This issue of Technology News and Trends highlights innovative applications of soil vapor extraction (SVE) and bioventing for removal of volatile organic compounds (VOCs). SVE has accounted for approximately 25% of the in situ technologies used for source control over the past 25 years, and recent years have shown rising interest in bioventing technology.

Full-Scale SVE System Operates in Tandem with Ground Water Treatment

Online Resources

Soil vapor extraction and bioventing are two of 19 remediation technologies addressed in the U.S. Environmental Protection Agency (EPA) CLU-IN web forum. Visit www.cluin.org/remediation/ for information about SVE or bioventing applications at other sites as well as guidance from EPA, U.S. Department of Defense services, and state regulatory agencies.

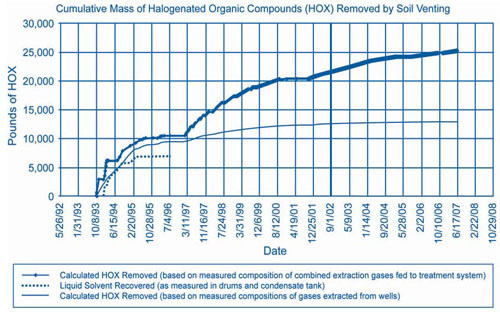

Since 1993, SVE has been implemented using two designs at the TP Industrial, Inc. (TPI) site in Gardena, CA, to treat soil contaminated with chlorinated solvents. The SVE system was modified in 1997 to improve emissions control efficiency by using carbon adsorption units that treat effluent from an air-stripping system for treating site ground water. By the end of 2007, SVE had removed a cumulative halogenated organic compound (HOX) mass of approximately 25,000 pounds.

The former TPI facility was used from 1964 through 1986 for solvent reprocessing, which involved storage of chemicals in aboveground and underground tanks. Investigations by the California Regional Water Quality Control Board in the early 1980s identified 1,1-dichlorothene, tetrachloroethene (PCE), 1,1,1-trichloroethane (TCA), methylene chloride, trichloroethene (TCE), and 1,1,2-trichlorotrifluorethane. All were found in both the saturated and unsaturated zones of two areas, with representative high concentrations reaching 1,790 mg/kg for PCE and 725 mg/kg for TCA. Site characterization indicated that the vadose zone consists of well-stratified layers of silty sand, clean sand, sandy and/or clayey silt, and silty clay. Ground water is approximately 75 feet below ground surface (bgs).

In 1986, the California Department of Toxic Substances Control (CA DTSC) began managing the site’s corrective actions. Ground water treatment began in 1988 through use of an air stripping system. Site closure activities included removal of three underground tanks and offsite disposal of approximately 2,000 yd3 of soil excavated from depths extending to 30 feet bgs. CA DTSC determined that additional excavation was infeasible, and in 1990 tested and selected in situ SVE as the most feasible remedial technology for removing the remaining HOX.

SVE operation began in 1993. The SVE network encompasses eight 2-inch-diameter vapor extraction wells screened between 16 and 66 feet bgs in two of the previously excavated areas. The wells are connected to a knock-out pot and a single 7.5-hp rotary blower that extracts soil gas from the well network at 100-130 scfm. Initial design of the system relied on refrigeration technology to condense and control VOC emissions.

After removing approximately 10,000 pounds of HOX, operation was suspended in April 1996 due to failure of the refrigeration system compressor and difficulties in attaining an emissions control efficiency of 90%, in accordance with South Coast Air Quality Management District requirements. Efficiency reduction was attributed directly to the significant VOC concentration reductions in extracted soil gas. Over the three years of operation, the system had extracted 9,200-10,300 pounds of HOX and recovered 6,700 pounds of liquid solvents that were drummed and delivered to an offsite reclamation facility.

As a consequence, the SVE system was reconfigured in July 1996 to reroute SVE gases to the existing carbon adsorption units used to treat effluent from the ground water air stripper. Soil gas is delivered to a series of three carbon adsorbers, each containing approximately 5,500 pounds of activated carbon. Air from the carbon adsorbers is exhausted to the atmosphere through the facility’s 60-foot stack.

SVE performance monitoring is conducted through 50 shallow semi-permanent vapor probes and eight deep multi-level nested vapor probes to measure soil gas concentrations across the entire site. Performance tests rely on use of a flame ionization detector (FID) for field detection of VOCs in soil gas extracted by each well. The FID sample line is connected directly to a sample port on the well while isolating the well from the rest of the system. Due to consistent field screening results, fixed-laboratory analysis is not required.

Over 10 years of operation, the modified SVE system successfully removed an additional 15,000 pounds of HOX (Figure 1). In general, measured HOX concentrations decreased as much as 80% in soil and as much as 50% in ground water. Performance monitoring in the first half of 2008 indicated that the system was operating at a flow rate averaging 110 scfm. VOCs were being removed at an average rate of 0.07 lbs/hr, slightly higher than the previous six-month period. The system had performed without interruption for 4,368 hours, with soil gas extracted continually from five of the eight SVE wells. An estimated 292 pounds of HOX were removed from the subsurface in the first half of 2008, the majority of which were captured by the carbon adsorption Installation costs for the project are estimated at $312,00. Operation of the combined treatment system costs approximately $33,000 each year, including $3,000 for electricity plus an annual change-out of carbon in the air stripping system (at a material cost of $5 per pound).

Contamination in the capillary fringe and ground water continues to serve as a source of VOCs in the soil gas. As a result, CA DTSC is negotiating an interim measure using in situ chemical oxidation (ISCO) to attack the most recalcitrant HOX contaminants, in this case chlorinated compounds such as PCE and TCE. The SVE system will continue operating until ISCO is implemented and possibly afterward if ISCO mobilizes additional contamination. Rebound testing and risk-based soil and soil gas remediation levels may be considered if mobilization does not occur.

Contributed by Richard Allen (rallen2@dtsc.ca.gov or 818-717-6607) and Andy Cano (acano@dtsc.ca.gov or 818-717-6620), CA DTSC

Bioventing Systems at Alaska Air Force Base Achieve Cleanup Closures

The U.S. Air Force and Alaska Department of Environmental Conservation (ADEC) collaborated in installing and operating seven full-scale bioventing systems over the last 10 years to address hydrocarbon and VOC contamination at the King Salmon Airport (KSA) in Alaska. Five of the systems achieved cleanup closure within five years of operation, and another is currently under closure review. The remaining system will continue operating to address light non-aqueous phase liquid (LNAPL) for an additional five years, after which sampling data will be reviewed to determine if regulatory cleanup standards have been met.

The KSA is located on the Alaska Peninsula adjacent to Bristol Bay and Katmai National Park and Preserve, approximately 280 miles southwest of Anchorage. KSA had been used as a World War II military fuel and support base and subsequently became part of a permanent state-wide air defense system. Hazardous materials formerly used and stored at the facility include diesel fuel, gasoline, oil, antifreeze, cleaning solvents, pesticides, and electrical transformers containing polychlorinated biphenyls (PCBs). Storage tanks were suspected to be the source for up to 400,000 gallons of fuel released into the subsurface.

Investigations under the U.S. Department of Defense Installation Restoration Program during the late 1980s indicated soil and ground water contamination at several KSA sites, which were segregated into seven treatment zones. High concentrations for contaminants of concern found in soil during 1994 and 1998 remedial investigations included 19,200 mg/kg for diesel-range organics (DRO), 15,000 mg/kg for gasoline-range organics (GRO), 27 mg/kg total BTEX (benzene, toluene, ethylbenzene, and xylenes), 0.26 mg/kg trichloroethene (TCE), and 2.19 mg/kg PCE.

A seep collection system was installed in 1994 to capture any source material and treat contaminated ground water before it reached an adjacent surface water body (Eskimo Creek). The collection system was shown over years to be ineffective in reducing the time to achieve the remedial action objective (RAO) of removing subsurface free product. Evaluated or implemented treatment methods to address the problem included a reactive iron wall, in situ biological treatment, bio-slurping, air sparging, bioventing, diversion walls, phytoremediation, capping, and monitored natural attenuation. Bioventing was selected in five of the seven treatment zones as a lower cost alternative with a shorter duration compared to other remedial approaches.

Six bioventing systems were installed in 1998 through 2001. Each system consisted of 1-11 venting wells extending 14-34 feet bgs with a 10- to 20-foot radius of influence per biovent. Equipment for each system consisted of an enclosed motor/blower assembly generating approximately 5-15 cfm of continuous air flow into each venting well. Four to eight vapor points per site were installed for periodic monitoring of soil gas.

Operation of the first system began in 1999, with the last going into operation in 2002 as part of a remediation process optimization (RPO) for an existing SVE system. The switch from SVE to bioventing in this treatment zone was estimated to save $2.8 million in project costs, including an annual $890,000 for operation and maintenance (O&M).

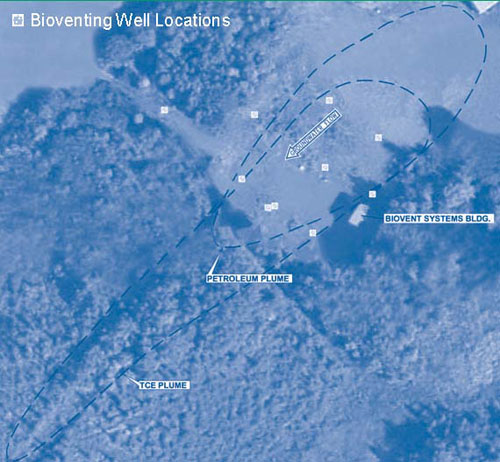

An additional RPO in 2004 resulted in expansion of the site’s radar approach control building (RAPCON) bioventing system to provide additional source treatment of diesel-range organics and free product. Expansion involved installation of four bioventing wells, which effectively enlarged the treatment area (Figure 2). Results of ground water sample analysis showed that bioventing was accelerating attenuation. At one RAPCON monitoring well, GRO and TCE pre-treatment concentrations in 1996 were 13.071 mg/L and 0.0589 mg/L, respectively. During a 2006 ground water monitoring event, GRO and TCE concentrations in the same well had reached established cleanup goals, with concentrations of 0.41 mg/L for GRO and 0.0159 mg/L for TCE.

Follow-up monitoring was conducted approximately two months after shutting down each of the five bioventing systems achieving cleanup objectives. Activities included installing two or three soil gas monitoring points and conducting a soil gas survey at existing vapor monitoring points to determine oxygen utilization. From each soil gas location, one soil sample was collected to evaluate soil gas total petroleum hydrocarbons and target contaminant concentrations. Appropriateness of system shutdown and site closure was determined through application of ADEC’s "350 determination," otherwise known as the "ten-times rule." This determination allows for a site to be considered closed once contaminant concentrations attenuate below 10 times the established cleanup level; it can be applied only to soil-impacted areas where ground water is non-potable.

RPO in 2004-05 indicated marginal performance of the sixth bioventing system, which had operated intermittently since 2001 in the vicinity of another building. Operational problems involved blower and motor overheating and inability to inject adequate oxygen, partially due to surface water infiltration. Less permeable soil, water-saturated soil, and temporary leaks in system piping combined to limit oxygen delivery in this system. Piping repairs and diversion of air flow to air injection wells within the treatment area were implemented but had limited effect. To determine whether NAPL-saturated soil could be limiting bioventing success, six direct push borings equipped with an in-situ probe for measuring laser-induced fluoroescence (LIF) were advanced. LIF results showed low average saturation (2-4%) in the smear zone at a depth of 10-12 bgs. Based on recommendations from the RPO team and finalization of RPOs, ADEC recently granted approval for conditional closure with long-term monitoring and institutional controls.

The seventh bioventing system, which continues to operate, combines a bioventing curtain with a carbon-based pump and treatment system. This system was installed in 2003 to reduce LNAPL mobility and reduce continuing migration of hydrocarbons and TCE into the onsite creek. The bioventing curtain focuses on remediating the smear zone and augmenting natural attenuation, which was found to be occurring despite the cold climate. It consists of wells distributed across a contaminant plume perpendicular to ground water flow, in order to oxygenate ground water before entrance to the creek. This combined treatment strategy allowed complete shutdown of the ground water seep collection system, consequently reducing annual O&M costs by approximately $300,000 and potentially reducing long-term project costs by an estimated $40 million.

Abandonment of all KSA bioventing wells will be completed under a future base-wide well abandonment and maintenance effort. The U.S. Air Force Center for Engineering and the Environment (AFCEE) estimates that installation and operation of the five bioventing systems reaching cleanup closure cost approximately $1.2 million and accelerated cleanup closure by decades when compared to monitored natural attenuation. More information about AFCEE's bioventing initiative, which has involved more than 150 bioventing systems at more than 30 sites, is available at www.afcee.af.mil/resources/technologytransfer/.

Contributed by Lori Roy, U.S. Air Force (lori.roy@elmendorf.af.mil or 907-552-7697), Charley Peyton, U.S. Air Force (charley.peyton@elmendorf.af.mil) and Jonathan Schick, ADEC (jonathan.schick@alaska.gov)

SVE Interim Remedial Measure on Long Island Meets Response Action Goals

Northrop Grumman Corporation (NGC) is successfully implementing SVE as an interim remedial measure (IRM) to mitigate offsite migration of VOCs in soil gas from the Bethpage Community Park in the Town of Oyster Bay on Long Island, New York. The IRM is being conducted per an Order on Consent with the New York State Department of Environmental Conservation (NYSDEC) and in conjunction with a pump and treat IRM for ground water. Performance and compliance monitoring during the first year of SVE operation have indicated that response action goals are being met, allowing parts of the IRM to be rebalanced or eliminated.

The Bethpage Community Park was previously the site of the former Grumman settling ponds area, which received chemical waste from the neighboring Grumman Aircraft Engineering Corporation (now NGC) property. NGC donated the property to the Town of Oyster Bay in 1962 for development of the park. Since the 1960s, the 18-acre park was open to the public for swimming, ice skating, picnicking, and other recreational activities. Discovery of PCBs and metals above state guidelines in surface soil at the NGC property and shallow soils in the park prompted closure of portions of the park in 2002, excavation of contaminated surface soil, and further site investigations. Soil and ground water at the park were found to contain VOCs at elevated levels that raised concern for potential inhalation risk to nearby residents.

Native soil at the site consists of sand with interbedded lenses of silt, clay, and gravel. Depth to ground water is approximately 55 ft bgs, but perched ground water is present locally atop a low-permeability zone, which is encountered 36 to 46 feet bgs and ranges in thickness from 1 to 20 feet. The average horizontal conductivity of the upper glacial deposits is approximately 270 ft/day, and shallow ground water flows south-southeast at about 1 ft/day. Some areas of the site contain fill materials at varying depths.

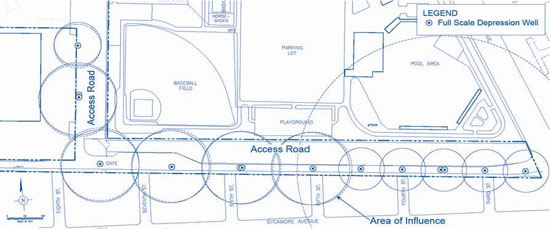

Soil vapor samples collected in March 2007 were found to contain PCE, TCE, and isomers of dichloroethene (DCE). TCE was present at concentrations up to 17,000 mg/m3, which exceeds NYSDEC’s short-term guideline concentration (SGC) of 14,000 mg/m3. NGC completed installation of the SVE system along the facility’s access road at the southern and western borders of the park in early 2008 to prevent offsite migration of VOC soil vapor (Figure 3).

Four depressurization wells and 10 vacuum monitoring wells were installed in a line about 400-feet long along the western access road, while 14 depressurization wells and 37 vacuum monitoring wells (VCMs) were installed in a line about 1,300-feet long along the southern access road. The clustered depressurization wells have 5- to 20-foot-long screens, while the VCMs have 1-foot screens. Depths of the wells range from 7- to 50-feet bgs.

Two 20-hp and one 30-hp regenerative blowers were installed to generate a vacuum within the vadose zone and draw the vapor stream through the emissions control system. The system was designed to maintain an average negative pressure of -0.1 inches of water column (iwc) along the access road to prevent offsite migration of soil gas.

Three 52-gallon moisture separators were installed to remove condensate from the influent vapor stream and direct it to a 400-gallon bulk storage tank for offsite treatment. A heat exchanger conditions the effluent vapors prior to passing it through a vapor-phase granular activated carbon bed (VPGAC) for treatment. Treatment was to continue until all VOCs in the influent vapor stream were less than the NYSDEC annual guidance concentrations (on a 12-month rolling average) and less than SGCs for any given grab sample. Once the final remedies are selected, NGC will propose SVE closure criteria.

Continuous operation of the SVE system began in February 2008 with brief shutdowns due to routine maintenance and troubleshooting. Performance monitoring showed that the average induced vacuum was about three times greater than the -0.1 iwc design. As a result, the system was rebalanced in March 2008, and two of the blowers and the heat exchanger were put on standby. In addition, manifold control valves were adjusted, as needed, to lower or raise the vacuum and flow at various wells to obtain values closer to their design criteria.

Influent and effluent vapor streams were monitored monthly at vapor sampling ports from February through December. Total concentrations of VOCs in the influent vapor samples decreased from a maximum of 20,622 µg/m3 at system startup to a minimum of 1,966 µg/m3 in December. The concentration of TCE was reduced from above the SGC to 710 µg/m3.

VOC concentrations in effluent released to the atmosphere also complied with state criteria. A detailed air-emissions regulatory review summary and site status prepared in December 2008 demonstrated that untreated air emissions from the SVE system met applicable regulatory criteria. Therefore, the VPGAC was deemed no longer necessary to treat influent soil vapors and was removed from service in January 2009. The piping has been modified accordingly.

The SVE system meets the design criteria and prevents potential impacts to nearby residences. The soil vapor IRM will continue to operate according to the rebalanced system parameters. Now that the VPGAC bed has been removed, having continuously met influent and effluent criteria, NGC and NYSDEC agreed to reduce sampling frequency from monthly to quarterly. Further information on the site is available at www.dec.ny.gov/chemical/35727.html.

Contributed by Steven Scharf (sxscharf@gw.dec.state.ny.us or 518-402-9620) NYSDEC

Superfund Redevelopment Webinars

EPA is hosting a series of monthly CLU-IN seminars on the redevelopment of Superfund sites across the country, as part of a 10-year anniversary of the Agency’s Superfund Redevelopment Initiative. The opening seminar provided an overview of different types of site reuse, such as parks and recreation, ecological revitalization, renewable energy, residential, commercial, and multi-use. In subsequent sessions, remedial project managers will describe redevelopment case studies on sites such as the Pemaco Superfund site in Maywood, CA, and the South Point Plant Superfund site in South Point, OH. Registration for upcoming seminars is available at www.clu-in.org/sri/. Archived seminars (April 29 and May 21) can be viewed at www.cluin.org/live/archive.

The Interstate Technology and Regulatory Council (ITRC) now offers the two-day training course Vapor Intrusion Pathway: A Practical Guideline. Training will be held in Sacramento on June 22-23 and Long Beach, CA, on June 25-26. To register or obtain more information, visit www.itrcweb.org/crt.asp.