- Featured Articles

- Treatability Testing: Biostimulation and Bioaugmentation of a TCE Groundwater Plume on Tribal Land

- Full-Scale Application: Source Area Biostimulation Combined with a Biobarrier

- Resources

- CLU-IN Website

- Upcoming Report

- ESTCP Cost & Performance Report

- A Citizen's Guide

- Upcoming Training

- Conference Proceedings

Download This Issue in Adobe PDF® Format

Download This Issue in Adobe PDF® Format

(1.68MB/10pp/PDF)

This issue of Technology News & Trends highlights the use of in situ bioremediation to address groundwater contamination caused by past releases of organic contaminants. Implementation of bioremediation at these sites involves biostimulation techniques in which amendments are administered to the subsurface to provide nutrition for microorganisms capable of consuming and consequently biodegrading the contaminants, as well as bioaugmentation techniques involving subsurface injection of biodegrading microorganisms that may not already exist onsite.

FEATURED ARTICLES

Treatability Testing: Biostimulation and Bioaugmentation of a TCE Groundwater Plume on Tribal Land

Contributed by Fred McDonald, Tulalip Tribes; Denise Baker-Kircher, U.S. Environmental Protection Agency Region 10; Carl M. Bach, The Boeing Company; Clint Jacob and Christophe Venot, Landau Associates Inc.

The Boeing Company is performing an in situ treatability test on a groundwater plume containing trichloroethene (TCE) and TCE breakdown products at the company�s former aerospace test facility near Seattle, Washington. The treatability test evaluates bioremediation efficacy as part of a remedial investigation and feasibility study (RI/FS) for four dissolved-phase TCE plumes affecting 26 acres of this 525-acre site. The RI/FS is conducted under a Superfund alternative approach,that involved negotiation with the U.S. Environmental Protection Agency to use Superfund processes and standards but without site listing on the National Priorities List. Preliminary treatability test results along with earlier pilot-scale testing indicate that effective sequential reductive dechlorination of TCE and breakdown products can be achieved through biostimulation and bioaugmentation.

The site is located within the Tulalip Tribes Indian Reservation in Marysville, Washington, and was leased by Boeing from the Tribes in 1960 to 2001. Bioremediation testing focuses on one 4.3-acre groundwater plume originating from a former aeronautical test area and septic tank. This plume contains the highest TCE concentration in groundwater, with a maximum concentration of 500 µg/L identified during 1999-2010 remedial investigation. TCE breakdown product cis-1,2-dichloroethene (cis-DCE) was present at baseline concentrations reaching 200 µg/L. However, breakdown products vinyl chloride (VC), ethene, and ethane were not detected.

The plume extends nearly 900 feet in length and 25 to 45 feet in depth in an unconfined, glacial sand aquifer with low organic carbon. Average groundwater seepage velocity in this area is 0.5 to 1 foot/day. Prior to pilot testing, baseline aquifer redox conditions were aerobic to mildly reducing. The distribution of higher TCE concentrations downgradient of suspected source areas suggests that the site�s four plumes resulted from releases of aqueous rather than dense non-aqueous phase liquid.

Figure 1. Feasibility study area with seven rows of wells to inject electron donor substrate and bacterial inocolum.

Pilot testing was performed intermittently from 2000 through 2010 to identify an optimal electron donor substrate for biostimulation, evaluate use of bioaugmentation to overcome cis-DCE reduction "stall" (no further degradation), and obtain design parameters for potential full-scale bioremediation. Testing evaluated the use of a single row of injection wells oriented perpendicular to the plume axis (Figure 1) and relied on natural groundwater flow to distribute the substrate. An emulsion of sodium lactate (1.5%) and soybean oil (2%) was the most effective of various electron donor substrates tested alone and in combinations, including HRC,™ chitin, and other vegetable oil and lactate products. Use of the optimal lactate and oil substrate resulted in highly reducing (i.e., sulfate-reducing to methanogenic) conditions, complete dechlorination, and more than six months of donor longevity between injections. Following various donor injections but prior to bioaugmentation, cis-DCE stall was indicated by increasing cis-DCE concentrations of up to 1,400 µg/L.

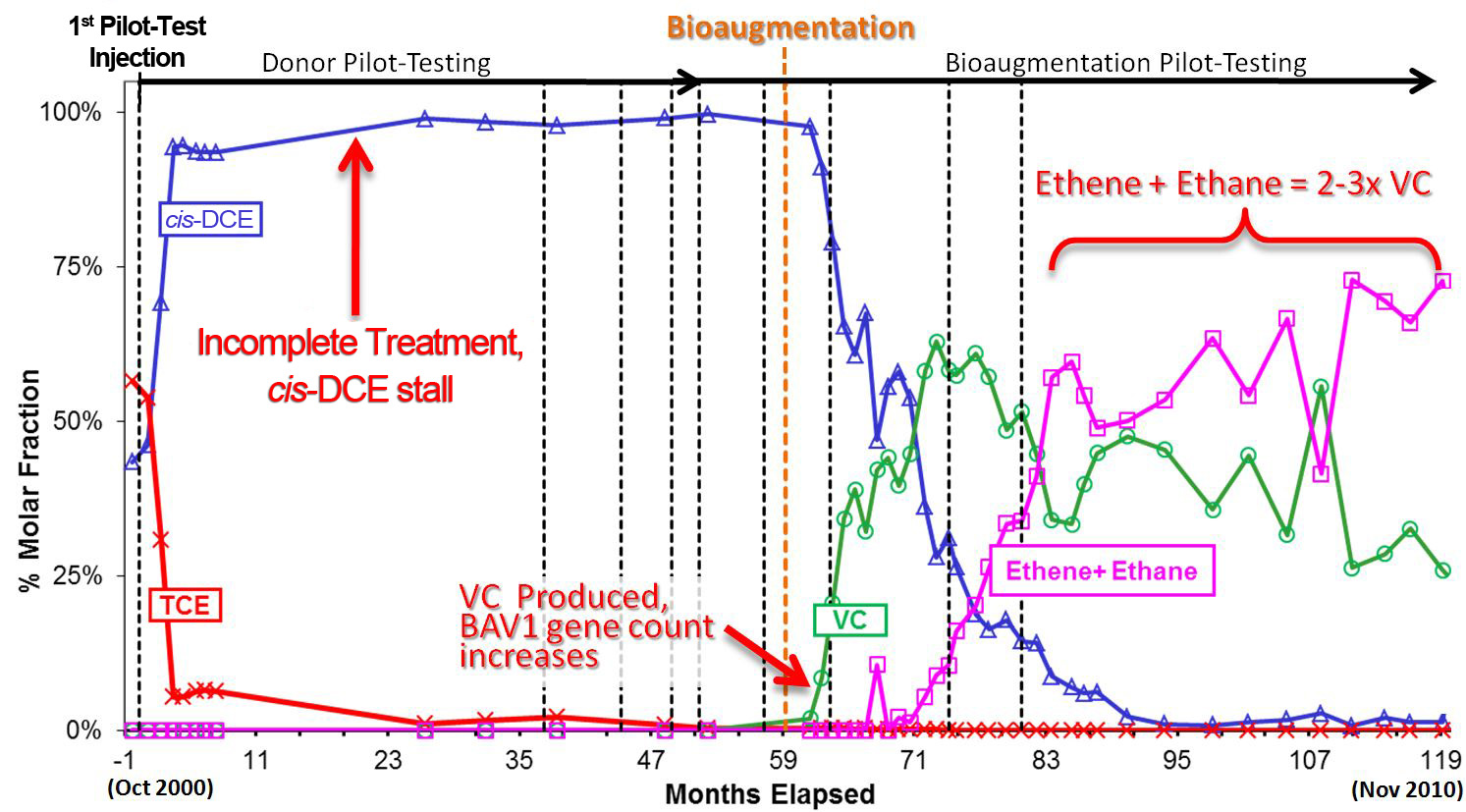

Pilot-scale bioaugmentation tests began after the third donor injection by injecting the Bachman Road strain (BAV1) of Dehalococcoides (DHC) bacteria. DHC are the only microorganisms known to reductively dechlorinate cis-DCE and were not detected in the plume prior to bioaugmentation. Substantial VC and ethene production occurred after one injection of DHC BAV1. This increase had not been observed following injections of lactate and oil alone. Near the end of testing, two to three times as much ethene as VC (on a molar basis) was measured at three monitoring wells downgradient of the injection wells (Figure 2). Four years after the bioaugmentation, DHC BAV1 were found more than 350 feet downgradient from the injection wells, at densities of 104 to 105 cells per milliliter (mL). Overall results of the pilot-scale test and aquifer tracer tests indicated that effective full-scale treatment of the plume could likely be achieved with injection wells on 15-foot centers in rows 150 feet apart across the plume axis.

Figure 2. Pilot-test averages for three monitoring wells located 25-75 feet downgradient of injection wells.

Treatability testing was designed and implemented based on the pilot results. In 2010, 78 injection wells were installed in seven rows across the plume to target all zones containing TCE and breakdown products at concentrations exceeding maximum contaminant levels (MCLs) (Figure 1). A total of 134 injection intervals were achieved with 10-foot-long nested shallow and deep screens (25 and 40 feet below ground surface [bgs], respectively) in 56 of the wells.

A total of 955,000 gallons of donor fluid was injected during three events in 2011 and 2012 (Figure 3). The fluid consisted of an emulsion of tap water and LactOil™ donor substrate containing slow-release soybean oil and fast-release ethyl lactate at concentrations similar to those used successfully in the pilot test. For cost savings and ease of handling, the substrate was purchased in bulk quantity and delivered in 10 tank trucks carrying a total of 53,000 gallons (461,000 pounds). The donor fluid was batch-mixed with tap water onsite in temporary 6,500-gallon tanks. To expedite injection, a manifold was constructed to meter emulsion flow to six wells simultaneously. Each injection event lasted approximately two months, with events starting about six months apart.

Figure 3. Electron donor injection to multiple wells within a row.

Treatability study bioaugmentation was conducted concurrent with the second biostimulation (donor) injection, using groundwater extracted from the pilot area as inoculum. The groundwater inoculum contained DHC BAV1 at densities exceeding 104 cells/mL (lower than the 106 cells/mL common in commercially available inocula) and was used in agreement with the pilot test inoculum vendor. To prevent DHC mortality caused by contact with dissolved oxygen, donor solution was biologically reduced prior to injection by adding a concentrated anaerobic culture grown from site groundwater and storing the mixture overnight in a separate tank. The solution was injected immediately before and after the groundwater inoculum injection.

Aquifer chemistry and weather conditions presented challenges for plume treatment. Donor addition to a sand aquifer with low buffering capacity reduced the pH to below optimal conditions necessary for bioactivity, resulting in decreased ethane production. Low pH was addressed by using lower donor concentrations for the third injection. Also, thickening and some separation of the concentrated donor substrate occurred at low winter temperatures (<20°F) during the first injection. This problem was avoided during the third injection by storing deliveries of hot (up to 140°C) substrate in an insulated tank and optimizing delivery timing for immediate use. Lastly, some surfacing of injection fluid was observed during winter injection in areas with groundwater less than 1 foot bgs; this was addressed by injecting donor solution at a slower rate in these wells and shifting part of the injection volume to adjacent wells.

Groundwater monitoring is performed quarterly to semiannually. Analytical parameters include total organic carbon; aquifer redox; TCE and its breakdown products and end products; and microbial DNA analysis via quantified polymerase chain reaction (qPCR), including functional gene analysis. Monitoring results show that breakdown product cis-DCE has replaced TCE in predominance at most wells upgradient of the former pilot area. At a representative upgradient monitoring well, TCE decreased from 110 to 7 µg/L while cis-DCE increased from 26 to 590 µg/L, and a low level (1.5 µg/L) of ethene was detected. End products ethene and ethane are now the only compounds detected within the farthest upgradient injection row, indicating complete dechlorination in the immediate vicinity of bioaugmented wells. Although the number and extent of DHC BAV1 in upgradient areas have not yet increased substantially, an increase is anticipated over time.

Downgradient of the pilot area, TCE and cis-DCE concentrations have decreased to below MCLs (5 µg/L and 70 µg/L, respectively) and VC, ethene, and ethane predominate. At the plume's leading edge, VC concentrations are below the MCL of 2 µg/L. These results indicate complete dechlorination within the treatment zone, with no migration of TCE or breakdown products to wells beyond the treatment area.

Additional donor injection may be needed as electron donor is consumed, but further bioaugmentation injection is not anticipated. The cost to plan, implement, and monitor this treatability test (excluding earlier pilot testing) over the first three years was approximately $1.4 million. This includes $640,000 to purchase the donor substrate and $192,000 to construct the 78 injection and seven additional monitoring wells, representing a cost of $5.25 per cubic yard of the target treatment zone.

Full-Scale Application: Source Area Biostimulation Combined with a Biobarrier

Contributed by Greg Gilmore, Georgia Environmental Protection Division; Kevin Morris, ERM

A full-scale approach for stimulating indigenous microbes to achieve anaerobic reductive dechlorination of trichloroethene (TCE) in groundwater was implemented recently at Rummel Fibre, an industrial facility in northern Georgia. The biostimulation design involved source-area treatment to address elevated TCE concentrations remaining after ex situ groundwater treatment and a permeable injection biobarrier to mitigate offsite migration of dissolved-phase TCE. Results to date indicate that injection of a vegetable oil substrate is significantly accelerating the site's cleanup closure.

Soil and groundwater contamination at this 30-acre site resulted from TCE releases that occurred between 1970 and 1980 during manufacturing operations. Site lithology comprises silty saprolite overlying bedrock at 25 to 70 feet below ground surface (bgs). A 1993 investigation revealed TCE impacts to perched groundwater in the shallow (10-15 bgs) saprolite and some impact to groundwater in fractured bedrock. The highest identified TCE concentration in groundwater was 78,000 µg/L. Groundwater seepage velocity in this area is estimated at 90 feet per year but varies seasonally. A naturally occurring drainage swale bisects the source area. Prior to bioremediation, cleanup strategies included 1998-2002 operation of a groundwater pump-and-treat system followed by an in situ electro-chemical geo-oxidation (ECGO) system that began treating soil in 2003.

Initial biostimulation involved an onsite pilot study that used biotraps to collect data on the indigenous microbial community. Analysis of biotraps deployed in site groundwater revealed a healthy population of Dehalococcoides ethenogenes. Based on this finding, a small-scale substrate injection test was conducted in 2006. Test results indicated that complete reductive dechlorination of TCE could be achieved by using a commercially available substrate containing emulsified soybean oil (NewmanZone™). Monitoring indicated subsurface reducing conditions that persisted for nearly five years after the small injection, with no detection of TCE or evidence of contaminant rebound. For the past two years, biodegradation daughter products cis-dichloroethene, vinyl chloride, ethane, and ethane in the pilot test area have remained below maximum contaminant levels (MCLs).

In preparation for full-scale biostimulation, 70 injection wells were installed in December 2008. Thirty-five injection points were constructed at a spacing of 15 feet in the approximate 150- by 120-foot TCE source area. The injection points were installed through 20 to 50 feet of saprolite overburden to the top of bedrock. To create the permeable biobarrier that intersects groundwater flowing downgradient of the primary source area, an additional 35 injection points were installed at the same spacing over a linear distance of approximately 500 feet. The barrier injection points also were installed to the top of bedrock.

Figure 1. Delivery of substrate from a single 500-gallon tank into four injection points via a positive displacement pump.

In January and February 2009, the emulsified vegetable oil solution was injected into each point at a rate of 2-4 gallons per minute under a pressure below 30 pounds per square inch gauge (Figure 1). This low flow and pressure helped minimize potential short-circuiting to the ground surface (daylighting). Using a manifold system, up to four points were injected simultaneously. Substrate injections were conducted in the barrier line first to assure that a treatment zone was established prior to injecting into the source area.

The total combined injection volume for all 70 injection points was 98,000 gallons of solution containing 95,000 gallons of water and 3,000 gallons of the substrate. A total of approximately 7,000 gallons (100 gallons per point) of chase water was injected immediately after the substrate injection to assure that biofouling did not become a problem in the event additional injections are necessary. Since onsite groundwater is generally more compatible with indigenous anaerobic microorganisms, the water needed to administer the injection consisted of groundwater that was pumped from an onsite bedrock well and mixed with hydrant water.

Intermittent freezing temperatures during the full-scale injection caused some difficulty in handling the water, pumps, and hoses. Also, some daylighting occurred, primarily in the shallowest (<20 feet bgs) injection points. Any point displaying visual sign of daylighting was immediately valved off to minimize the amount of substrate escaping to ground surface.

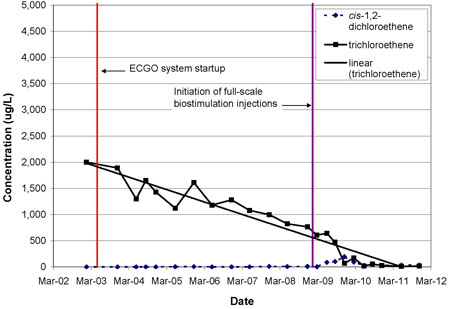

Figure 2. Average TCE concentrations in source area groundwater before and after vegetable oil injection.

Post-injection monitoring in the source area showed evidence of reductive dechlorination within three months (Figure 2), with dissolved oxygen below 0.5 mg/L and pH maintained at about 6.5. Within six months, TCE concentrations had decreased from the pre-injection average of 3,000 µg/L to below the MCL of 5 µg/L. Reductive dechlorination end products ethene and ethane have been detected at concentrations reaching 200 µg/L, with an average concentration of approximately 100 �g/L in the source area. This represents a significant increase from the highest concentrations of ethane and ethane prior to full-scale biostimulation, which were below 1 µg/L.

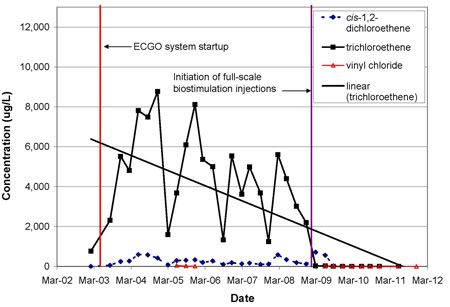

Monitoring of overburden groundwater downgradient of the permeable barrier shows similar trends (Figure 3). Reducing conditions were observed in the groundwater within six months after injection completion. Within nine months, ethane and ethane were detected for the first time in two downgradient wells. Currently, these downgradient locations show an average TCE concentration of 40 µg/L, the lowest concentration in nearly 20 years.

Figure 3. Average TCE concentrations in groundwater downgradient of the biobarrier before and after vegetable oil injection.

The ECGO system was shut down in 2010, following 12 months of evidence that anaerobic reductive dechlorination continued to occur in the source area and downgradient groundwater. Due to overall success of the biostimulation, the Georgia Environmental Protection Division (GAEPD) has agreed to modify the monitoring program from a quarterly to a semi-annual schedule.

The approximate costs to implement full-scale bioremediation at this site currently total $575,000. This includes $35,000 to purchase the electron-donor substrate, $260,000 to install the 70 injection points and administer the injections over two months, and $280,000 for four years of monitoring. Currently, the GAEPD is considering a two-year monitored natural attenuation as a final remedy. Cleanup closure is anticipated in 2015-2016, approximately 20 years ahead of original estimates.

RESOURCES

CLU-IN Website: Bioremediation of Chlorinated Solvents

This remediation technology area of CLU-IN provides an overview and compendium of reference materials, application reports, and other information resources on in situ and ex situ methods of using bioremediation.

Upcoming Report: Superfund Remedy Report (14th edition)

EPA's Office of Superfund Remediation and Technology Innovation anticipates release of the 14th edition of this report in January 2013. The report presents an analysis of Superfund remedial actions documented in records of decision (ROD), ROD amendments, and explanations of significant differences for fiscal year (FY) 2005 through FY 2012 and identifies general trends in Superfund remedy selection over the past 20 years. Information compiled for the 13th edition revealed that 61% of the remedies selected for in situ treatment of groundwater in FY 2005 through FY 2008 involved bioremediation.

ESTCP Cost & Performance Report: Application of Nucleic Acid-Based Tools for Monitoring Monitored Natural Attenuation (MNA), Biostimulation and Bioaugmentation at Chlorinated Solvent Sites

This report (ER-200518) from the U.S. Department of Defense Environmental Security Technology Certification Program provides results from a recent project that: demonstrates correlations between dechlorination of chlorinated ethenes and the presence and abundance of Dehalococcoides sp. biomarker genes; defines limitations of the deoxyribonucleic acid biomarker-based approach and specifies conditions where quantitative real-time polymerase chain reaction (qPCR) assay offers or fails to provide meaningful information; and develops a guidance protocol for practitioners to apply this tool.

A Citizen's Guide: Bioremediation

As one of a 22-document series, this two-page fact sheet answers general questions about using bioremediation for contaminated site cleanup. The 2012 update to "A Citizen's Guide to Bioremediation" (EPA 542-F-12-003) explains how bioremediation works and aspects such as typical duration, safety, and benefits of this technology. Other topics addressed in the citizen's guide series include pump and treat, in situ chemical oxidation, evapotranspiration covers, fracturing for site cleanup, and vapor intrusion mitigation.

Upcoming Training: Low-Cost Remediation Strategies for Contaminated Soil and Groundwater

The National Groundwater Association offers this three-day course on February 6-8, 2013, in Denver, Colorado, to help participants select a remedial technology for a site and determine how to properly design, install, and monitor the technology. Technologies covered in this course include enhanced bioremediation, air sparging, phytoremediation, and natural attenuation for remediation of contaminated groundwater, bioventing for remediation of contaminated soil, and bioslurping for removal of light non-aqueous phase liquids.

Conference Proceedings: 5th International Symposium on Biosorption and Bioremediation

Proceedings from the 5th International Symposium on Biosorption and Bioremediation held in Prague this past June are now available online from the Institute of Chemical Technology. Topics addressed at this conference include biodegradation of recalcitrant organic compounds, phytoremediation, heavy metal sorption, use of genetically modified organisms, and microbial ecology in contaminated environments. The National Technical Library of the Czech Republic and the non-profit European Federation of Biotechnology are among the event sponsors.

Contact Us:

Suggestions for articles in upcoming issues of Technology News and Trends may be submitted to

Linda Fiedler via email at fiedler.linda@epa.gov.

Past Issues:

Past issues of the newsletter are available at http://www.clu-in.org/products/newsltrs/tnandt/.

Archives | Subscribe | Change Your Address | Unsubscribe