Green Remediation Focus

Whitney Young Branch Library

Chicago, Illinois

Brownfield

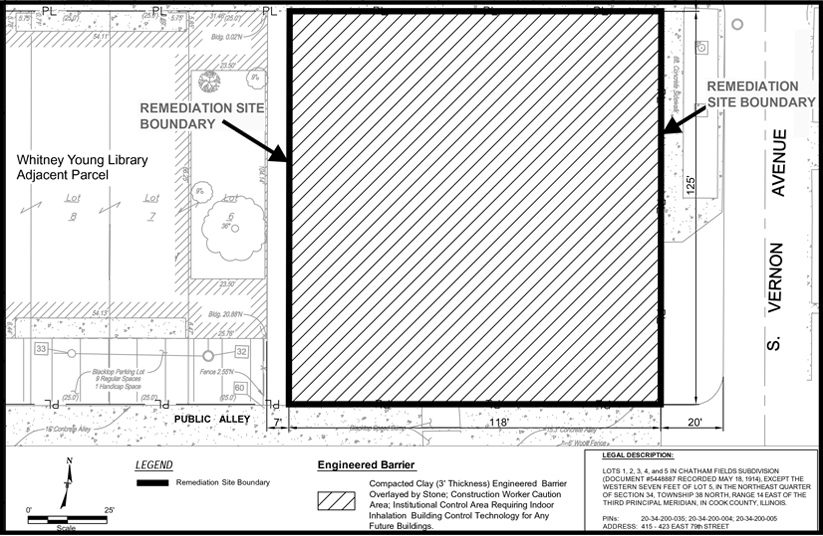

Cleanup Objectives: Remediate a 0.34-acre urban site with soil and groundwater contaminated by tetrachloroethylene and associated degradation products due to past use of the site for purposes such as drycleaning and auto repair. The site encompasses three municipally-owned parcels adjacent to an operating public library.

Green Remediation Strategy: Applied the ASTM Standard Guide for Greener Cleanups (E2893-13) to identify best management practices (BMPs) for reducing the remediation project's environmental footprint, as part of the Sustainable Chicago initiative. Implementation of the strategy, which merited a 2014 Environmental Stewardship Award for Environmental Excellence from the National Association of Environmental Professionals and a 2015 Illinois Governor's Sustainability Award, reduced the originally estimated cleanup cost ($4.9 million) by nearly 50% due to minimized soil excavation and disposal.

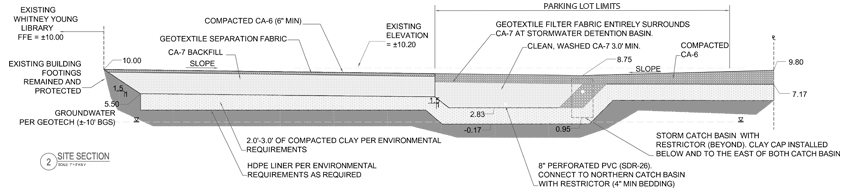

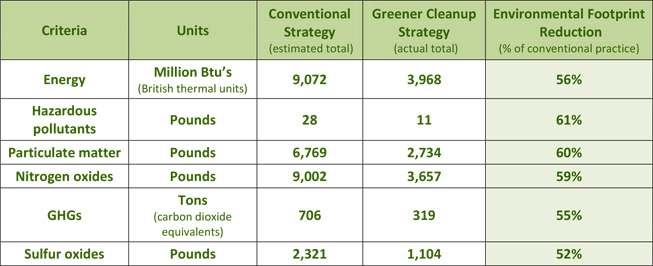

Application of the ASTM standard guide included quantitative evaluations of a greener cleanup strategy and a conventional strategy through use of the U.S. Environmental Protection Agency's Spreadsheets for Environmental Footprint Analysis (SEFA). The implemented greener cleanup approach involved excavation and disposal of upper layers of soil; in situ chemical oxidation (ISCO) to address contaminant hot spots in deeper layers; and installation of a site-wide engineered horizontal barrier consisting of a lined, compacted clay cap supported by a stormwater detention area and drainage system. Institutional controls prohibiting onsite installation of potable water supply wells remain in place to prevent exposure to residual contamination in the groundwater, and long-term groundwater monitoring is underway to determine if downgradient wells are negatively impacted.

Through use of the ASTM standard guide, the following prioritized BMPs were selected for implementation during remedy design and construction; collectively, the BMPs addressed all five core elements of a greener cleanup.

High Priority BMPs

- Establish a clearly defined target treatment zone (TTZ) and associated performance standards that help avoid unnecessary resource consumption and land disturbance.

- Link remediation activities to site development and construction to maximize opportunities for material reuse and minimize transportation-related footprints.

- Use local staff, including subcontractors, when possible to minimize transportation-related resource consumption.

Medium Priority BMPs

- Mix amendments (chemical reagents) into soil in situ rather than ex situ to minimize dust generation and air emissions associated with double handling of material.

- Implement an engine idle reduction plan for machinery and equipment operating during demolition and construction.

- Salvage uncontaminated objects and infrastructure components with the potential for recycle, resale, donation or reuse.

- Use well drilling methods, such as direct-push technology, that minimize land disturbance and the volume of drill cuttings requiring disposal.

- Use a local analytical laboratory to minimize transportation-related footprints associated with shipment of soil and water samples.

Results:

Energy Conservation

- Reduced overall consumption of energy, primarily in the form of diesel fuel, during remedy construction by approximately 56% due to clear definition of the TTZ and associated reductions in soil excavation and disposal.

- Minimized onsite use of diesel fuel by implementing an idle reduction plan. The plan was adopted from Chicago Municipal Code 9-80-095, which limits engine running in any standing diesel fuel-powered motor vehicle to no more than a total of three minutes within any sixty-minute period.

- Minimized offsite use of gasoline through procurement of workers living in proximity to the site. In accordance with the cleanup service contract negotiated by the Public Building Commission of Chicago, approximately 21% of the project employees resided within a one-mile radius of the site, which also minimized the project's footprint concerning road congestion. The average one-way commuting distance was 15 miles.

Air & Atmosphere

- Reduced total onsite and offsite air emissions by 52-61% through incorporation of in situ remediation technologies when compared to the alternative remedy exclusively involving contaminated soil excavation and offsite disposal. The emission reductions addressed hazardous pollutants (61% reduction), particulate matter (60%), nitrogen oxides (59%), greenhouse gases (55%) and sulfur oxides (52%).

- Reduced onsite emissions from machinery by minimizing double-handling of ISCO materials. Trench boxes to be used for chemical reagent mixing were installed within rather than adjacent to areas undergoing treatment. After reagent mixing was complete, removal of the frame around each trench allowed the mixture to be readily combined with clean soil during backfilling.

- Reduced offsite air emissions associated with material shipping by procuring analytical services from the closest commercial laboratory, which was located approximately 12 miles from the site.

Water Conservation

- Minimized the need for potable water during ISCO activities through in situ mixing of the chemical reagents (including sodium percarbonate and hydrogen peroxide) with clean soil instead of delivering the reagents through a slurry process.

- Minimized the need for dust-suppression spray water by utilizing chemical reagents in a dry crystalline form rather than powder form. Less than 2,000 gallons of water was needed to suppress dust during reagent spreading in the ISCO treatment areas.

- Designed and installed a remedial drainage system, including a stormwater retention area, that can be integrated with other structures during future site redevelopment to divert stormwater from the municipal sewage system.

Materials & Waste Management

- Diverted approximately 22,000 cubic yards of material from the regional hazardous waste (RCRA Subtitle C) landfill by using ISCO rather than excavation to address contaminated soil at depths of 8 to 14 feet below ground surface. The nearest hazardous waste landfill is located 250 miles from the site.

- Recycled approximately 480 tons of concrete accumulated during onsite demolition. The uncontaminated concrete rubble was hauled to any of three recycling plants located an average distance of 13.5 miles from the site.

- Recycled 0.76 tons of demolition-associated metal at a recycling center located approximately eight miles from the site. Additionally, the steel used to form the ISCO trench boxes was salvaged after reagent mixing and re-used as shoring below a sidewalk and street along the site perimeter.

- Used approximately 4,000 tons of compacted stone aggregate rather than clean soil as backfill above the clay cap in an effort to integrate site remediation components with anticipated site redevelopment needs. The stone aggregate provides a more suitable ground surface on which to construct buildings, parking lots or other structures and supporting infrastructure.

Land & Ecosystems Protection

- Minimized surface and subsurface disturbance through use of Geoprobe® equipment to advance 65 borings for sampling in unsaturated and saturated zones at multiple depths. When compared to alternative use of hollow stem auger methods, deployment of this direct-push equipment also generated less investigation-derived waste, streamlined investigation activities, and minimized visual disturbance at the site's urban setting.

- Delineated in detail the extent of site contamination, to target contaminant hot spots and minimize the size of areas requiring ISCO treatment. Based on the delineation, design of the engineered horizontal barrier involved an alternative 3-foot compacted clay cap barrier with an HDPE bottom liner that excludes the outdoor inhalation exposure route and allowed for shallower excavation requirements when compared to the Illinois Environmental Protection Agency's standard 10-foot-deep barrier. During construction, this design helped reduce material use as well as the number of truck trips to and from the site, thereby minimizing related traffic congestion, air emissions, noise and community disruption.

- Minimized potential disturbance of the clay cap or additional soil handling during future site redevelopment by installing the clay cap at an elevation lower than potential utility structures.

Property End Use: Future development by the City of Chicago or a private owner

Point of Contact: LeeAnn Tomas-Foster, Public Building Commission of Chicago

Update: October 2015