Green Remediation Focus

Pharmacia & Upjohn Company LLC Site

North Haven, Connecticut

RCRA Corrective Action

Image Gallery

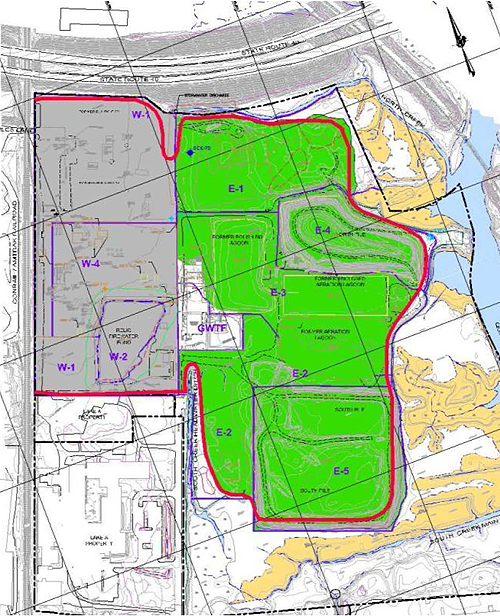

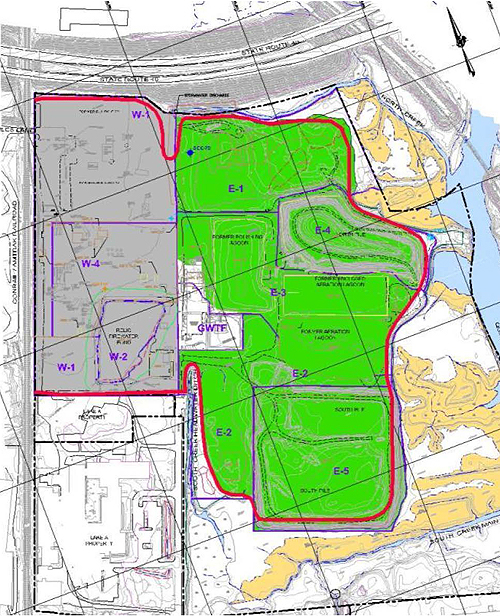

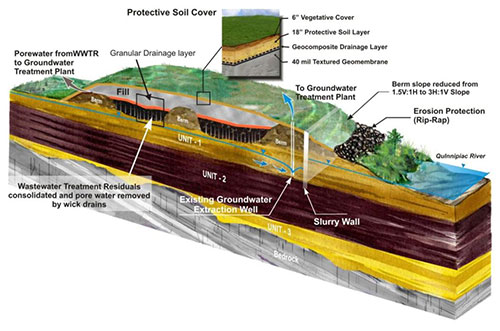

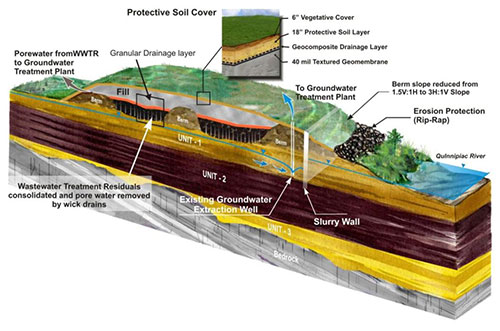

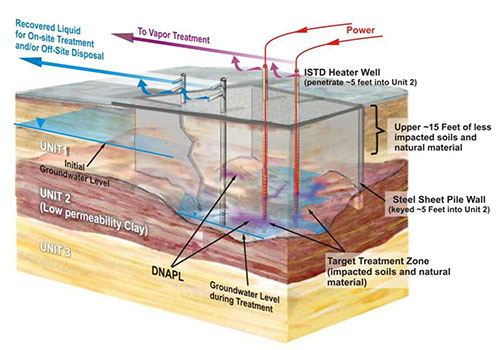

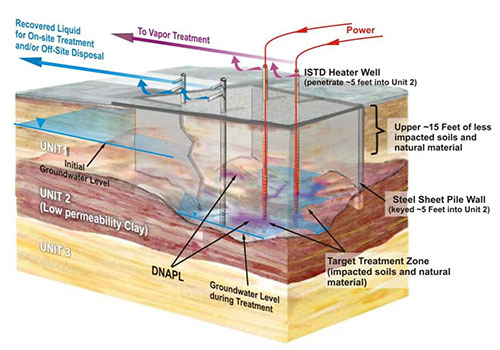

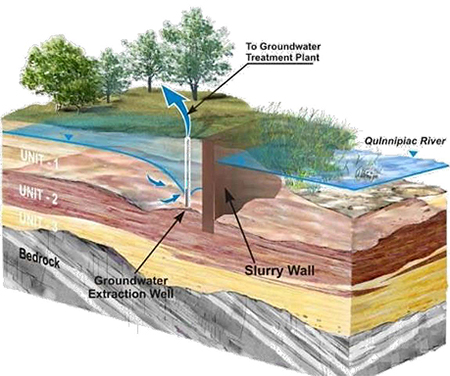

Cleanup Objectives: Provide long-term protection of human health and the environment by remediating soil, sediment and groundwater impacted by past releases of manufacturing wastes, wastewater and wastewater treatment residuals, including contaminants such as volatile organic compounds, polychlorinated biphenyls and lead. A corrective action interim measure involved constructing and operating a groundwater pump-and-treat (P&T) system. The final corrective action involved an upgrade of the P&T system, installation of a perimeter hydraulic barrier wall, excavation and onsite consolidation of impacted soils, construction of low-permeability soil cover systems, in situ thermal remediation (ISTR) to remove dense non-aqueous phase liquids (DNAPL), sediment dredging in tidal wetlands, extensive ecological restoration, and preparation of a portion of the site for future redevelopment opportunities. The 78-acre site is located along the Quinnipiac River, approximately eight miles from the Atlantic coastline of the Long Island Sound.

Green Remediation Strategy:

The strategy involved: (1) conducting a quantitative analysis of the carbon footprint of remedial activities and identifying opportunities to reduce the footprint; (2) incorporating green remediation best management practices (BMPs) during remedy construction; (3) revitalizing the site's ecological systems in a manner that complements the Quinnipiac River ecosystem; and (4) integrating the community's vision for future use. Key studies and findings affecting the strategy included:

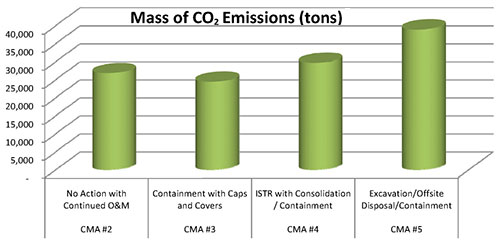

- Results of the quantitative assessment of carbon dioxide (CO2) emissions of corrective measure alternatives. The assessment focused on emissions associated with:

- Transportation of materials required for remedy construction.

- Major energy use relating to treatment or offsite transportation and disposal activities.

- Long-term operation and maintenance (O&M).

- Results of a corrective measure study, including the carbon footprint analysis, which found that:

- A reduction in the rate of contaminated groundwater extraction could be realized by adding low-permeability cover systems to prevent stormwater infiltration and a perimeter hydraulic barrier wall to limit the influence of the Quinnipiac River on groundwater levels.

- Energy usage for treating the extracted groundwater could be significantly decreased by reducing the rate of groundwater extraction.

- Reuse of onsite soil, sediment and debris as fill beneath constructed cover systems could significantly reduce the volume of clean soil/fill requiring import to the site.

- ISTR operations could be optimized by identifying, in the pilot study phase, the most effective heating temperatures to achieve a balance of energy input (and associated CO2 emissions) versus mass removal rates.

The ASTM Standard Guide for Greener Cleanups (E2893-13) was used to formally document the BMPs and to monitor the environmental footprint reductions achievable or gained by incorporating the BMPs into design and implementation of the final corrective action. A total of 129 identified BMPs potentially applied to the site. In accordance with the standard guide, the applicable BMPs were assigned priorities of high, medium or low and further evaluated to identify influencing factors such as implementation ease or cost.

The final BMP implementation plan, as documented in a site-specific greener cleanup technical summary![]() , reflected more than 80 BMPs including 8 for site assessment, 26 for the P&T system, 9 for sediment dredging, 22 for the cover systems and 18 for the ISTR system. Due to the site's proximity to Long Island Sound, design of the remedy also considered climate change impacts such as 500-year flood events and rising sea levels that may affect long-term remedy implementation. In 2016, the project merited a GreenCircle Award from the Connecticut Department of Energy and Environmental Protection.

, reflected more than 80 BMPs including 8 for site assessment, 26 for the P&T system, 9 for sediment dredging, 22 for the cover systems and 18 for the ISTR system. Due to the site's proximity to Long Island Sound, design of the remedy also considered climate change impacts such as 500-year flood events and rising sea levels that may affect long-term remedy implementation. In 2016, the project merited a GreenCircle Award from the Connecticut Department of Energy and Environmental Protection.

Results:

- Minimizing the carbon footprint over the course of cleanup activities, with mass CO2 emissions estimated at:

- 3,270 tons for installation of all cap and cover systems.

- 5,950 tons for ISTR pilot study and full-scale implementation combined.

- 20,450 tons for 30-year long-term O&M.

- Optimizing the groundwater treatment train through intermittent modifications over time to reduce energy usage and improve treatment effectiveness. Upon optimization completion, it is estimated that energy usage will be reduced by 40 percent. Upcoming optimization measures include modifying the advanced oxidation component by replacing the UV-peroxide process with an ozone-peroxide process.

- Removed an estimated 26,000 to 41,000 pounds of contaminant mass from groundwater during pilot-scale ISTR operations in 2012, using a total of 1,122,000 kWh of energy. Although the system temperature peaked at 228°C, performance monitoring demonstrated that a temperature of 100°C was sufficient to meet performance standards while lowering energy expenditures.

- Removed an estimated 229,700 pounds of contaminant mass during full-scale ISTR operations in 2015-2016, using a total of 11,950,557 kWh of energy.

- Used solar-powered air monitoring equipment during both the pilot-scale ISTR and full-scale ISTR.

- Used the excavated sediment, drill cuttings and excess grading soil and debris as grading fill below three cover systems for residual waste, as an alternative to offsite disposal or importing fill.

- Used approximately 2,465 tons of ground, granulated blast furnace slag (a repurposed manufacturing byproduct) rather than bentonite (a natural resource) to construct the low-permeability hydraulic barrier wall, which surrounds approximately 80% of the site. Field tests indicated that a hydraulic barrier wall constructed with Portland cement/slag had a lower permeability than one constructed with Portland cement/bentonite.

- Optimized design of the groundwater monitoring well network through use of real-time data collection technologies such as a membrane interface probe. Downhole video imagery was used to confirm subsurface features and optimize installation of the monitoring wells.

- Reduced the rate of groundwater extraction from an average of 180,000 gallons per day to approximately 94,000 gallons per day by installing the hydraulic barrier wall and the low-permeability cover systems rather than relying on groundwater P&T alone. The groundwater is extracted from seven extraction wells and two groundwater collection trenches, treated at the onsite facility (currently via biological, chemical coagulation, UV oxidation and hydrogen peroxide processes) and discharged into the Quinnipiac River.

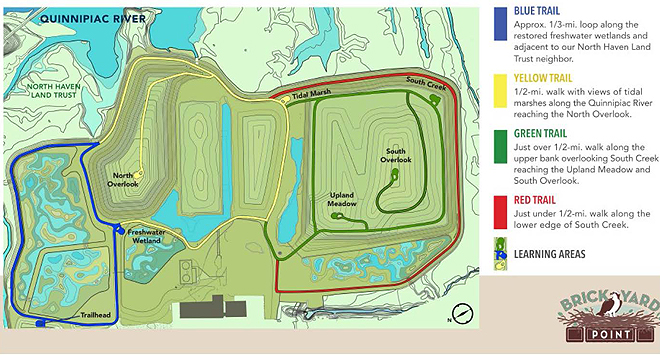

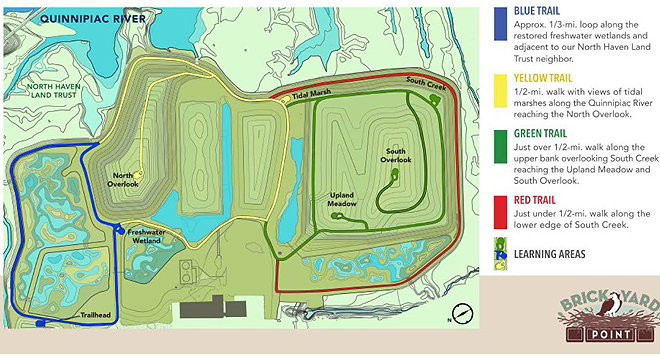

- Constructed 6 acres of onsite freshwater wetlands to store stormwater shed by the soil covers. The stormwater flows to the wetlands via natural gradients without active pumping. The constructed wetlands also provide critical habitat for freshwater plant and animal species.

- Selected shrub and grass species that are native to the region's upland meadows to revegetate the top layer of each cover system, the back-filled excavation areas and outlying disturbed land. Care of the meadows involves maintaining pedestrian or utility-vehicle traffic corridors, managing invasive species, and revegetating when needed.

- Sequestering atmospheric carbon on more than half of the 78-acre site through ongoing maintenance of vegetation in the wetlands and upland meadows.

- Established an onsite ecological preserve comprising about 60 acres of tidal marshes, inland wetlands and upland meadows. The preserve strengthens habitat linkages in the Quinnipiac River corridor, enhances local diversity of flora and fauna, and provides critical habitat for species such as osprey. As of June 2021, more than 45 different species of breeding birds were observed at the site.

- Gave preference to local sources of labor, services and materials to further reduce the project's offsite transportation-related footprint. During the corrective measures implementation, over 40% of the project's labor, services and materials were sourced within 25 miles of the site and over 55% were sourced within the State of Connecticut.

- Strengthened support for the remedy and long-term stewardship of the site by engaging local stakeholders in reuse planning, baseline ecological studies and post-remediation ecological restoration planning. Stakeholder groups included the North Haven Citizens' Advisory Panel, North Haven Trail Association, North Haven Land Trust, North Haven Open Space Advisory Committee and Quinnipiac River Watershed Association as well as academic institutions with environmental programs (such as the University of New Haven and the Yale School of Forestry and Environmental Science).

- Conducting long-term O&M and monitoring of the site remedy through a stewardship permit issued by the Connecticut Department of Energy and Environmental Protection in 2021. The permit ensures continued remedy protectiveness of human health and the environment while allowing potential future use of the west-side development area.

Property End Use: Approximately two-thirds of the property has been restored as an ecological preserve with restored habitat and an interpretive trail system for restricted public access and environmental education. Seventeen acres adjacent to an existing commuter rail line are available for potential commercial, light industrial or transit-oriented uses.

Point of Contact: Juan Perez, U.S. Environmental Protection Agency Region 1; Craig Bobrowiecki, Connecticut Department of Energy and Environmental Protection; and Russell Downey or Tom Donohue, Pfizer Inc.

Update: August 2021