Green Remediation Focus

Elizabeth Mine

South Strafford, Vermont

Superfund Removal & NPL

Image Gallery

Cleanup Objectives: Remediate onsite soil and restore approximately five miles of water in adjacent and downstream surface waters negatively impacted by acid rock drainage, including the West Branch of the Ompompanoosuc River, Copperas Brook and Lord Brook. The acid rock drainage resulted from runoff passing through waste rock and tailing piles created by historic mining of iron sulfate and copper at this 250-acre site in east central Vermont.

Green Remediation Strategy: Reduce the environmental footprint of activities during excavation, waste consolidation and construction of a 45-acre capping system for 3 million cubic yards of tailings, with a focus on reducing greenhouse gas (GHG) emissions, using materials that are less toxic, and restoring the landscape and ecosystems in ways mirroring the surrounding area. Additional efforts aimed to minimize the energy-related footprint of treating the site's mining-influenced water. The strategy was developed in 2011 through a Superfund response action partnership among the U.S. Environmental Protection Agency (EPA) Region 1 office, U.S. Army Corps of Engineers (USACE), Vermont Department of Environmental Conservation (DEC), Nobis Engineering, Inc. and other partners. It involved best management practices (BMPs) addressing the five core elements of a greener cleanup and merited the project's receipt of a 2014 Green Dream Team Award under the USACE Sustainability Award Program.

BMPs used during cap construction, treatment of acid rock drainage and ongoing site management include:

- Using clean diesel technologies to reduce emission of GHGs, particulate matter and other air pollutants during heavy construction activities such as excavating waste rock, segregating and transferring soil for onsite consolidation and use, constructing surface water diversions, and installing distinct waste caps.

- Institutionalizing a project-level plan for fuel conservation.

- Using onsite renewable energy systems to directly power remedial or monitoring equipment.

- Transitioning from an energy-intensive active treatment system to a passive treatment system when key cleanup goals have been achieved.

- Choosing nature-based solutions to control stormwater runoff and provide resilience to potential flooding.

- Choosing manufactured products carrying EPA or U.S. Department of Agriculture verification as environmentally friendly or preferable materials.

- Using onsite resources rather than imported raw materials to generate borrow materials for cap construction.

- Adopting a project-wide program for recovering and recycling or re-using construction materials as well as routine consumer products.

- Restoring excavated/backfilled areas to more natural conditions by seeding with native plants that need little/no irrigation or other maintenance, attract pollinators, restore habitat for local and migratory wildlife, and sequester atmospheric carbon.

- Collaborating with local landowners and regional organizations on potential methods to mitigate adverse effects of cleanup activities on historic resources at the site.

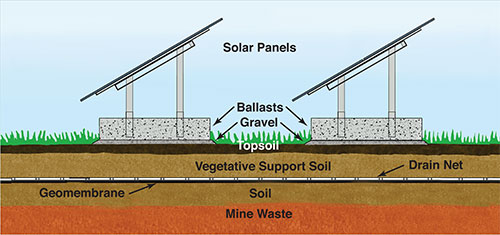

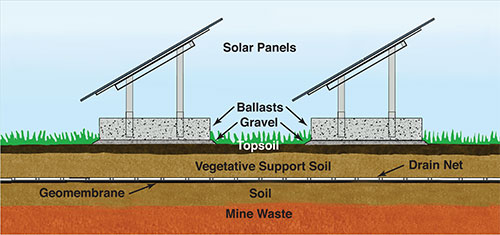

- Designing waste caps to be compatible with site reuse involving renewable energy development or creation of open space.

Results:

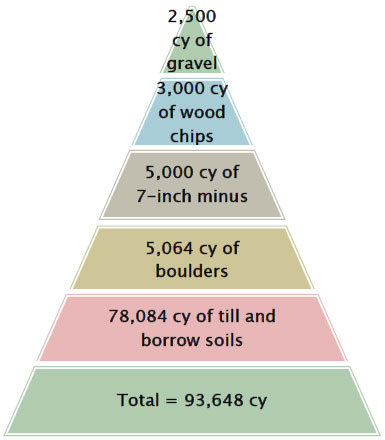

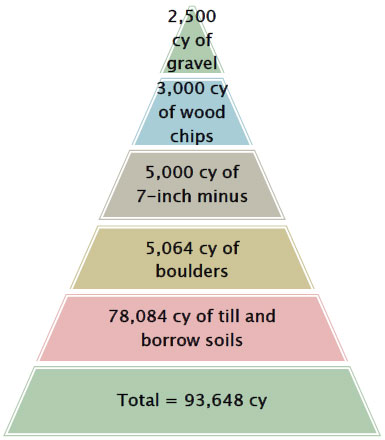

Air Quality Preservation

- Averted an estimated 1,899,000 pounds of carbon dioxide emissions by using three onsite areas covering a total of 12 acres to develop the natural resource (borrow) materials required for site preparation, cap construction and site restoration. Over two years, the areas produced nearly 174,400 cubic yards of earthen fill, including 165,000 cubic yards of till/soil and 9,400 cubic yards of boulders. The alternative of importing these materials was estimated to require more than 12,400 truck trips, each with a capacity of 15 cubic yards.

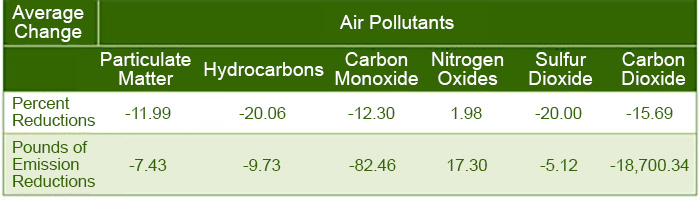

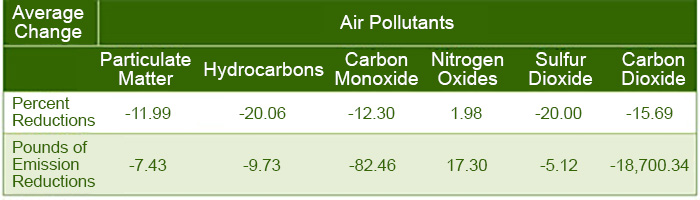

- Reduced onsite emission of air pollutants through use of biodiesel fuel (B-20). During six months of heavy construction in 2012, for example, use of 5,800 gallons of B-20 instead of conventional diesel fuel was estimated to reduce emission of particulate matter by 12 percent, hydrocarbons by 20 percent, carbon monoxide by 12 percent, sulfur dioxide by 20 percent and carbon dioxide by 16 percent.

- Reduced onsite emission of air pollutants through use of new excavators equipped with engines meeting Tier 4 standards during the same six-month period in 2012. When compared to older models, Tier 4 engines are estimated to reduce particulate matter emissions by 90 percent and nitrogen oxides by 50 percent and to improve fuel efficiency by 5 percent.

- Enabling offsets of carbon dioxide emissions through operation of a commercial 7.0 megawatt solar energy facility that was constructed on 27 acres of the capped areas. During its first year of operation (2017) the facility offset an estimated 7,136 tons of carbon dioxide emissions. The facility was developed through a partnership among Wolfe Energy, Brightfields and Greenwood Energy, with technical input from the U.S. EPA and Vermont DEC.

Energy/Fuel Efficiency & Conservation & Renewable Energy

- Minimized fuel consumption during remedy construction by equipping heavy machinery with diesel-electric power trains. Use of this technology on a bulldozer, for example, resulted in an estimated 30 percent decrease in fuel consumption and a 10 percent increase in production.

- Reduced onsite and offsite fuel consumption during remedy construction through implementation of a "zero idle" policy for field vehicles and machinery, facilitation of job-related carpooling among site personnel, and use of hybrid/economy vehicles wherever possible.

- Reduced energy usage for water treatment at a tailings area with an unstable dam (TA-1) through use a lime-based rotating cylinder treatment system™ (RCTS) to address high concentrations of ferrous iron in discharges from the tailings impoundment. Based on previous application elsewhere, the RCTS was anticipated to consume approximately 30 percent less electricity each day when compared to a conventional lime-based treatment system. Details about the system and its performance are available in EPA's summary report, Evaluation of Rotating Cylinder Treatment System at Elizabeth Mine

.

. - Avoiding long-term use of electricity to treat acid rock drainage in the vicinity of TA-1 by switching to a passive treatment system. The passive treatment system commenced after 10 years of RCTS operations, when construction of a cap for the TP-1 area was complete and the iron load in TP-1 leachate had significantly decreased (from a maximum of 800 pounds per day to an average of 24 pounds per day). The passive treatment system comprises an anoxic limestone drain, settling pond, vertical flow pond and polishing wetlands through which the leachate sequentially flows via gravity feed. Elimination of the RCTS reduced the site's annual maintenance costs by approximately $2,500.

- Reducing electricity consumption for long-term monitoring through use of small-scale solar energy systems that power equipment for water quality monitoring. In 2001 the U.S. Geological Survey installed five monitoring stations, each equipped with a data logger and cellular transmitter along with a 50-watt photovoltaic (PV) panel and 12-volt solar battery. During 2012 remedy construction, data loggers operating at other locations also were equipped with PV panels.

- Enabling an average of 8.7 million kilowatt-hours of electricity to be generated each year due to operation of the onsite solar energy facility. This amount of energy is equivalent to the electricity consumed by about 1,300 typical Vermont homes each year. The facility provides a tax revenue for the neighboring towns of Strafford and Thetford and helps defray Vermont DEC costs to maintain the waste caps for at least 25 years.

Water Quality Preservation & Water Resource Conservation

- Emplaced tubular devices (Filtrexx® SiltSoxx™) made of organic materials such as recycled compost on ground surfaces along the perimeter of the tailing piles during waste consolidation and cap construction, to control sediment and contain and filter stormwater. When compared to typical silt fencing that requires trench construction, performance monitoring over two years suggested the tubular system contained 50 percent more surface water runoff and sediment, returned more nutrients to the subsurface, and involved less maintenance.

- Used biodegradable rather than polyethylene sandbags in approximately 1,000 applications during cap construction to control stormwater runoff and prevent erosion in highly vulnerable areas adjacent to Copperas Brook.

- Converted two onsite sedimentation basins into permanent basins for stormwater detention or retention. The conversions involved excavating waste associated with former pit lakes near the site's "South Mine," emplacing native till/soil and topsoil, regrading to accommodate the site's natural drainage patterns, and installing rock-lined swales to slow and direct the flow of runoff entering the basin.

- Created an estimated 15.4 acres of clean, functional wetlands (a net increase of 6.9 acres) that provide the site with long-term stormwater filtration and absorption capacity. Approximately 8.5 acres of wetland areas filled with mine waste and containing water toxic to ecological receptors required removal.

Material Use & Waste Reduction

- Manufactured approximately 29,900 cubic yards of the required topsoil onsite, to minimize the offsite disturbance associated with using topsoil stripped from local sites. The topsoil consisted of 2 parts manure obtained from a local agricultural facility and combined with 2 parts woodchips and 3 parts soil available as byproducts from other onsite activities. The resulting blend contained more organic matter when compared to the region's typical montane topsoil, thereby providing more resistance to erosion and more nutrients for future vegetation.

- Contracted with a local agricultural facility to obtain the hay bales used as mulch in disturbed areas.

- Salvaged onsite wood debris for use in stabilizing steep slopes on relatively isolated portions of the site.

- Used weed-free pelletized mulch (EZ Mulch®) made from recycled newsprint and corn fiber to supplement seed establishment where needed.

- Reused approximately 1,000 cubic yards of temporary backfill soil at TP-4 as capping material for TP-1A.

- Salvaged approximately 3,139 cubic yards of 7-inch riprap that was used to stabilize slopes during construction of the stormwater basins, for immediate onsite use or stockpiling.

- Incorporated a product recycling evaluation into service procurements for remedy construction, which resulted in maximum recycling of construction materials. In 2011, for example, approximately 30 cubic yards of recyclable HDPE geomembrane liner and 96 HDPE liner cores (each 20 feet in length by 6 inches in width) were recycled.

- Initiated a project-wide consumable waste recycling program at the outset of cap construction. During 2012 remedy construction, for example, the program resulted in recycling of approximately 59 cubic feet of cans, 85 cubic feet of paper, 206 cubic feet of plastics, 35 cubic feet of glass and 167 cubic yards of scrap metal.

Land Conservation & Ecosystem Service Protection

- Protected the region's endangered bats by installing a bat grate at the mine's opening before beginning remedy construction.

- Used biodegradable, wood fiber-based material (Flexterra®) to create an erosion-control blanket on slopes adjacent to the completed TP-1A soil cap. The material fostered revegetation initiated by hydraulic seeding and avoided the hazards to wildlife sometimes posed by synthetic mesh blankets. It was blown onto target surfaces via a hand-held spray device deployed via minimal foot or truck traffic.

- Revegetated the newly created stormwater retention/detention basins by applying native seed mixes that targeted the State of Vermont conservation and wildlife goals. Additionally, native trees (red oak and sugar maples) were planted along the basin perimeters to provide woodland habitat and further aid stormwater management.

- Restored nearly 100 percent of the needed ground cover on the initial, 4-acre waste rock excavation area with tailing piles (TP-4) within three years. The selected seed mixes, which were applied on borrow soil by way of hand-broadcasting or drilling techniques, contained plant species that could thrive in the area's wet meadow and forest, help prevent erosion, create wildlife habitat and food sources, and offer grass and wildflower diversity.

- Created habitat for wetland species by planting approximately 3,000 trees and shrubs across the site's 15.4 acres of newly constructed wetlands. The overall gain in wetlands areas also increased the site's capacity to sequester atmospheric carbon.

- Salvaged two stable buildings and the foundations of other buildings during demolition of the former milling/smelting complex to accommodate the site's eligibility for the National Register of Historic Places. In accordance with a memorandum of agreement among the U.S. EPA, Vermont Division for Historic Preservation and Vermont DEC, archeological excavations were conducted prior to demolition to extract historic artifacts and document former workings of the complex. Related information is documented in a 2014 report, From Copperas to Cleanup: The History of Vermont's Elizabeth Copper Mine

.

.

Property End Use: Regional greenspace, environmental and historic education, and renewable energy development

Point of Contact: Ed Hathaway, U.S. EPA Region 1

Update: July 2022