability to increase concentration gradients and contaminant mass transfer from dense nonaqueous phase liquid (DNAPL) to the dissolved phase.

The injection well was installed into shallow bedrock approximately 125 feet from the disposal area, and two downgradient observation wells were drilled in similar subsurface environments approximately 22 feet and 43 feet from the disposal area. An existing monitoring well located 63 feet downgradient served as a third monitoring point. NZVI was injected into ground water as a slurry suspension prepared onsite using potable water and bi-metallic (palladium-doped) nanoscale particles (BNPs) ranging in size from 1 to 100 nm. A total slurry volume of 1,600 gallons, at a BNP concentration of 1.9 g/L, was injected into the subsurface over two days. Electronic monitoring was conducted continuously during the NZVI injection to ensure a flow rate averaging 0.6 gpm.

Ground-water quality was monitored before and after the injection to evaluate changes in CVOC concentrations, ORP, dissolved oxygen, pH, specific conductance, and temperature. In addition to a 90% reduction in total CVOCs in the injection well and the nearest observation well within the first week, TCE concentrations decreased from 14,000 µg/L to below the 2.8 µg/L cleanup target (specified by State ground-water standards) within six weeks (Figure 1). Concentrations of 1,2-dichloroethane, benzene, toluene, ethylbenzene, and xylenes also declined significantly, by over 50% within 2-3 months.

Prior to treatment, the test area exhibited primarily moderate oxidative conditions with an ORP of +50mV to -100 mV. The injection created highly reducing methanogenic conditions with an ORP of -700 mV in the injection well and -450V in the nearest monitoring well. These lower ORPs persisted for a minimum of 28 weeks in the injection well and the two closest observation wells. Monitoring for potential mobilization of ORP-sensitive metals such as manganese, barium, and arsenic identified no concentration increases in the test area.

Measurements of VOC concentrations indicated a 20- to 40-foot radius of influence around the injection well. Samples collected at the beginning and end of the purge cycle indicated that treatment distribution was relatively uniform within 20 feet of the injection well but more heterogeneous at greater distances. Microbiological testing of ground-water samples from the monitoring wells indicated that BNP injection had no detrimental effect on the total biomass and community structure at the injection well, suggesting that bioremediation may serve as a final cleanup step.

Reactivity of the NZVI particles was exhausted and contaminant rebound was observed after three months. Extension of the effective particle lifetime could be achieved by conducting repeat injections under the lower ORP conditions already established by an initial injection. Design of a full-scale NZVI system for the RTP site is underway, with anticipated startup in 2006. Remediation of the TCE plume will be further evaluated following these source control efforts.

Contributed by Rob McDaniel, NC Department of Environment and Natural Resources (919-733-2178 or robert.mcdaniel@ncmail.net), Lindsey Walata, GlaxoSmithKline, Wei-xian Zhang, Ph.D., Lehigh University (610-758-5318 or wez3@lehigh.edu), and Florin Gheorghiu, Golder Associates, Inc. (856-616-8166 or florin@golder.com)

Deep PRB Installed by Vertical Hydrofracturing Demonstrates Long-Term Success

A 240-foot continuous permeable reactive barrier (PRB) was constructed in 1999 at the former Toastmaster Superfund site in Centerville, IA, to remediate ground water containing concentrations of TCE and cis-1,2-dichloroethene (DCE) reaching 810,000 µg/L and 1,000 µg/L, respectively. Vertical hydrofracturing was used to inject 115 tons of zero-valent iron filings extending from 25 to 75 feet bgs, a depth often limiting the use of a trenched PRB. Monitoring results collected over the past five years show an average contaminant reduction of up to 99.7% in ground water exiting the barrier.

The site formerly was used for electrical appliance manufacturing processes involving the use of TCE-based solvents. Field investigations in 1988 revealed TCE concentrations of 14,000 µg/L in ground water near the source area, which led to the selection of a pump-and-treat remedy. The ROD later was amended for use of an in-situ PRB for ground-water remediation, a fracture-enhanced dual phase soil vapor extraction (SVE) system for source removal in the vadose zone, and monitored natural attenuation for the residual downgradient plume.

Site ground water is approximately 30 feet bgs with an estimated flow rate of 0.4 ft/day. The aquifer consists of medium- to fine-grained, loose-flowing, channel sands between layers of over-consolidated, stiff to very stiff till. Hydraulic pulse interference tests (HPITs) showed the average hydraulic conductivity of the aquifer to range from 0.4 to 115 ft/day. These conditions were optimal for the medium sand-size PRB iron filings, which have a hydraulic conductivity of approximately 150 ft/day and a porosity of about 55%. This is double the porosity of the majority of the surrounding soils, hence, the average residence time of contaminated ground water in the PRB is doubled.

The PRB was installed 10 feet downgradient of a building directly above the contaminant source area (Figure 2). Installation of the PRB involved drilling sixteen 6-inch boreholes at 15-foot intervals and depths ranging from 45 to 75 ft bgs. The PRB was constructed from the “bottom up” by placing packers to isolate the target frac casing, which was used to propagate the fracture and inject iron filings. This formed panels approximately 20 feet high by 15 feet wide. Due to relatively slow ground-water movement and the higher porosity of the iron filings, a PRB thickness of only 3 inches was considered necessary.

The iron filings were mixed with a hydroxypropylguar biodegradable gel containing a cross-linking agent and enzyme. The mixture was injected at low pressure (5 psi higher than the surrounding horizontal stress at depth) directly into the aquifer through the downhole frac casing systems. Each gallon of gel contained approximately 10 pounds of iron filings. The cross-linking agent immediately caused the gel to become highly viscous, with the strength to carry iron filings to their designed destinations. Within hours of injection, the enzyme broke the gel into water and non-toxic sugars to leave a continuous coalesced wall of permeable iron filings between neighboring frac casings.

Use of a “trenchless” PRB construction technique required a suite of QA/QC tools:

- bench-scale column tests to determine primary and secondary contaminants, daughter products, and respective half-lives;

- pre-construction HPITs to determine hydraulic conductivity and to establish benchmarks for post-construction comparisons;

- probabalistic design involving integration of column test data, HPIT results, a multi-species VOC model for degradation within the PRB, and a fate and transport model for downgradient natural attenuation;

- active resistivity imaging to monitor PRB construction; and

- post-construction inclined profile sampling to verify PRB thickness.

The PRB influent and effluent were analyzed quarterly over the first four years and semi-annually thereafter. Due to the low ground-water flow velocities, downgradient monitoring wells were not expected to experience significant reductions in VOC concentrations for three years. However, the analytical results indicate that TCE and cis-1,2-DCE concentrations decreased to near non-detect levels within 2½ years. Results indicate that TCE concentrations have decreased from 810,000 µg/L to an average of 27 µg/L and cis-1,2-DCE concentrations have decreased from 1,000 µg/L to an average of 160 µg/L.

No signs of iron reactivity loss or PRB fouling have been observed. Recent infiltration of surface water seeping from a pile of road salt into one of the downgradient monitoring wells, as evidenced by unusually high sodium and nitrate levels, may have caused minor increases in VOC concentrations. Following replacement of the monitoring well, VOC concentrations appear to be decreasing.

Use of the PRB is anticipated to achieve ground-water cleanup in 2009, 10 years after placement. Design and construction of the PRB was estimated to cost $938,000. The vertical hydraulic fracturing technique has since been used to install PRBs extending to greater depths ranging from 95 to 115 feet at four other sites, including Tinker Air Force Base, Sierra Army Depot, and two commercial sites in California.

Contributed by John Cook, EPA Region 7 (913-551-7716 or cook.john@epa.gov) and Grant Hocking and Jim Ortman, GeoSierra (678-514-3300 or ghocking@geosierra.com and jortman@geosierra.com)

Mass Flux Evaluation Finds SEAR Continues to Reduce Contaminant Plume

Measurements of contaminant mass flux at Hill Air Force Base Operable Unit 2 (OU2) show that aggressive source zone remediation using surfactant-enhanced aquifer remediation (SEAR) technology has resulted in a 67-90% decrease in mass flux from the contaminant source zone. Under the Strategic Environmental Research and Development Program (SERDP), researchers from the U.S. EPA Robert S. Kerr Environmental Research Center and University of Florida conducted two rounds of post-treatment measurements following the 2002 SEAR treatment. An updated site conceptual model and contaminant fate and transport modeling suggest that flux from the source zone now is less than the assimilative capacity of the aquifer. Over time, decreases in the areal extent of the dissolved plume and the lifetime of the contaminant source are expected to occur.

SEAR at OU2 was designed to generate and propagate in-situ foam to divert surfactant from the upper, uncontaminated portion of the aquifer into the lower DNAPL-contaminated zone. To generate the foam, air was injected with surfactant in a two-hour alternating mode. The 21-day SEAR process consisted of three days of pre-surfactant brine flooding using a 1.0 wt% sodium chloride (NaCl) solution; seven days of surfactant flooding with 4.0 wt% sodium dihexyl sulfosuccinate (MA-80I) and 1.0 wt% NaCl; and 11 days of post-surfactant brine/water flooding. Surfactant/foam flooding resulted in recovery of approximately 220 gallons of DNAPL.

Mass flux was measured immediately downgradient of an area of DNAPL contamination outside a bentonite-slurry containment wall that surrounds most of the OU2 source zone. Pre-treatment ground-water contaminant concentrations in the flux monitoring wells ranged from 9 to 150 mg/L. Following SEAR application, only one confirmation soil sample exhibited residual DNAPL in the source zone, with a saturation of 2%. No mobile or pooled DNAPL has been observed since SEAR treatment, and contaminant concentrations in ground-water samples collected from and immediately downgradient of the treatment zone have decreased by 1-2 orders of magnitude.

Monitoring of cumulative flux rather than contaminant concentrations is allowing for direct evaluation of the contaminant mass loading rate and improved decision-making regarding remedial efforts at OU2. Two distinct approaches–a static “flux meter” technique and a dynamic integral pumping test–were used to assess contaminant flux immediately prior to SEAR implementation and in two post-treatment measurement rounds. Both techniques use forms of point measurements and derive mass flux based on spatial integration of the product of local flux-averaged contaminant concentration and water flux.

TCE mass flux from the source zone prior to treatment was estimated to be 107 g/day based on data collected using the flux meter technique, with flux values integrated over the control plane to produce a mass loading rate. Approximately 10 months after source zone treatment, a flux of 10 g/day was estimated. Similar results were obtained with the integral pumping technique. Initial mass flux estimates ranged from 52 to 115 g/day, compared to 17 to 29 g/day after remediation. Data reduction for the most recent (2004) flux measurements is not yet complete but preliminary results suggest that the contaminant flux is similar to that measured the previous year, with no evidence of contaminant rebound. Measurements reflect significant reductions in mass flux at each of the eight monitoring wells used for data collection (Figure 3).

Prior to SEAR implementation, concentrations of cis-1,2-DCE were below quantification limits. In post-SEAR flux measurements, however, cis-1,2-DCE contributed 30-35% of the total mass flux. These data suggest that application of SEAR remedial fluids stimulated transformation of residual TCE to cis-DCE due to anaerobic reductive dechlorination.

Results also suggest that the MA-80I surfactant has provided the carbon donor necessary to stimulate continued reductive dechlorination. An apparent degradation product of the MA-80I, methyl isobutyl ketone (MIBK), was detected last year at relatively high concentrations (up to 409 mg/L) in the source zone. Continued monitoring of MIBK concentration indicates that it is rapidly degrading, with recent measurements in the source zone showing maximum concentrations of approximately 60 mg/L. An additional round of measurements using both of the mass flux assessment techniques is anticipated.

Contributed by Kyle Gorder, Hill Air Force Base (801-775-2559 or kyle.gorder@hill.af.mil), Michael Brooks, U.S. EPA/Robert S. Kerr Environmental Research Center (580-436-8982 or brooks.michael@epa.gov), and Chuck Holbert, URS Corporation (801-904-4056 or chuck_holbert@urscorp.com)

EPA Recommends a New Approach for Accelerating Landfill Biodegradation

EPA began working with Waste Management Inc. under a cooperative research and development agreement in 2000 to examine various methods for improving landfill efficiencies. Related studies underway at the Outer Loop Recycling and Disposal Facility in Louisville, KY, involve two types of bioreactor-based technology. The Agency anticipates that bioreactors will enhance waste containment in unlined landfills and could accelerate microbial degradation of hazardous and solid waste contaminants by 50%. Accordingly, in March 2004 EPA began allowing states to issue research, development, and demonstration permits to large-scale landfill operations for innovative methods such as bioreactors.

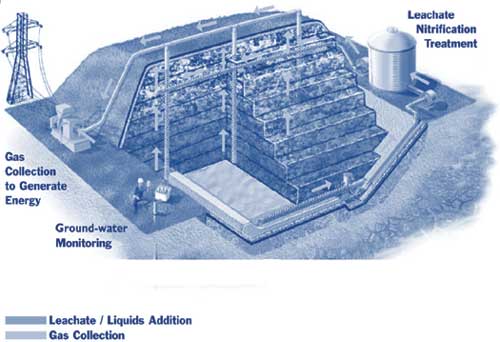

By recirculating landfill leachate through existing waste material and trenches constructed outside the waste perimeter, bioreactors are designed to increase landfill moisture. This approach contrasts significantly with previously recommended and commonly used “dry tomb” methods relying on reduction of landfill moisture content.

One of the two bioreactors under evaluation involves only anaerobic mechanisms, while the second operates under both anaerobic and aerobic conditions. Although anaerobic conditions naturally occur in most landfills, optimum degradation of solid waste or CERCLA contaminants requires the addition of moisture. This type of bioreactor conceptually lends itself to retrofitting of existing landfills (Figure 4). In contrast, an aerobic-anaerobic “hybrid” bioreactor landfill is designed to cause rapid biodegradation of easily degradable waste in the aerobic stage, thus reducing the production of organic acids in the anaerobic stage and generating earlier onset of methanogenesis.

Both types of bioreactor landfills offer advantages over dry tomb landfills:

- The accelerated degradation of waste mass can increase settlement, providing additional years of landfilling capacity.

- The increased rate of methane generation caused by biological activity allows for more effective landfill gas control and lower costs for onsite electrical generation.

- Recirculation of leachate lowers the costs for leachate management.

- Controlled but accelerated degradation of the waste reduces post-closure care and future exposure risk.

ERRATA

In the January 2005 Technology News and Trends article, "Ultraviolet and Hydrogen Peroxide Treatment Removes 1,4-Dioxane from Multiple Aquifers," measurement units for the State of Michigan drinking water standards on 1,4-dioxane and bromate were printed erroneously. The correct standards are 85 µg/L for 1,4-dioxane and 10 µg/L for bromate. It also should be noted that maximum 1,4-dioxane concentrations in the treated plume, as described, are now less than 10,000 µg/L.

The Agency currently is seeking sites at which to demonstrate anaerobic retrofitting of an existing landfill or construction of a hybrid bioreactor facility. Under EPA’s Project XL, landfill pilot projects employing bioreactors are underway in Buncombe County, VA, King George County, VA, and Yolo County, CA [see March 2003 issue of Technology News and Trends for more information]. In addition to bioreactor technology, the Agency is evaluating the use of compost as a landfill cover at the Outer Loop facility.

Thabet Tolaymat, Ph.D, National Risk Management Research Laboratory (513-487-2860 or tolaymat.thabet@epa.gov)