This issue of Technology News and Trends highlights passive treatment systems (PTSs) used to treat mining influenced water (MIW) at former or current hard rock mines. Each PTS uses a biochemical reactor (BCR) supported by remediation polishing technologies such as aerobic wetlands or limestone beds. As passive systems, these technologies rely on natural hydraulic gradients (and in some cases renewable energy sources) to transfer impacted water from mine adits and seeps to the ground-surface treatment cells.

Full-Scale PTS Uses Six-Step Process to Treat Polluted Mine Discharge

Online Resources

EPA offers basic information about addressing Abandoned Mine Lands (AML) at www.epa.gov/superfund/programs/aml/index.htm. Reports on research, assessment, and remediation of mining waste at Superfund sites are available at www.epa.gov/superfund/programs/aml/tech/. More information soon will be available on the CLU-IN Web pages for mining sites at www.cluin.org/issues/default.focus/sec/mining_sites/

cat/overview. In addition, the Interstate Technology and Regulatory Council (ITRC) provides information to assist in the selection of mining waste treatment technologies at www.itrcweb.org/miningwaste-guidance/.

The U.S. Environmental Protection Agency (EPA), University of Oklahoma, and other federal, state, local, and tribal partners collaborated in 2004 to design a PTS on part of the 40-square-mile Tar Creek Superfund site in northeast Oklahoma. The PTS treats artesian groundwater that has discharged from abandoned underground lead and zinc mines into a tributary of Tar Creek for over 30 years. Periodic sampling since completion of the PTS in December 2008 has shown that the passive treatment train is effective in removing metals from MIW and has significantly reduced concen-trations of metals in the output to the Tar Creek tributary. The PTS is the first full-scale MIW treatment system in the 100-square-mile Tri-State Mining District, which extends into Kansas and Missouri.

During active mining, about 50,000 m3/day of groundwater were pumped from under-ground mines in the area. Mining ceased in the early 1970s, and by 1979, MIW with high levels of heavy metals was seeping to the surface, contaminating surface water. The PTS was installed at Mayer Ranch, a private property where sampling of seeps from two old mining boreholes showed concentrations as high as 192,000 µg/L iron, 11,000 µg/L zinc, 970 µg/L nickel, 60 µg/L lead, and 17 µg/L cadmium from 2004 to 2008. The seeps discharged at a rate ranging from 570 to 950 L/min and had a pH of 5.95.

The PTS was designed to treat a metal-rich influx of 1,000 L/min and remove a target 20 g/m2/day of iron. The goal was to decrease receiving stream concentration of iron, zinc, lead, and cadmium to the Criterion Continuous Concentrations suggested by EPA's national recommended water quality criteria for freshwater aquatic life.

Construction began with the capture and hydraulic control of seeps through rotosonic over-drilling and placement of casing over the two known boreholes. This also allowed for further quantification of flow rates and variability. During subsequent construction activities, a third artesian borehole was discovered and incorporated into system design. Stormwater was diverted using existing channels and burrows excavated by adjacent landowners for private use.

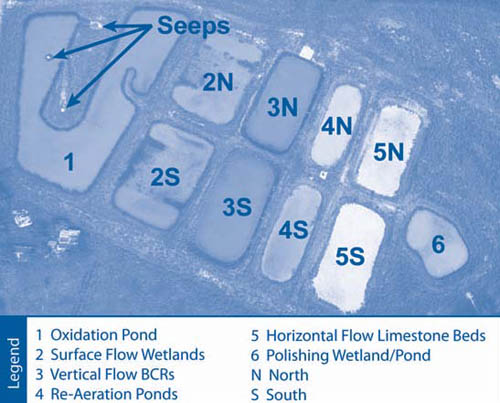

The completed PTS includes six distinct process units that include parallel treatment trains (Figure 1) to allow for maintenance and estimation of variance in performance. The system was consolidated into a compact "footprint" area (about 2 ha) to comply with construction requirements adjacent to an existing utility corridor.

The first process unit is an oxidation pond that receives the artesian MIW and oxidizes and hydrolyzes the Fe2+. Oxidized iron then settles out as iron oxyhydroxide solids. Effluent water flows by gravity feed to the two parallel surface water wetlands. Emergent vegetation in the shallow zones (<0.3 m) increases retention time of solids, while the deeper pools facilitate settling of oxidized and hydrolyzed iron solids from solution. Water then flows to the third process unit comprising parallel vertical-flow BCRs designed to provide a reducing environment to remove cadmium, lead, and zinc. The BCRs were constructed with a 45-cm layer of organic substrate (a mixture of 45% spent mushroom compost, 45% hardwood chips, and 10% manufactured limestone sand) overlying a 30-cm limestone gravel drainage layer containing perforated drainage pipes. A low-permeability HDPE liner beneath the gravel maintains design integrity.

In the fourth process unit, submerged aeration systems in two parallel aeration ponds re-oxygenate water from the BCRs. Aeration reduces odors caused by the emission of hydrogen sulfide gas during bacterial sulfate reduction. Water in one pond is aerated by a vertical displacement pump powered by a 20-foot-tall windmill; as a result, water is aerated only when the wind is blowing. Water in the adjacent pond is aerated by a high-volume compressor powered by a 120-watt photovoltaic (PV) system that charges a deep-cycle battery. The PV system operates the compressor on a 20-hours-on, 4-hours-off cycle. Horizontal-flow limestone beds in ponds of the fifth process unit further improve water quality by removing additional zinc and manganese and increasing water hardness to offset the bioavailability of any remaining trace metals. The limestone beds are greater than 1 meter thick to provide a minimum 14-hour retention time.

The final polishing pond/wetland facilitates settling of residual solids through vegetative filtration and re-aerates water through passive photosynthesis. Water from the pond discharges via an exit pipe into a small channel that feeds into the Tar Creek tributary. The wetlands provide a wildlife habitat and serve as a buffer between the PTS and the tributary and its associated riparian zone.

Water quality entering the tributary has improved substantially since installing the PTS. Output of iron has decreased to 440 µg/L, while outputs of zinc and nickel were decreased to 450 µg/L and 160 µg/L, respectively. Levels of cadmium, lead, and arsenic are below detection limits, and pH has increased from 5.95 to 7.11. The PTS retains approximately 57,000 kg iron, 3,300 kg zinc, 300 kg nickel, 5 kg cadmium, 17 kg lead, and 18 kg arsenic per year. Beneficial reuse of accumulated solids and substrates retained by the system is being explored as researchers continue to study receiving stream biogeochemistry, fish and macroinvertebrate communities, microbial community activity, and degree of bioaccumulation potential.

Design and construction of the Mayer Ranch PTS cost $1,196,000. The system is expected to last 25 years, with an estimated $20,000 annual operation and maintenance (O&M) cost. Total costs (including research) are estimated at $4 million.

Errata

To clarify information in the March 2011 article, "3D-CSIA Forensics at the FAMU Law School Site Reveals Multiple Contaminant Sources," the Florida Department of Environmental Protection's (FDEP) Site Investigation Section (SIS) conducted the study to assess groundwater quality and identify potentially responsible parties. The owner of one facility at which a release occurred is responsible for remediation and is working with the FDEP District Office to coordinate cleanup of their release. Upon completion of the SIS report, FDEP will determine if additional facilities/properties will require further assessment and/or remediation activities.

Other cleanup activities at the Tar Creek Superfund site include the processing of chat for resale, remediation of distal properties, and the reinjection of mining wastes into mine cavities. EPA recently finalized a hydrogeological study that concluded that reinjection of mining waste into the mine workings complies with Underground Injection Control requirements. Cleanup began in 2010 and is expected to take 30 years to complete.

Contributed by Robert Nairn, Ph.D., University of Oklahoma (nairn@ou.edu or 405-325-3354), and Ursula Lennox, (lennox.ursula@epa.gov or 214-665-6743) and Gary Baumgarten, EPA Region 6 (baumgarten.gary@epa.gov or 214-665-6749).

EPA Evaluates Performance of a Cold-Climate, High-Elevation PTS

EPA Region 8 is monitoring performance of a PTS consisting of a BCR and an aerobic polishing cell (APC) at the 10-acre Standard Mine Superfund site in Gunnison County, CO. The Engineering Technical Support Center of EPA's Office of Research and Development (ORD) worked with Region 8 to construct the pilot-scale PTS to evaluate its efficacy during the harsh winter conditions at the site's high elevation (11,000 feet above mean sea level). To date, this is the only known PTS above 10,000 feet. Performance evaluation in late 2009 indicated that the BCR was removing, on average, more than 98% of the contaminants of concern (COCs) (cadmium, copper, lead, and zinc) influent concentrations and 91% of the total iron influent concentrations. More recent data analyzed by ORD show that the APC is increasing dissolved oxygen and reducing effluent toxicity.

Lead, zinc, silver, and gold were mined at Standard Mine from the 1870s until 1966 when the mine was abandoned, but remaining wastes continue to affect the area's surface water. Prior to PTS installation, outflow from the mine adit drained into Elk Creek, which is a tributary of Coal Creek. Together, these creeks supply municipal drinking water for the Town of Crested Butte. Highest measured concentrations of the primary COCs (for aquatic life) in the adit water are 0.201 mg/L dissolved cadmium, 0.454 mg/L dissolved copper, 89.815 mg/L total iron, 0.381 mg/L dissolved lead, 13.24 mg/L dissolved manganese, and 31.9 mg/L dissolved zinc. The Colorado water quality standards for discharge to Elk Creek (based on chronic toxity for a metal hardness value of 65 mg/L) are 0.31 µg/L cadmium, 6.2 µg/L copper, 1.6 µg/L lead, 1,430 µg/L manganese, and 86 µg/L zinc.

PTS construction began in 2007 with installation of the BCR. The BCR consists of a 5-foot-deep geomembrane-lined cell filled with 30% (by weight) limestone along with wood chips, manure, and hay totaling approximately 5.5 tons of organic material (Figure 2). This reactive substrate provides an organic carbon source for microbial population and promotes biological reduction of sulfate and removal of metals as metal sulfide precipitates.

Two PVC pipes carry MIW from the adit to a 500-gallon buried tank by way of gravity feed. During periods of high flow, tank overflow is diverted to the nearby Elk Creek. From the storage tank, MIW is pumped through a flume to the BCR at an average rate of 1-1.5 gpm. Pump operation is automated by an electric timer powered by a 90-W PV system equipped with a series of 12-volt, deep-cell, marine-grade batteries.

The BCR became operational in late 2007, and construction of the APC was completed in 2008. Following an average three-day residence within the BCR, the effluent drains via gravity to the APC through use of a stand-pipe flow splitter housed in a nearby shed. The APC encompasses a series of cascading cells with open water and a limestone rock cell. The APC's primary role is to reduce manganese, increase dissolved oxygen, and return parameters such as total suspended solids, ammonia, nitrite/nitrate and E. coli to concentrations below applicable water quality standards. Treated effluent from the APC is discharged to a wetlands area that ultimately drains into Elk Creek.

Results from the first two years of annual monitoring (2008 and 2009) indicated that the BCR demonstrated an average metal removal efficiency of approximately 98%, for the primary COCs. Iron was removed by the BCR at an average removal efficiency of 92% in 2009 and 97% in 2010. Monitoring of the APC effluent showed manganese concentrations ranging from 4.78 mg/L to 10.01 mg/L in 2009, and limited sampling in 2010 showed concentrations of 0.05-3.04 mg/L.

Due to harsh winter conditions, the site is accessible for routine sampling and O&M activities from only July to October of each year. As a result, several sampling procedures have been used. During the winter and spring, samples from the BCR influent and effluent were initially collected by autosamplers, and grab samples were collected during routine monthly maintenance visits. Currently, sonde units are used to remotely measure water quality parameters such as pH, temperature, and oxidation-reduction potential on a continuous basis. The sonde data are stored in an onsite data logger and transmitted by satellite to end users in Denver, allowing real-time access to the field information. All power for the monitoring system is provided by the onsite PV system.

The constant presence of flowing water prevents freezing and allows the system to operate year-round. In early 2009, PTS operations were suspended intermittently over about 15 weeks due to pump failure, infiltration gallery clogging, and delivery pipe clogging. Failure of the pump timer was attributed to hydrogen sulfide buildup that corroded wires. This problem was rectified by replacing the pump wires and enclosing all PTS wiring in metal conduits to minimize exposure to sulfide gas. Other maintenance included replacing the original submersible pump, which appeared to fail prior to its expected 400-hour life due to metal precipitation and corrosion. Trial use of an alternate, diaphragm-style pump was unsuccessful after one month as a result of freezing and led to installation of a third, more robust submersible pump in late 2009.

Upgrades to the piping system that carries water between the mine adit and storage tank also were implemented. High spring flow conditions were found to cause a backup that released adit discharge on the ground surface across the site. The original pair of 2-inch-diameter PVC pipes was consequently replaced by a pair of 4-inch lines buried in 2-4 feet of pea gravel , but the piping remains vulnerable to sediment clogging and iron hydroxide precipitation.

Conditions such as pH in the mine adit remain steady. Based on parameters such as influent and effluent concentrations of sulfate, sulfide, and calcium, as well as biochemical oxygen demand, the BCR continues to operate successfully. Overall results suggest the PTS can effectively reduce the COCs (except manganese) under harsh winter conditions and high elevations. The PTS is not meeting in-stream standards, but the pilot-scale BCR is treating only a fraction of the water coming from the mine. Based on the estimated dissolution rate of limestone and an assumed 90% operation rate, a sufficient volume of limestone is expected to remain in the BCR for four years.

Factors undergoing evaluation include COC concentration reductions, demonstrated life of the pump and remote monitoring system, and effectiveness of the corrosion corrective actions and changes to the influent lines to reduce plugging. Performance evaluation includes collection of PTS influent and effluent flow and water quality data during high-flow, low-pH spring runoff conditions.

The cost of design, construction, and materials for the pilot-scale PTS totaled approximately $175,000, including $50,000 for excavation and earth-moving, $10,000 for sampling equipment, and $12,000 for the PV and satellite equipment. EPA Region 8 will use the pilot-scale results to evaluate potential construction of a full-scale PTS. The capital cost for a full-scale PTS expected to operate over 30 years (at a flow rate of 20 gpm) is estimated at $750,000, with an estimated $25,000 annual O&M cost.

ORD continues to work with EPA regions to build PTSs at other mining sites. Components of other PTSs may include a chitin reactor, which was originally constructed as an alternate remediation polishing component of the Standard Mine PTS but suspended after two months of operation due to apparent construction failure.

Contributed by Christina Progess, EPA Region 8 (progess.christina@epa.gov or 303-312-6009) and David Reisman, NRMRL (reisman.david@epa.gov or 513-569-7588).

BCR and Wetlands Treat MIW at Remote Site in White Mountain National Forest

The U.S. Department of Agriculture (USDA) Forest Service and the Plymouth State University Center for the Environment (PSU) are monitoring performance of a full-scale PTS that began operating in 2009 as part of removal actions at the abandoned Ore Hill Mine site near Warren, NH. The system encompasses a BCR and adjoining wetlands constructed after discovery of an MIW seep, which continued to cause elevated metal concentrations in surface water despite earlier cleanup efforts. As of late 2010, the PTS was reducing metal concentrations in the MIW by more than 90%.

A one-mile undeveloped road provides access to this remote 10-acre site. From December through April each year, a quarter of the stretch requires use of snowshoes. The site was mined intermittently for lead, copper, and zinc from the 1830s until approximately 1915 when the mine was abandoned. The property eventually became part of U.S. forestland, but mining left behind piles of waste rock and tailings, and surface water drainage from the site exhibited high levels of dissolved metals and low pH.

The drainage impacted downstream water quality and aquatic life in Ore Hill Brook; approximately five miles of the stream were added to the state's 303(d) list of impaired waters in the Baker River watershed. In addition, a portion of the Appalachian National Scenic Trail that passed through the site was re-routed in 1979 to a nearby corridor, due to the waste piles. The highest measured concentrations of COCs in onsite MIW prior to removal actions were 14.25 mg/L aluminum, 1.42 mg/L copper, 1.85 mg/L lead, and 46.25 mg/L zinc, with a pH as low as 3.46. These concentrations exceeded state water quality criteria for protection of aquatic life by 2.5 to 3.3 orders of magnitude.

In the 1980s, initial cleanup was conducted through limestone capping of 4.5 acres of consolidated waste piles, revegetating soil-capped areas, and lining selected surface water channels with limestone. Continued downstream contamination and MIW seeps through the soil caps led to a 2006 removal action focused on controlling the contaminant source and reducing offsite migration of hazardous metals in surface water. The goal was to meet state surface water quality criteria for pH and metals.

The removal action involved excavating approximately 35,000 yd3 of mine tailings and waste rock with high hazardous metal content, mixing it with a phosphate-based amendment to reduce metal availability, and transferring the treated material to an onsite, unlined, soil-capped repository. Phosphate was selected after a treatability study found it was as effective as Portland cement in reducing metals content in the leachate from tailings, and the resulting repository would not require the lining and capping design typical of a Portland-cement repository. Post-construction monitoring of downstream surface water found that metal concentrations were 80% lower, but did not reach the expected 90-95% metal reduction.

During the 2006 excavation, a previously undiscovered adit was encountered. Seep from the adit flowed at a rate of 1 gpm across 200 feet of bedrock into a shallow pond within a former quarry pit (covering approximately 50 by 100 feet and extending 15 bgs) before continuing downgradient. As an interim effort to slow surface water movement and control erosion, 13 sediment check dams were installed within the tailings excavation area.

In 2008, the Forest Service constructed and monitored performance of a pilot-scale, temporary BCR to evaluate its design and efficacy in addressing the newly discovered adit seep. The pilot-scale results and findings from a PSU study on surface water within the 2006 excavation area were used the following year to construct a full-scale BCR along with an aerobic wetlands area as part of a second removal action. Full-scale BCR construction involved excavating sediment from the existing pit/pond and lining it with 900 yd2 of geosynthetic clay. The BCR base was plumbed with a 720-foot network of 4-inch-diameter piping and equipment to control inflow of MIW diverted from the adit and outflow to the constructed wetlands. A shallow overflow channel was constructed along the BCR perimeter to manage high flow during stormwater events.

A total of approximately 130 tons of reactive substrate containing (by weight) 2.5% manure, 47.5% wood chips, 10% hay, and 40% limestone were placed in the approximate 90- by 40-foot BCR (Figure 3). The wood chips and hay were obtained from local producers and mixed at a nearby dairy farm providing the manure. The reactive substrate was hauled in batches three miles to the site. Following final placement of the substrate, the BCR remained closed at its base for approximately 30 days to provide an incubation period and increase growth of microbial populations in the substrate.

The wetland was constructed approx-imately 100 feet downgradient of the BCR. Due to the ground slope and the need for shallow wetlands, the design called for two constructed wetland cells operating in series and covering a total of about 5,600 ft2 (Figure 4). In July 2009, two thousand plugs of various native species were planted in the wetlands by high school students participating in a Forest Service training program.

MIW began flowing through the complete PTS in September 2009. Upon exiting the PTS, the treated water flows along an existing surface water channel and enters Ore Hill Brook approximately 300 feet downgradient.

Since start-up, the rate of MIW flow through the BCR has been estimated at approximately 2-5 gpm. Five quarterly sampling events have been conducted to measure metal concentrations and water quality parameters in the BCR influent and effluent as well as the wetlands effluent. Limited sampling results to date indicate the PTS is performing as expected, with cadmium, copper, and zinc concentrations in the BCR effluent decreasing 93%, 90%, and 93%, respectively. A lower (65%) reduction for lead may be due to significant variation in its influent concentrations, which ranged from 0.0156 to 0.6956 mg/L over the five sampling events. Additional removal of cadmium, copper, lead, and zinc appears to be occurring in the wetlands. Due to inflow below the BCR, the PTS has not quite met the overall long-term water quality criteria; however, surface water quality is significantly improved.

O&M has included quarterly site inspections and water quality measurements. The monitoring is conducted through a Forest Service cooperative agreement initiated in 2006 with the PSU Center for the Environment. The Forest Service anticipates continued PTS monitoring and work with the New Hampshire Department of Environmental Services to evaluate performance of the BCR and overall PTS in reaching state water quality criteria.

Engineering Issue

More information about managing and treating MIW at sites such as these is detailed in the EPA National Risk Management Research Laboratory's Management and Treatment of Water from Hard Rock Mines engineering issue (EPA/625/R-06/014) available at: www.epa.gov/nrmrl/pubs/625r06014/

625r06014.pdf.

Construction costs for the full-scale PTS totaled approximately $175,000. The BCR is expected to operate effectively for 18 years, at which time its substrate is expected to require replacement.

Contributed by Tim Buxton, USDA Forest Service (tbuxton@fs.fed.us or 603-466-2713) and Aaron Johnson, PSU Center for the Environment (ajohns17@plymouth.edu or 603-535-3269).