- Hydraulic Conductivity Loss at the Monticello PRB Leads to Trial Use of Ex-Situ Treatment Cell

- Resources on Mining Technologies

- Compost-Free Bioreactors Remove Metals from Acid Rock Drainage

- Evaluation of Mining Technologies Needs Standardized Performance-Based Measures

- PRB Containing Processed Fish Bones Sequesters Metals from Ground Water

- MWTP Demonstrates Integrated Passive Biological System for Treating Acid Rock Drainage

This issue of Technology News and Trends highlights innovative technologies used to treat contaminants affecting soil, ground water, and surface water at mining sites. In addition to complex problems associated with acid rock drainage (ARD), these sites typically involve remote locations, limited access, extreme climates, a predominance of heavy metal contaminants, and large volumes of contaminated tailings. The U.S. EPA is working with other federal and state agencies, academia, and private industry to demonstrate innovative technologies and associated performance measures for use at these sites.

Hydraulic Conductivity Loss at the Monticello PRB Leads to Trial Use of Ex-Situ Treatment Cell

Mine Waste Technology Program (MWTP)

As a joint program sponsored by the U.S. DOE and U.S. EPA, the MWTP works with academic organizations and private industry to conduct pilot-scale demonstrations and technology transfer related to mine waste issues. Project summaries, solicitations, and networking opportunities are available online at http://www.epa.gov/

minewastetechnology.

Performance monitoring of the permeable reactive barrier (PRB) that has operated since 1999 at a former mining/milling site near Monticello, UT, recently revealed significant reductions in the system’s ability to treat contaminated ground water. The PRB had successfully reduced high concentrations of target radioactive and metal contaminants to non-detectable levels during the first four years of operation [see June 2000 Ground Water Currents and July 2003 Technology News and Trends online at http://www.cluin.org]. During the past two years, however, hydraulic conductivity throughout the treatment area decreased and caused ground water to mound upgradient of the PRB. The U.S. Department of Energy (DOE) and U.S. EPA subsequently investigated the system’s reduced performance and identified a supplemental remedy for ground-water treatment.

The original 100-ft-wide by 6-ft-thick PRB was designed to treat ground water containing uranium, selenium, vanadium, and other contaminants with concentrations exceeding maximum contaminant levels (MCLs) by as much as a factor of 100. The PRB was constructed with a 2-ft-thick upgradient zone containing 13% (by volume) zero-valent iron (ZVI) mixed with pea gravel and a 4-ft-thick downgradient zone containing 100% ZVI. Though contaminant concentrations in ground water exiting the PRB remain below MCLs after seven years of operation, hydraulic conductivity in the downgradient ZVI zone has decreased by nearly three orders of magnitude.

In February 2002, after 30 months of PRB operation, 70 cores were collected from the reactive media. Analytical results of 279 random samples indicated that more than 8,000 kg of calcium carbonate and 24 kg of uranium- and vanadium-bearing minerals had deposited in the PRB. Nearly all the uranium and vanadium precipitated in the upgradient gravel/ZVI zone; however, calcium was found throughout both the gravel/ZVI and ZVI zones, indicating that precipitation rates of calcium carbonate require longer residence times than uranium and vanadium. Solid-phase chemistry data were used in combination with dissolved-phase ground-water chemistry to estimate an average ground-water flow rate of 6-9 gpm.

Results of a second round of coring 18 months later, in August 2003, indicated that uranium and calcium continued to precipitate in the PRB. On the basis of the increased concentrations of uranium and calcium since the first coring, ground-water flux through the PRB was estimated to consistently average approximately 5 gpm. Electron microprobe analysis of the core samples indicated that ZVI grains in the upgradient gravel/ZVI zone had corroded but that much of the original ZVI mass remained. Mixtures of iron oxides and carbonates had replaced and coated the ZVI grains and/or crystallized in interstitial space.

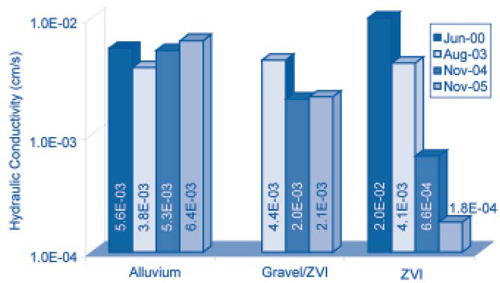

To evaluate trends in hydraulic conductivity, gas-injection slug tests were conducted in June 2000, August 2003, November 2004, and November 2005. The number of wells tested in each event varied from 30 to 45. Tests revealed that hydraulic conductivity values had remained nearly constant within the upgradient alluvium and the gravel/ZVI zone but decreased 3 orders of magnitude in some wells within the ZVI zone during this period (averages shown in Figure 1).

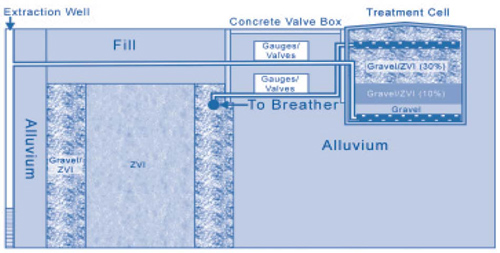

After 44 months of PRB operation, upgradient ground-water mounding had advanced to approximately 1 foot of ground surface. As a result, an extraction well immediately upgradient of the PRB (within the area of mounded ground water) and a supplemental ex-situ treatment cell were installed last June to help alleviate the mounding and ensure continued treatment of ground water. The treatment cell consists of a 6-ft-diameter by 5-ft-deep concrete cylinder located immediately downgradient of the existing PRB.

On the basis of earlier site-specific tests showing enhanced longevity of a gravel/ZVI mixture over ZVI alone, the cell’s reactive medium consists of 2 tons of ZVI mixed with pea gravel (Figure 2). Contaminated ground water is pumped into the bottom of the treatment cell and allowed to flow up through the reactive media at a typical flux of 4-5 gpm. Real-time measurements of influent pressure, flow rates, ground-water levels, and pH of the system are recorded every 5 minutes and transmitted to the DOE Office of Legacy Management in Grand Junction, CO, for evaluation.

Ground-water levels upgradient of the PRB decreased from nearly ground surface to 5 feet below ground surface (bgs) within five months of treatment cell operation, and hydraulic conductivity of the treatment cell has not changed since the cell installation. Analysis of weekly and monthly ground-water samples indicates that uranium concentrations entering the system range from 100 to 250 µg/L and that effluent water is meeting State of Utah ground-water standards for uranium (less than 45 µg/L). Concentrations of selenium currently decrease from 25 µg/L in the cell influent to 0.7 µg/L in the effluent.

The site ground-water flow model predicts that the contaminant plume will move downgradient of the PRB by 2015. Due to the PRB’s current function as a physical barrier, its use will continue for source control and to provide a mound of ground water to feed the treatment cell. PRB coring will be conducted this spring to observe mineralization that now causes nearly complete blockage of ground-water flow. High concentrations of dissolved salts in the ground water are partially responsible for the mineralization in the ZVI zone, which causes the reduction in hydraulic conductivity and imminent failure of the PRB. Although design-phase treatability studies had indicated the potential for mineral precipitation, the use of gravel-dominated media in the upgradient zone was expected to increase the likelihood that the PRB would function for the 10-15 years needed to flush contaminants from the aquifer.

Long-term results indicate that the PRB effectively treated ground water for approximately four years. Limited data from operation of the supplemental treatment cell indicate that the system may be capable of treating contaminated ground-water flux to an extent similar to the PRB’s. The treatment cell has treated 700,000 gallons of contaminated ground water during its first six months of operation, while the PRB treated approximately 8.2 million gallons of water during its six years of operation.

Cost analysis indicates that treatment cell construction was completed for approximately $50,000 versus more than $1million for PRB construction. To achieve a comparable level of confidence, performance monitoring also will cost significantly less for the treatment cell than for the PRB. In addition, treatment cell decommissioning costs are estimated at less than $5,000 while PRB decommissioning costs are estimated at more than $50,000.

Due to the hydrogeological conditions and economics, the U.S. DOE and EPA will consider replacing the ZVI reactive media in the treatment cell (for less than $2,000) when the cell no longer adequately treats the contaminants of concern (uranium and vanadium) or when hydraulic conductivity in the cell decreases and causes mounding upgradient of the PRB. Replacement of reactive material in the PRB gate, which would cost approximately $700,000, is not considered a viable alternative.

Paul Mushovic U.S. EPA Region 8 (mushovic.paul@epa.gov or 303-312-6662), Tim Bartlett, S.M. Stoller Corp. (tim.bartlett@gjo.doe.gov or 970-248-7741), and Stan Morrison, Ph.D., S.M. Stoller Corp. (stan.morrison@gjo.doe.gov or 970-248-6373)

Resources on Mining Technologies

- Abandoned Mine Lands (AML) Web Page: This on-line resource (http://www.epa.gov/aml) is updated by the U.S. EPA regularly in order to provide a comprehensive source of AML information such as federal and state policies, technical guidance, and site inventories.

- Hard Rock 2006–Sustainable Modern Mining Applications: The U.S. EPA Office of Research and Development (ORD)/NRMRL will hold this conference on November 14-16, 2006, in Tucson, AZ, to discuss sustainable opportunities for extraction and utilization of mining resources. Conference abstracts are due April 7, 2006. More information is available on the AML web page.

- Jump-Starting Ecosystem Restoration–Beyond Hydro-Seeding: The U.S. EPA Land Revitalization Office and Technology Innovation and Field Services Division offer this new series of Internet seminars as an opportunity to learn about the role of ecological restoration in the cleanup of sites, including mining sites; the relationship among land disturbance, functioning ecological systems, and restoration project management; and techniques for implementing ecosystem restoration. Upcoming training schedules and archived seminars are available on CLU-IN (http://www.cluin.org/training).

- Copper Basin Mining District–Case Study: This publication describes joint efforts among the U.S. EPA, the State of Tennessee, and private industry to clean, reforest, and stabilize lands affected by extensive ore processing in the Copper Basin Mining District, TN. The case study can be downloaded from the AML web page.

Compost-Free Bioreactors Remove Metals from Acid Rock Drainage

The U.S. EPA’s National Risk Management Research Laboratory (NRMRL) recently completed a two-year evaluation of a full-scale, compost-free bioreactor system operating at the Leviathan Mine Superfund site in northeastern California. The technology uses a liquid-carbon source in a rock matrix, rather than compost or wood chips, which is consumed by bacteria and collapses over time. Preliminary performance tests (reported in the May 2004 issue of Technology News and Trends) indicated 91-99% efficiency in removal of target metals from ARD. Performance results over the past two years confirmed that the system achieved a target-metal removal efficiency of 95%.

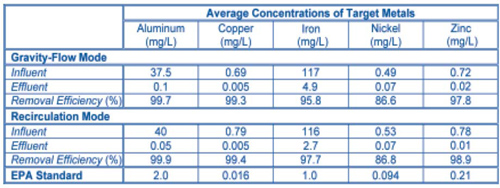

The treatment system consists of two bioreactors, two settling ponds, and an aeration channel. It treats up to 30 gpm of ARD year-round in either gravity-flow or recirculation mode. Operation in gravity-flow mode causes metals to precipitate in both the bioreactors and settling pond, which requires frequent flushing and disturbs bacteria in the bioreactors. In recirculation mode, metals precipitate in the settling pond, and the pond effluent is recirculated through the bioreactors, thereby reducing the need for bioreactor flushing. Overall, the recirculation mode places less stress on the bacteria, reduces sodium hydroxide consumption, and improves handling of solids.

Thirteen sampling events were conducted between November 2003 and July 2005. During each sampling event, NRMRL collected metals data from the system influent and effluent and from flows between the five system components; calculated reductions in metals, sulfate, and acidity between the components; and measured the system’s operating parameters. Final evaluations of the system were based on removal efficiencies for target metals, the ability of effluent concentrations to meet EPA discharge standards, and the characteristics (including disposal requirements) of end-product solid wastes.

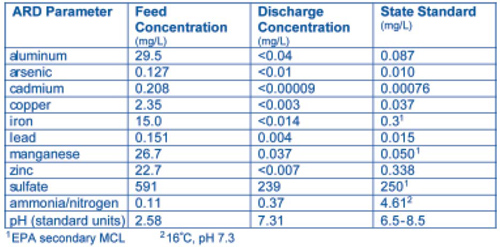

Results indicate that the system reduced concentrations of sulfate ion in the ARD more than 17%, and increased ARD pH from approximately 3.0 to 7.0. Treatment effectively reduced concentrations of all target metals (excluding iron) in the ARD to below EPA interim discharge standards, achieving an average removal efficiency of 95% (Table 1). Iron concentrations met the discharge standards when base addition was optimized. Solids generated by ARD treatment were determined to be non-hazardous under state and federal solid waste regulations. Over the 20 months of operation, the system generated a total of 17 yd³ of dewatered sludge (80% moisture) per million gallons of ARD treated.

The system treated 2.44 million gallons of ARD in gravity-flow mode during the first six months of the study, using 2,440 gallons of sodium hydroxide (in 25% solution) and 1,180 gallons of ethanol. The average removal efficiency exceeded 94% over six sampling events. During the following 14 months, the system operated in a recirculation mode and treated 5.81 million gallons of ARD, using approximately 5,820 gallons of sodium hydroxide and 2,805 gallons of ethanol. Removal efficiency in this mode exceeded 96% over seven sampling events. No difference in sulfate removal efficiencies was found between the two operational modes.

Capital costs for construction of the system were approximately $836,600 for gravity-flow operations and $864,100 for recirculation operations. Based on an average ARD flow rate of 9.45 gpm, operation and maintenance costs during these research activities were $19.45 per 1,000 gallons of treated ARD.

NRMRL determined that compost-free bioreactors provide a constant source of readily oxidized ethanol and effective control of biological population dynamics. Rock substrate bioreactors also offer the advantage of being non-compressible, which stabilizes hydraulic conductivity, enhances precipitate flushing, and avoids short-circuiting of untreated ARD through the bioreactor.

The technology was limited more by weather conditions than operational issues. Though slower biological activity decreased the rate of sulfate reduction during the winter, effluent discharge standards were met year-round. Winter snow pack limited access to this remote site, requiring consumable materials such as sodium hydroxide, ethanol, and diesel fuel to be transported to the site and stored in bulk during the summer. Similarly, equipment replacement, sludge dewatering, and sludge transfer needed to be performed during the summer months. The system required routine maintenance once each week, considerably less than alternative ARD remedies such as lime treatment.

The study determined that successful full-scale implementation of this technology relies on adequate space for the system components, staging areas, and support facilities. Application at the Leviathan Mine required approximately 0.75 acre. The system required less than 0.6 kilowatt hour (KW) of electricity for continuous operation in the recirculation mode. In gravity-flow mode, it required less than 0.1 KW of energy that was supplied by a solar panel and storage batteries.

Based on these results, the bioreactor system will continue in recirculation mode to treat ARD at the Leviathan Mine. The system is continually optimized to reduce the quantity of alcohol and caustic chemicals needed in the treatment process. System enhancements during 2006 will include development of alternate power sources for the recirculation pumps, installation of redundant recirculation pumps to be available in the event of pump failure, and additional protection of the ARD recirculation lines by relocating them below grade. A comprehensive innovative technology report will be available later this summer through EPA’s Superfund Innovative Technology Evaluation Program (online at http://www.epa.gov/ORD/SITE/).

NRMRL anticipates that pilot-scale testing, which typically is required for bioreactors employing compost and wood chip matrices, is unnecessary for this technology at other ARD-impacted sites because uncertainties related to carbon availability, sulfate reduction efficiency, matrix compaction, and solids flushing are essentially eliminated. Instead, bench-scale tests can be used to optimize the ethanol dose necessary for sulfate reduction, to optimize the base type and dose required for acid neutralization, and to determine the volume of metal sulfide precipitate that will be generated by the treatment process.

Contributed by Edward Bates, NRMRL (bates.edward@epa.gov or 513-569-7774), Dr. Tim Tsukamoto, University of Nevada-Reno (timothyt@unr.edu), Glenn Miller, Ph.D., University of Nevada-Reno (gcmiller@unr.edu), and Matt Udell, Tetra Tech EM Inc. (matt.udell@ttemi.com or 916-853-4516)

Evaluation of Mining Technologies Needs Standardized Performance-Based Measures

The U.S. EPA laboratories and program offices continue to evaluate methods for determining the adequacy of site remediation. As part of this effort, EPA’s Environmental Response Team Center (ERTC) evaluated performance-based measures that are needed for demonstrating reductions in mobility and bioavailability of contaminants (particularly metals) in soil. The evaluation identified a range of physical/chemical, biological, and health risk-based tests as well as their advantages and limitations. Although test protocols for some of these technical performance measures (TPMs) are not fully standardized, all of the methods use statistically designed sampling plans and interpretations based on site-specific data.

The study highlights bioavailability concerns commonly encountered during evaluation of remediation technology at hard-rock mining sites, particularly those employing organic soil amendments such as biosolids. In-situ biosolid technology involves introducing organic materials such as compost, manure, wood chips, or wood ash and nonorganic material such as lime to establish surface-soil structure and conditions amenable to plant growth. These materials are incorporated directly into contaminated soil or placed on top of the soil, which facilitates contaminant immobilization by chemical/biological processes such as adsorption. Iron and magnesium oxide concentrations, as well as the organic matter itself, render the biosolids particularly amenable to cadmium, lead, and zinc immobilization. Application of this in-situ technology does not reduce the concentrations of contaminants but it will reduce their bioavailability, mobility, and leachability. Typical regulatory tests determining total concentrations of contaminants do not illustrate the technology effectiveness. As a result, a broad suite of TPMs is needed to evaluate the ability of a technology to meet remediation goals involving contaminant mobility and/or toxicity reductions.

Physical/chemical extraction techniques identified during the ERTC evaluation include:

- Pore-water measurement obtained by analyzing contaminant concentrations in soil solution, which offers an absolute measurement of contaminant solubility.

- Sequential extraction that quantifies metal distributions in different solid phases of soil, allowing pre-remediation and post-remediation comparisons to be made.

Biological-based techniques include:

- Gastrointestinal absorption procedures for measuring contaminant uptake in human colon cells through the study of membrane transport mechanisms and associated contaminant interactions.

- Mineralization and assimilation assays employing microbial mineralization and related carbon dioxide evolution to compare contaminant-free controls against soil/slurry solutions containing hydrophobic organic compounds.

- Plant bioassays involving analysis of plant tissue to determine if contaminants are present at elevated or potentially toxic levels, with the capability to measure bioavailability of a wide range of organic and inorganic compounds.

- Earthworm assays involving tests on survival, reproduction, growth, or contamination bioaccumulation of earthworms, which serve as important indicators of contaminant bioavailability in soil due to direct dermal contact.

Health risk-based techniques include:

- Physiological-based extraction test (PBET) testing, an in-vitro test network using grastrointestinal tract parameters representative of a human to predict bioavailability of metals from contaminated soil.

- In-vitro extraction test, a simplified PBET using an aqueous solution to simulate gastrointestinal fluid into which contaminated soil is introduced.

ERTC worked with field staff to demonstrate use of these TPM’s for evaluating organic-amendment technology at mining sites in Leadville, CO, Jasper, MO, Kellogg, ID, Picher, OK, and Prescott, AZ. Although regulatory concurrence on technology effectiveness varies, consistent application of TPMs allows for efficiency comparisons across similar technologies involving similar costs. EPA is working with other organizations such as the Interstate Technology and Regulatory Council to establish cost-effective and consistent protocols for using these TPMs.

Contributed by Harry Compton, U.S. EPA ERTC (compton.harry@epa.gov or 732-321-6751), Mark Sprenger, U.S. EPA ERTC (sprenger.mark@epa.gov or 732-906-6826), and Scott Fredericks, U.S. EPA Office of Solid Waste and Emergency Response (fredericks.scott@epa.gov or 703-603-8771)

PRB Containing Processed Fish Bones Sequesters Metals from Ground Water

Over the past decade, the U.S. Department of Defense, U.S. EPA, and other government or academic agencies sponsored demonstrations employing biogenic apatite as a reactive agent for remediation of soil and ground water. Early applications involved circulating pumped ground water into treatment tanks containing processed fish bones (known as Apatite II™) or the direct mixing of apatite into soil (see the March 2002 issue of Tech Trends, online at http://www.cluin.org/products/newsltrs/ttrend/archive.cfm). More recently, apatite served as the reactive medium in a PRB demonstration at the Success Mine and Mill site in northern Idaho. Evaluation of the system’s performance over four years indicates that the PRB reduced concentrations of target metals in ground water 99%, significantly above the anticipated 75% reduction, but experienced difficulty maintaining a constant flow of water.

The PRB was installed in 2001 to address leaching of metals from approximately 500,000 tons of mine tailings at a former disposal area adjacent to a tributary of the Coeur d’Alene River. Below the tailings, an alluvial layer extends to bedrock at 16-20 feet bgs. Investigations indicated that soil contained lead, zinc, and cadmium in concentrations ranging from 1,000 to 4,000 mg/kg. Ground-water and surface seeps also contained elevated concentrations of the metal leachates, reaching 1.25 mg/L for cadmium, 1.44 mg/L for lead, and 177.0 mg/L for zinc.

Biogenic apatite was selected as the reactive medium due to its ability to stabilize metals in water through precipitation, co-precipitation, sorption, or biological stimulation. In addition, the organic carbon in apatite could serve as both an electron donor and carbon source for sulfate-reducing bacteria that accelerate precipitation of metal (particularly zinc) sulfides directly onto the reactive medium surface. Based on the results of bench-scale tests performed by the Idaho Department of Environmental Quality (IDEQ), fish-bone apatite was selected for the PRB rather than alternate forms such as synthetic hydroxyapatite, mineral apatite from phosphate rock, or cow bones.

Construction of the PRB involved excavation of a 15-ft-wide trench extending 14 feet bgs and 50-ft-long and between the tailings pile and creek. The trench was lined with type-V Portland cement in a baffled pattern to create a two-cell vault that would uniformly receive seep and alluvial ground-water flow. Each cell contains five 6-ft-wide, 9-ft-long chambers separated by plywood baffles that bring ARD into optimal contact with the reactive medium. Both cells were filled with 100% Apatite II.

The vault was plumbed and valved to allow sampling and potential replacement of the reactive media. A 1,200-ft grouted containment wall and hydraulic drain were installed upgradient of the PRB to divert water to the treatment vault while reducing migration of any contaminants bypassing the system. Captured ARD flows from the drain through underground piping and into the vault, where the water is split and piped into each of the two cells for parallel treatment. Upon exiting the vault, treated water discharges to a rock apron that routes it into the nearby creek. Water passes through the vault at a rate of approximately 5 gpm, resulting in a total residence time of approximately 24 hours.

After a year of operation, one of the cells exhibited plugging. A 1:1 mixture of pea gravel and apatite was mixed into the cell to increase porosity and the rate of treatment flow. Data collected over four years of monitoring indicate that water exiting the PRB contains lead and cadmium in average concentrations below the detection limits of 0.005 mg/L and 0.002 mg/L, respectively. Zinc concentrations also decrease as a result of treatment, to below the average background level of 0.100 mg/L. Concentrations of these metals in the effluent consistently meet the State of Idaho criteria for drinking water. In addition, pH of the water increases from 4.5 before treatment to 6.5-7.0 upon exiting the PRB. Slightly elevated concentrations (approximately 10 ppm) of chemical byproducts such as ammonia and phosphate exist in water exiting the vault but decrease after passing through the rock apron.

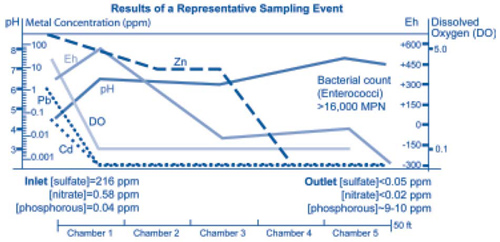

Sample analysis also shows that water entering the vault contains an average sulfate concentration of 250 mg/L, while sulfate in water exiting the system ranges from 35 to 150 mg/L. X-ray diffraction analysis performed by Idaho National Laboratory (INL) confirmed high concentrations of sulfate in precipitates formed in the media. Detailed analyses of microbial communities within the PRB suggest that sulfate-reducing Enterococci bacteria are the primary drivers of sulfate reduction in the ARD. Analysis of the treated water indicates that these microbial populations do not exist in the system effluent. Changes in key ground-water parameters indicate that a corresponding increase in metal precipitation is caused by the sulfate-reducing bacteria within the PRB (Figure 3).

Although influent initially entered the PRB at a rate of approximately 30 gpm, it quickly decreased to and remained at 5 gpm due to intake buildup of suspended alluvial silica and breakdown of the apatite. Subsequent system optimization conducted by researchers from INL and IDEQ involved replumbing of the intakes, which had little effect on the rate of treatment flow. In addition, INL injected air into both treatment cells during a single event last spring in order to aerate the apatite medium and to decrease overflow at both of the cell inlets. Air sparging resulted in a 7- to 15-fold temporary increase in treatment flow and cessation of the overflow. Overall results indicate that mixing of apatite with pea gravel did not improve the rate of treatment flow or decrease performance of the system.

A total of approximately 150 pounds of lead, 100 pounds of cadmium, and 10,000 pounds of zinc were sequestered in the vault during the demonstration, over 80% of which collected in the first two treatment chambers of both cells. As of mid 2005, field investigations suggested that about 40% of the barrier was spent. The reactive media consequently were removed from the apatite/gravel cell and disposed onsite as non-hazardous waste later in the year. The cell was re-filled with limestone in the first chamber and a mixture of apatite and plastic packing rings (to provide additional aeration) in the remaining four chambers.

Due to its extremely high concentrations relative to lead or cadmium, zinc is expected to serve as the indicator of PRB break-through. Longevity of the PRB will depend upon the ability to reduce system plugging and maintain an adequate rate of treatment flow. Construction of the PRB cost more than $500,000, including $35,000 for 100 tons of Apatite II.

Similar performance results were demonstrated for an apatite PRB at the Nevada Stewart Mine Site near Wallace, ID, where routine air injections are performed to reduce system plugging. Animal toxicity studies conducted by the IDEQ at that site (using the invertebrate Ceriodaphnia dubia and the fathead minnow Pimephales promelas,) demonstrated complete toxicity removal for both species from contaminated water that had passed through the PRB. Additional microbiological studies recently conducted at New Mexico State University (NMSU) suggest that apatite can induce biodegradation of contaminants such as perchlorate, TNT, and RDX.

Contributed by Bill Adams, EPA Region 10 (adams.bill@epa.gov or 206-553-2806), Neal Yancey, INL (neal.yancey@INL.com or 208-526-5157), James Conca, Ph.D., NSMU (jconca@cemrc.org or 505.706.0214), and Judith Wright, Ph.D., PIMS NW, Inc. (judith@pimsnw.com or 505.628.0916)

MWTP Demonstrates Integrated Passive Biological System for Treating Acid Rock Drainage

The U.S. EPA and U.S. DOE recently completed a four-year, pilot-scale demonstration of a passive biological system for treating ARD at the Surething Mine near Elliston, MT. Mining of gold, zinc, and lead at this mine from the late 1800’s until the mid 1950’s exposed sulfide mineralization to the environment, which led to ARD discharge from the mine adit. In addition to being highly acidic, the ARD contained elevated concentrations of iron, aluminum, copper, zinc, lead, arsenic, cadmium, and manganese. This demonstration was one of several sponsored by the Mine Waste Technology Program to identify effective source-control technologies for retarding or preventing acid generation at mining sites.

The technology’s multi-stage process at the Surething Mine involved sequential passage of ARD from the mine adit through three adjacent anaerobic reactors and an aerobic reactor. Anaerobic treatment relied on sulfate-reducing bacteria that reduced dissolved sulfate to hydrogen sulfide, which reacted with dissolved metals to form insoluble metal sulfides. This bacterial metabolism also produced bicarbonates that increased pH of the ARD and limited dissolution of metal. Seven of the eight target metals were addressed through the anaerobic process.

The treatment system was constructed in the summer of 2001. It was designed to treat a maximum ARD flow rate of 2 gpm, although rates varied due to seasonal influences and reached 10 gpm during spring runoff. The first anaerobic reactor through which ARD passively flowed was constructed of a mixture of cow manure and walnut shells. Cow manure provided a source of easily degradable organic carbon and large populations of sulfate-reducing bacteria. The walnut shells provided a longer-term source of organic carbon and the structural strength needed to maintain permeability of the mixture. Bench-scale tests indicated that this initial reactor would successfully establish the sulfate-reducing conditions needed for the overall system, but also that it would be the first to fail due to bacterial incompatibility with the low pH of feed water. Sulfate-reducing capabilities also were challenged by the presence of iron ion in the ARD, 95% of which existed in the ferric state.

Drainage water then flowed passively through the second anaerobic reactor, which was constructed of limestone cobbles that added alkalinity to the water. Earlier laboratory tests indicated that the previous cell’s reduction of ferric iron to ferrous iron reduced the extent of limestone “armoring” from ferric iron precipitates during ARD residence in this reactor. The third adjacent reactor, containing the same cow manure/walnut shell mixture as the first, served as the primary driver of sulfide-precipitating reactions that removed metals from solution. With the exception of manganese, concentrations of all target metals in water exiting this reactor were below state water quality standards.

Drainage water leaving the final anaerobic reactor was aerated by routing it through 300 feet of corrugated pipe “riprap” (a sequence of small partitions placed in the pipe to increase reaction-time solution mixing). The water was allowed to aerate 2-3 hours more in an above-ground tank before passively flowing into the fourth reactor for aerobic treatment. This final reactor was constructed of a shallow, baffled limestone bed that provided an environment for indigenous manganese-oxidizing bacteria to thrive and for subsequent removal of manganese as a precipitate. After modifications were performed to the final reactor, 99% removal of the manganese was achieved and secondary MCLs were met.

Due to the ARD’s relatively long residence time in the reactor network, testing of influent and effluent concentrations of target metals and of water quality parameters was conducted only monthly. Performance monitoring included sampling of the ARD for pH and metals analysis, as well as equipment tests to ensure an adequate rate of ARD flow. During 2002-2003, intermittent plugging occurred in pipes that connected the first and second reactors, but the problem was solved by reconfiguring the feed system. Later in 2003 and 2004, aeration of water flowing into the final reactor was enhanced by installing 200 additional feet of corrugated pipe with waterfall weirs.

The demonstration concluded in October 2005 when MCLs were attained for all target metals and pH of the water returned to a neutral range (Table 2). During four years of operation, the system treated approximately 3 million gallons of ARD.

Construction of this system cost approximately $250,000. The evaluation results show that this technology provides an effective alternative to pumping and ex-situ treatment of ARD. Detailed information on this demonstration will be available in a final report to be issued by the U.S. EPA ORD later this year (at http://www.epa.gov/ORD/NRMRL/pubs/).

Contributed by Diana Bless, U.S. EPA ORD/NRMRL (bless.diana@epa.gov or 513-569-7647), Helen Joyce (helen.joyce@mse-ta.com) and Brian Park (brian.park@mse-ta.com), MSE Technology Applications, Inc. (406-494-7232)