This issue of Technology News and Trends looks back to find lessons learned from projects described in earlier issues of the newsletter.

Chitin Emplaced Using Hydraulic Fracturing Enhances Bioremediation of Ground Water

CLU-IN Resources

The Technology Innovation News Survey (TINS) contains market and commercialization information; reports on demonstrations, feasibility studies, and research; and other technology development news of interest to the hazardous waste community. To browse the TINS archives or subscribe to bimonthly updates, visit http://clu-in.org/products/tins/.

Following a successful pilot-scale field test in 2002, full-scale application of “biofracing” was conducted over a 26-month period in 2003-2005 to remove chlorinated solvents from ground water at the Distler Brickyard Superfund site near West Point, KY. (For information on site conditions and details concerning the pilot, see the January 2003 issue of Technology News and Trends.) A natural biopolymer derived from shrimp and crab shells, chitin was injected into a tight aquifer using hydraulic fracturing to provide a source of volatile fatty acids (VFAs) that served as electron donors for anaerobic reductive dechlorination (ARD). The full-scale results continued to show that the technology effectively delivered chitin within the site’s low-permeability subsurface, generated highly reducing geochemical conditions, and significantly stimulated natural biodegradation of chloroethenes.

The full-scale test application was designed to further evaluate the effectiveness and longevity of chitin-stimulated biodegradation in the field and to concurrently evaluate the performance of various grades of chitin under laboratory conditions. Using techniques similar to those of the pilot test, a larger network of 33 hydraulic fractures was initiated from 10 direct push holes within an expanded (0.4-acre) treatment area. Approximately 4,800 pounds of chitin were mixed with sand in a guar slurry and injected into the aquifer, creating hydraulic fractures that extend 15-20 feet through the area’s fine-textured sediment.

Monitoring focused on VFA concentrations, redox indicators, and concentrations of trichloroethene (TCE) and its degradation products in ground water. Visual examination of soil cores helped to document the fracture network geometry and evaluate changes in chitin over time.

Soil cores collected one week after chitin emplacement showed that the location of chitin- and sand-filled fractures highly corresponded to locations inferred by inverse modeling of data obtained from a network of tiltmeters. Visual examination of a second set of core samples collected eight months later showed that chitin degradation was accompanied by development of strongly reducing conditions. Sediment near the fractures had changed in color from tan to dark gray, and the presence of a black precipitate (likely a sulfide mineral) was observed in the fractures. These changes suggest that the strongly reducing conditions needed for ARD to occur were generated near chitin-filled fractures.

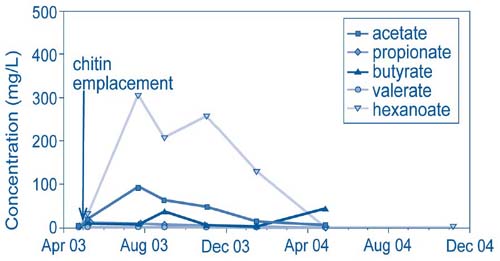

Ten rounds of ground-water monitoring data demonstrated that VFA production began almost immediately after chitin emplacement and continued over the following year (Figure 1). Total VFA concentrations one week after chitin emplacement ranged from 8.4 to 5,020 mg/L, with a median concentration of 109 mg/L.

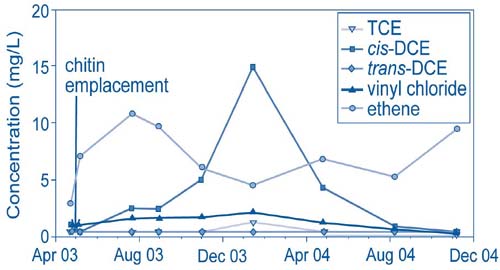

VFA production was accompanied by development of strongly reducing conditions, as indicated by lower sulfate concentrations and higher methane concentrations. Production of the highest concentration of methane (25 mg/L) occurred approximately eight months after the chitin was emplaced, when maximum cis-dichloroethene (DCE) concentrations also were observed. Overall, increased concentrations of cis-1,2 DCE and ethene (Figure 2) show that biodegradation of TCE was significantly stimulated by chitin emplacement. Concentrations of ethane, as a final TCE degradation product, peaked nearly four months after chitin placement and remained elevated to various degrees throughout the project period.

Concurrent laboratory column studies were conducted at Pennsylvania State University to compare VFA production, chloroethene degradation, and chitin longevity for three grades of chitin (SC-20, SC-40, and SC-80). While the most refined grade of chitin (SC-80) demonstrated superior performance in terms of VFA production and chloroethene degradation, the least refined grade (SC-20) performed nearly as well. The intermediate refined grade (SC-40) performed slightly lower. Based on these results and an estimated factor of 2.5 cost differential between the SC-20 and SC-80, researchers recommend the use of SC-20 in future applications.

Full-scale biofracing at this site was estimated to cost $500,000, which was provided by the National Science Foundation under an innovative technology grant for small businesses. It is estimated that chitin accounted for only 2.5% of the total project cost. Other agency support was provided by the U.S. EPA Region 4, which provided analytical services. The State of Kentucky, now holding lead responsibility for cleanup at the Distler Brickyard, anticipates that ground-water monitoring will continue for several years until cleanup goals are met.

Contributed by Ken Logsdon, Kentucky Department for Environmental Protection (502-564-6716 or kenneth.logsdon@ky.gov), Femi Akindele, U.S. EPA Region 4 (404-562-8809 or akindele.femi@epa.gov), and Bob Starr, North Wind, Inc. (208-557-7878 or bstarr@northwind-inc.com)

Continued Triad Approach for NAPL Removal Expedites Fort Lewis Cleanup

Aggressive treatment of a nonaqueous-phase liquid (NAPL) source area at the Fort Lewis Logistics Center near Tacoma, WA, was undertaken last year following use of a Triad approach for characterizing contaminant migration in the area’s dual aquifer system. In 2002, the Fort Lewis Public Works and U.S. Army Corps of Engineers (USACE) had completed site characterization involving a dynamic investigation approach, systematic planning, and real-time data collection (described in the July 2004 issue of Technology News and Trends). They then installed and operated an in-situ electrical resistance heating (ERH) system to sequentially treat three NAPL source areas of the logistics center’s “East Gate Disposal Yard.”

The Triad approach was continued during the remediation stage to maximize removal of NAPL containing TCE and associated volatile organic compounds (VOCs) from soil and ground water at the first of the three source areas. Sequential treatment will allow lessons learned from one source area to be applied to the next through an adaptive site management approach. In the first treatment area, an onsite gas chromatograph/mass spectrometer (GC/MS) and other field-based technologies such as vibrating-wire transducers were used during ERH operations. Such onsite methods facilitate a dynamic strategy for measuring contaminant recovery rates and mass, ensuring hydraulic containment goals are met, modifying the treatment system as needed, and optimizing the treatment system’s efficiency.

In the first treatment area, heat was applied across a 25,500-ft² zone using 106 electrodes installed at depths extending 39 feet below grade. Each electrode contained a co-located multiphase extraction well that was plumbed to other electrode wells, resulting in six separate liquid and vapor recovery regions. The system’s original operational requirements included a constant temperature of 100°C in the saturated zone, 90°C in the vadose zone soil, and sustained temperatures at these levels for 60 days. Temperatures during system operations were monitored with 224 thermocouples.

During active treatment, the onsite GC/MS produced water and air data within 24 hours of sample collection and the data were posted to an online system accessible by all project staff. A total of 870 air samples and 858 water samples were analyzed. Offsite laboratories analyzed split samples and selected primary samples, including 58 air samples and 46 water samples.

Monitoring indicated that the goal of sustaining a boiling temperature throughout the entire saturated zone for 60 days was unnecessary due to diminishing return of chlorinated solvent mass recovery. The conceptual site model consequently was refined to reflect a better understanding of contaminant distribution. After three months of ERH operation, the remediation strategy was modified to focus on maintaining 100°C in smaller areas where evidence of NAPL was noted during pre-remediation sampling and system installation.

The presence of NAPL had been identified earlier through use of photoionization and ultraviolet methods, sheen tests, and specialized soil test kits. This information was used during ERH operations alongside wellhead-specific vapor data to determine which multi-phase extraction wells were producing the largest mass of contaminant and to direct electrical power toward those areas.

Approximately 95% of the thermocouples reached the TCE boiling point (77-89°C) below the ground-water table, and 86% reached the project’s target temperatures. Failure to achieve the desired temperatures at 31 of the thermocouples was attributed to an unexpected presence of distinct, highly permeable paleochannels at depths of 16-21 feet, which introduced steady streams of cold water. Thermocouples that reached the TCE boiling point were maintained an average of 97 days. Those that reached project target temperatures were maintained an average of 70 days.

Temperature data also were used to determine the point of system shutdown, which occurred after eight months of operation. At that point, temperatures in the NAPL hot spots had been maintained above the boiling point of TCE in water for an average of 97 days. Subsurface temperatures at 193 of the 224 thermocouples had reached 90°C in the vadose zone and 100°C in the saturated zone, and subsurface VOC concentrations had decreased more than 90%.

Ground-water quality data from wells inside, outside, and below the treatment area have not indicated contaminant rebound within the treatment area following shutdown of the ERH system. Similarly, contaminant migration beyond the treatment area after shutdown has not been observed.

Use of ERH resulted in a total mass removal (including vapors, dissolved-phase liquid, and NAPL) of 2,576 kg of TCE, 405 kg of DCE, and 40,171 kg of total petroleum hydrocarbons. Vapor data indicated that recovery of vapor-phase TCE peaked approximately four months after system start-up. At the same time, ground-water data showed that TCE concentrations peaked as NAPL transitioned to the dissolved phase. TCE concentrations dropped over the following four months to levels below starting concentrations (averaging 383 µg/L). These estimates do not include degradation occuring in-situ during treatment.

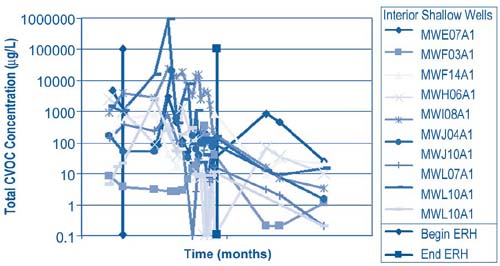

Data from nine ground-water monitoring wells showed significant reductions in chlorinated VOC concentrations following ERH treatment (Figure 3). The highest ground-water concentration of TCE prior to treatment was 1,500 µg/L. Though it increased to a maximum of 950,000 µg/L during heating, the average concentration decreased to 57 µg/L and is expected to continue declining. Post-treatment monitoring confirms that no contaminant rebound has occurred in saturated or vadose zone soil, and that significant TCE NAPL no longer exists in the treatment area.

The Triad work strategy is being modified as lessons are learned throughout the remediation process. Cleanup at the second source area recently began, and remediation of the third area is scheduled to begin in the spring of 2006. Optimization of the site’s existing pump-and-treat system will continue for removal of remaining dissolved-phase contaminants from the ground water. A detailed technical profile on this and other Triad projects is available from the on-line Triad Resource Center at https://triadcentral.clu-in.org.

Fort Lewis currently is designing and implementing an area-wide treatment performance assessment to evaluate thermal treatment system impacts on contaminant flux. In addition, an Environmental Security Technology Certification Program (ESTCP) demonstration is underway to evaluate bioremediation and enhanced mass transfer for dense nonaqueous-phase liquid (DNAPL) source treatment.

Contributed by Kira Lynch, USACE (206-764-6918 or kira.p.lynch@nws02.usace.army.mil)

Field Tests Show Enhanced Bioremediation following Cyclodextrin Flushing

The U.S. Department of Defense (DOD) conducted a four-month field demonstration in 2002 to evaluate cyclodextrin-enhanced in-situ removal of organic contaminants from ground water at the Naval Amphibious Base Little Creek in Virginia Beach, VA (see January 2003 Technology News and Trends). Under its ESTCP, DOD more recently analyzed the project’s cost and performance data. They found that TCE concentrations in DNAPL declined an average of 77.3% from pre-treatment levels; initial aqueous TCE concentrations increased nine-fold; and solubility for 1,1,1-trichloroethane (TCA) increased up to 19-fold. Overall DNAPL saturation in the treatment wells decreased 70-81%.

The cost of cyclodextrin-enhanced flushing (CDEF) was evaluated based on two deployment methods: injection and extraction (I/E) of cyclodextrin solution using several wells, and application of cyclodextrin in a multi-well push-pull (CPPT) mode. The CPPT approach cost approximately half of a comparable I/E system. While the cost of full-scale implementation of CDEF was found to be similar to other technologies, significant cost savings are associated with CDEF due to its ability to shorten remediation time.

Researchers concluded that the use of other technologies may be required in conjunction with CDEF at some sites, such as those involving free-moving NAPL. In addition, CDEF may be most effective in initially lowering extremely elevated concentrations of contaminant, followed by a remediation approach to further reduce concentrations to below MCLs. (The complete ESTCP cost and performance report [publication number CU-0113] is available at http://www.estcp.org)

CDEF technology was used more recently at a former dry cleaning site in Denver, CO, as part of a voluntary cleanup and brownfield redevelopment effort. Enhanced reductive dechlorination (ERD) was implemented at this site through a series of molasses injections into a subsurface comprising relatively tight sand, clay, and silt. These conditions required hydraulic fracturing to enhance ground-water flow and ensure delivery of the carbohydrate material needed for anaerobic microbial degradation. Through a network of 65 borings, 119 fractures at depths of 12-37 feet were initiated over the extent of a ground-water plume of tetrachlorethene (PCE) exceeding 5 mg/L. A mixture of sand, guar gum, and chemical stabilizers was introduced into the subsurface during hydrofracturing to create highly permeable fractures in each of the two water-bearing zones. The hydraulic radius of influence for these fractures ranged from less than 5 to 75 feet.

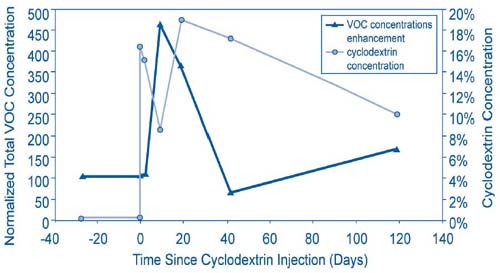

Once data confirmed the ERD system was mature, a pilot-scale CDEF test was conducted to evaluate the use of cyclodextrin to enhance chlorinated VOC (CVOC) desorption from soil while acting as a carbohydrate source to stimulate the reductive dechlorination process. The area’s downgradient dissolved-phase plume was already being treated using an in-situ reactive zone (IRZ) strategy. In this “inject-leave” application, any CVOC mobilization in ground water resulting from cyclodextrin injection would be treated in the downgradient IRZ. Preliminary results suggest that cyclodextrin increased the aqueous-phase concentration of total CVOCs at this site by approximately 350% (Figure 4).

A follow-up pilot study is underway at a second commercial site in Colorado where mixed solvents (including 1,1,1-TCA, TCE, methylene chloride, and petroleum distillates) had leaked from underground storage tanks. The study is further evaluating the effectiveness of using cyclodextrin in a push-pull application to remove DNAPL and to lower source area concentrations to levels eventually treatable by natural attenuation. In contrast to conventional application based on a “line-drive” hydraulic strategy involving multiple injection wells and distant extraction wells, the push-pull strategy allows cyclodextrin solution to be injected into a single treatment well and extracted from the same well after a short residence time. The push-pull method avoids high rates of agent dilution (up to 90%) that are common to the line-drive method as well as the extensive ground-water flow modeling required for line-drive implementation. In addition, operational costs are lowered by the use of only a single well and by the conservation of costly but recyclable cyclodextrin agent.

Contributed by Assoc. Prof. Thomas Boving, University of Rhode Island Department of Geosciences (401-874-7053 or boving@uri.edu), Craig Divine, Ph.D., ARCADIS G&M (720-344-3500 or cdivine@arcadis-us.com) and Juli Park, ARCADIS G&M (720-344-3500 or jpark@arcadis-us.com)

“Supermulch” Amendment Expedites Revegetation at Mining Sites

In 1997, the U.S. Department of Agriculture (USDA) and University of Washington began conducting a series of revegetation experiments and demonstrations at the Bunker Hill Mining and Metallurgical (Superfund) Site in central Idaho (detailed in the July 2003 Technology News and Trends). A mixture of municipal biosolids and wood ash, called “Supermulch,” was applied to an approximate seven-acre ground surface encompassing a former impoundment and hillsides surrounding a former zinc smelter. Through a unique partnership, amendment materials for a portion of the hillside remediation were provided by the City of Coeur d’Alene and Avista Utilities. The project’s innovative technical and business strategies merited an award of engineering excellence from the American Council of Engineering Companies earlier this year.

Long-term monitoring indicated that tissue samples from plants grown in the Supermulch remained within normal ranges and that revegetation was achieved on 100% of the amended plots. For example, zinc concentrations in soil of the amended plots ranged from 2,500 to 19,000 ppm, while zinc concentrations in plant tissue ranged from 45 to 74 ppm–well within normal plant concentrations. Analysis of seed germination as another key index of revegetation showed that no germination had occurred during the same time in control plots.

The revegetation approach developed at Bunker Hill has since been employed at other sites. In 1998, University of Washington researchers assisted EPA’s Environmental Response Team (ERT) in designing an amendment mixture for alluvial tailings deposits at the California Gulch Superfund site in Leadville, CO. Disposal or erosion of high-pyrite tailings into the Arkansas River over the past 100 years had created a 10-mile stretch of barren mine deposits with high acidity and elevated metal concentrations in soil, including 1,500-3,500 ppm lead, 9-27 ppm cadmium, and 1,500-3,400 ppm zinc. In addition, high metal concentrations in irrigated pastures had contributed to elevated rates of plant toxicity and high mortality in grazing livestock. Removal of the tailings was not feasible due to the potential for tailings to enter the river during field activities, the high cost of replacement topsoil, and the difficulty of locating an acceptable repository for contaminated soil.

The Bunker Hill revegetation strategy was modified at California Gulch to use higher rates of lime amendment to neutralize the acidity of the tailings, and to apply the Supermulch amendment directly into (rather than atop) the tailings at a depth of 6-12 inches using a bulldozer and toothed ripper. Inexpensive biosolids again were obtained partially through a municipal partnership, with Denver Metro, the public wastewater treatment authority in Denver, CO.

Seven years later, approximately 35 acres of the ten-mile riverside stretch have been restored and now support dense vegetation (subject to recent drought conditions). Analytical sampling conducted by EPA and USDA indicates that although total soil concentrations of metals of concern have not changed, extractable and available lead, cadmium, and zinc are now below regulatory standards. For instance, toxicity characteristic leaching procedure (TCLP)-extractable cadmium in the top foot of soil decreased from 1.32 ppm in the untreated tailings to 0.06 ppm within two years after amendment addition.

ERT conducted a four-year ecological risk assessment of the treatment area, finding that metals-related risk to wildlife no longer exists. In addition to standard extracts such as TCLP and the multiple extraction procedure (MEP), the assessment evaluated ecosystem endpoints “from the soil up,” including microbial populations and activity in soil; earthworm communities and metal uptake; plant germination and metal concentration; field plant species diversity; small mammal populations and metal body burden; and fat head minnow survival in re-entrained tailings of the upper Arkansas River. The evaluation found that biosolids and lime amendment had reduced metal toxicity sufficiently to restore ecosystem function for all endpoints, as highlighted by key findings:

- Microbial function in the biosolids-amended tailings (as measured by carbon dioxide evolution) in the first year after amendment addition was 10 times higher than in untreated tailings and four times higher than in uncontaminated soil.

- Earthworm survival averaged 80% in the treated tailings, as compared to 1992-2000 tests showing 0% in the untreated tailings and 99% in the laboratory control soil.

- Small mammal populations were similar to those in offsite regions, and laboratory analysis of small mammal target organs showed no signs of malfunction or damage.

Superfund Turns 25

This year marks the 25th anniversary of the Superfund program. To commemorate this milestone, the U.S. EPA is developing a series of oral and photo projects covering Superfund history, its social complexity, and important events, and will launch a national discussion of the program's changing nature. Information on participation in these projects or future viewing of the anniversary documentation is available at http://epa.gov/superfund/25anniversary .

As a result of Supermulch amendment, cattle-grazing has resumed on land that was barren for more than 80 years, and a public park with a fishing area now operates on one of the former tailings deposits. Similar results have been observed after this technology was initiated at the Oronogo Duenweg Mining Belt site in Jasper County, MO, in 1999-2001. The approach now is under evaluation for use at a wetland tailings repository at the Bunker Hill site and at alluvial tailings deposits outside of Prescott, AZ.

Contributed by Sally Brown, University of Washington (206-616-1299 or slb@u.washington.edu) and Harry Compton, U.S. EPA- ERT (732-321-6751 or compton.harry@epa.gov)