Green Remediation Focus

Re-Solve, Inc.

North Dartmouth, Massachusetts

Superfund NPL

Cleanup Objectives: Remediate soil, sediment and groundwater contaminated by waste oils, volatile organic compounds (VOCs), polychlorinated biphenyls (PCBs), lead and other hazardous materials from past use of the site for waste chemical reclamations. Distillation tower residues, liquid sludge waste, impure solvents and burned tires were disposed of in four unlined lagoons on this six-acre site. Additionally, oil waste was spread throughout the site to control dust and disposed of onsite through land farming.

Green Remediation Strategy: The strategy currently focuses on a groundwater treatment approach that minimizes energy usage, carbon emissions, chemical and other product usage, residual waste generation, and offsite disposal of contaminated or spent materials. Previously, the strategy also strived to minimize fossil fuel and other energy consumption associated with remediating areas containing PCB-contaminated soil and sediment and to enhance the site's ecosystem services. Implemented best management practices include:

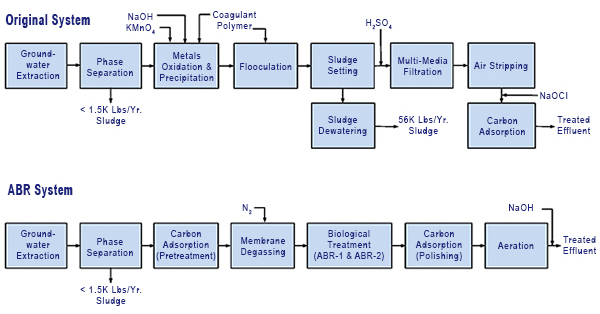

- Optimizing the site's pump and treat (P&T) system periodically. Upon 1998 start-up, the system employed metals separation, air stripping and catalytic oxidation processes. Integration of an anaerobic bioreactor (ABR) near the onsite groundwater treatment plant enabled 2012 shut-down of the energy- and material-intensive air stripping and catalytic oxidation processes.

- Installing an onsite renewable energy system to power cleanup activities. A 150-kilowatt photovoltaic (PV) system connected to the local electricity grid began operating concurrent to the bioreactor start-up. Details about these and other environmentally sustainable aspects of the groundwater remediation system and its infrastructure are documented in a site-specific report, Sustainability Enhancements Performance Report: Management of Migration Groundwater Extraction and Treatment System.

- Treating excavated soil and sediment onsite rather than transferring the soil/sediment to an offsite hazardous waste facility for disposal and treatment.

- Avoiding use of potentially toxic chemicals to treat extracted groundwater. The optimized P&T system's ABR beds contain a highly organic and environmentally friendly sand-peat mixture that promotes VOC degradation by naturally occurring microorganisms.

- Restoring onsite wetlands to their natural conditions after land-disturbing remediation activities such as soil or sediment excavation are complete.

- Creating new habitat for wildlife in upland areas disturbed by remediation activities.

- Forming partnerships among the cleanup stakeholders to restore and monitor affected ecosystems and nearby surface water. Partners include the U.S. Environmental Protection Agency, U.S. Fish and Wildlife Service, and potentially responsible parties comprising the ReSolve Site Group.

Results:

Energy Use & Air Emissions

- Minimized fuel consumption and associated emissions involved in transferring PCB-related waste to an offsite facility for disposal; the nearest TSCA-permitted hazardous waste facility is located approximately 750 miles from the site. The low-temperature desorption techniques used to treat soil and sediment onsite generated only a small volume of desorbed liquid waste requiring offsite disposal, which avoided disposal of all excavated soil and sediment (36,000 and 3,000 cubic yards, respectfully) if not treated onsite. Additional offsite energy and emission reductions were gained through this approach due to its avoidance of high-temperature incineration techniques used by the offsite disposal facility to destroy PCB waste.

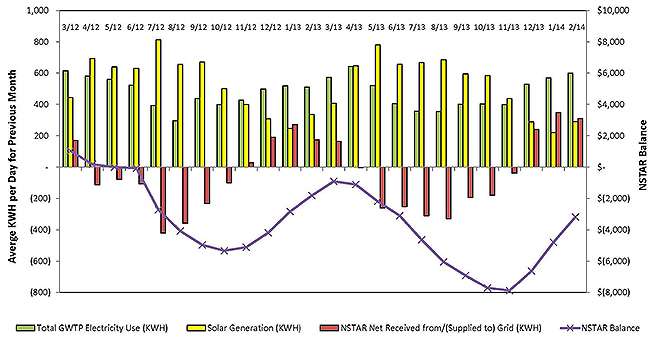

- Reduced the net amount of grid electricity demanded by the P&T system by more than 100% through use of onsite solar energy. Excess electricity generated by the PV system is supplied to the local electricity grid through net metering; at night and other times when the PV system is not producing sufficient electricity to directly power the treatment plant, electricity is drawn from the grid.

- Reduced overall consumption of electricity to operate the P&T system by approximately 26%, from an average of approximately 242,000 kWh per year prior to August 2012 to approximately 179,000 kWh per year. This reduction is attributed to energy conservation measures such as: (1) eliminating certain motorized mixers within the influent equalization tank, flocculation tank and neutralization/filter feed tank; (2) replacing a 20 horsepower (HP) blower that drew air through the tank ventilation system (and former air stripper) with a 3 HP blower; and (3) reducing operating times of other equipment with high power motors. For example, a 15 HP air compressor that was previously used on a regular basis to power sludge processing and dewatering operations now operates infrequently. Similarly, the 15 HP filter backwash pumps for transferring service water had previously operated daily but are now used once every two months.

- Reduced the amount of propane annually consumed by the groundwater treatment system by approximately 95%. The formerly used catalytic oxidizer required approximately 20,000 gallons of propane each year. In contrast, the ABR system annually requires approximately 1,100 gallons of propane to heat the two subsurface ABR beds during cold months. The annual rate of propane consumption associated with heating the interior of the treatment plant remains at about 2,200 gallons.

- Eliminated the need for air emission treatment, which was required in the original groundwater treatment system involving air stripping. The currently used ABR is primarily a closed, passive treatment system relying on VOC degradation by anaerobic microorganisms as well as an ABR effluent polishing process involving VOC sorption in two granular activated carbon (GAC) beds equipped with passive air vents.

- Reduced the net subtotal mass of carbon dioxide (CO2) production associated with electricity generation and use by the groundwater remediation system, from approximately 342,000 pounds per year to an estimated negative of 4,100 pounds per year. About 26% of this reduction resulted from greater conservation of electricity at the treatment plant; the remaining 74% reduction is attributed to use of onsite solar energy.

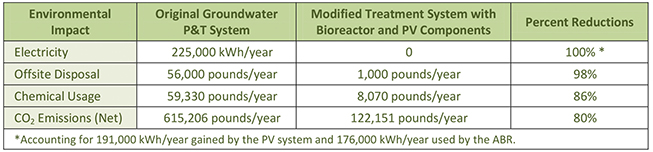

- Reduced the total carbon footprint of the P&T system by 80% through integration of the ABR and solar energy, from approximately 615,000 pounds of CO2 per year to approximately 122,000 pounds of CO2 per year. Footprint analysis of the solar energy system included onsite contributions associated with construction as well as offsite contributions associated with PV panel manufacturing.

Materials Consumption & Waste Generation

- Reduced the use of process chemicals by approximately 86% through integration of the ABR, from approximately 59,000 pounds each year to approximately 8,200 pounds of chemicals each year. Process chemicals no longer needed include sulfuric acid, potassium permanganate, aluminum chlorhydrate, sodium hypochlorite and polymers.

- Reduced the change-out volume of activated carbon (and its virgin coal-based content) needed to pretreat and polish the extracted groundwater, from approximately 10,000 pounds to an estimated average of 8,100 pounds per year. The activated carbon used over recent years consists of approximately 50% virgin carbon and 50% reactivated carbon, which have a carbon footprint estimated at 8.9 pounds and 1.1 pounds of CO2 produced per pound of activated carbon used/regenerated, respectfully. Use of coconut shell-based carbon, with a yet lower carbon footprint (estimated at 1 pound of CO2 per pound of activated carbon) is anticipated in the future.

- Reduced the volume of metal hydroxide sludge requiring offsite disposal by approximately 98%, from approximately 56,000 pounds per year prior to 2012 to approximately 1,000 pounds per year after integration of the ABR.

- Exploring future optimization steps to further reduce material as well as energy and water usage, such as identifying additional operating parameters (other than flow rates) that may be modified to reduce GAC change-out frequency in the pretreatment or polishing steps; operating the two ABR beds in parallel rather than a series; and operating the ABR at a lower temperature (below 55°F). Additionally, capture and onsite storage of rainwater that lands on the treatment building's roof may be used for site-wide cleaning purposes; currently, all water is delivered to the site by tanker truck.

Land & Ecosystems

- Restored one acre of onsite wetlands, most of which lie within the Copicut River 100-year floodplain.

- Converted four acres of the excavated/backfilled areas, which were covered with a gravel cap, into a native meadow that enhances local habitat and re-establishes native plant species needing little maintenance. In consultation with the U.S. Fish and Wildlife Service, the site owner installed elevated boxes and sand or brush piles to further enhance bird, turtle and other wildlife habitat in the meadow. The enhancements also complement goals associated with 25 acres of adjacent land owned by the Dartmouth Natural Resource Trust.

- Engaging the community in long-term monitoring of nearby surface water through sponsorship of an annual fishing derby at the nearby Cornell Pond, where American eel, brown bullhead and yellow perch tissue had shown high PCB concentrations prior to site cleanup. The latest derby results suggest that surface water quality is significantly improved; for example, PCB concentrations in American eel tissue have decreased from 20 parts per million (ppm) prior to site remediation to below 1.0 ppm. The event also provides an opportunity to emphasize state strategies for aquatic species management.

- Treated over 410 million gallons of water since 1998 start-up of the P&T system. Annual operating costs for the P&T system decreased approximately 5% due to integration of the bioreactor and solar energy systems, from approximately $452,000 in 2012 to approximately $427,000 in 2013; additional cost reductions are expected over time due to future optimization efforts. Currently, approximately 18,000 gallons of water is treated annually.

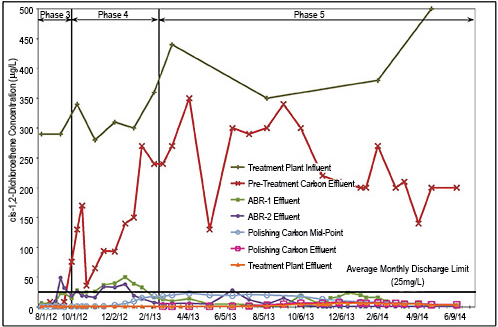

- Achieving effluent discharge standards consistently since 2012 startup of the ABR; all effluent is discharged via gravity to the Copicut River, which lies within the Buzzards Bay Watershed. One post-construction adjustment in process water management involved installing four degassing membrane contactors to remove dissolved gas from the ABR influent, which prevents accumulation of gas bubbles within the reactive media and consequently maintains efficient water flow through the ABR beds.

Property End Use: Natural resource conservation and restricted public use

Point of Contact: Joe LeMay, U.S. EPA Region 1

Update: February 2017