- Featured Articles

- Energy & Air: Optimizing Energy Use and Using Renewable Energy

- Water: Stormwater Management Techniques for Greener Cleanup and Climate Change Resilience

- Materials, Waste and Ecosystems: Integrating Materials and Waste Management Plans with Ecosystem Protection

- Resources

- EPA Website: Greener Cleanups

- CLU-IN Website: Green Remediation Focus

- Industry Standard: ASTM Standard Guide for Greener Cleanups

- Updated Fact Sheet: Green Remediation Best Management Practices: An Overview

- Project Update: Greener Cleanup Bulletin: Use of the ASTM Standard Guide for Greener Cleanups at the North Ridge Estates Superfund Site

- Updated Planning Tool: Greener Cleanups Contracting and Administrative Toolkit

- New Analytical Tool: SEFA Tutorial

- Supporting Decision Tools: Updated Models, Calculators and Maps

Download This Issue in Adobe PDF® Format

Download This Issue in Adobe PDF® Format

(872KB/12pp/PDF)

Greener cleanup best management practices (BMPs) can reduce the environmental footprint of activities involved in remediating contaminated sites. Each feature article in this issue of Technology News & Trends provides site-specific examples of footprint reductions addressing one or more of the five core elements of a greener cleanup as outlined in the U.S. Environmental Protection Agency (EPA) Principles for Greener Cleanups. The articles also highlight quantitative and qualitative improvements in project outcomes as a result of implementing the BMPs.

The core elements of greener cleanups involve:

- Reducing total energy use and increasing the percentage from renewable energy.

- Reducing air pollutants and greenhouse gas (GHG) emissions.

- Reducing water use and negative impacts on water resources.

- Improving materials management and waste reduction.

- Protecting ecosystem services.

EPA and partnering federal and state agencies have begun integrating greener cleanup considerations into project documentation such as remedial designs and work plans. Additionally, the private sector increasingly reports that approaches for greener cleanups are incorporated in their standard operating procedures or corporate sustainability principles.

EPA offers a series of BMP fact sheets and the Methodology for Understanding and Reducing a Project's Environmental Footprint (EPA 542-R-12-002) to help plan and implement BMPs leading to a greener cleanup. ASTM International's Standard Guide for Greener Cleanups (E2893-13), which was developed through ASTM's consensus process, provides a more systematic approach to identifying environmental footprint contributions and identifying appropriate BMPs. For large or complex sites, cleanup stakeholders may opt to conduct a footprint analysis using the associated Spreadsheets for Environmental Footprint Analysis. A footprint analysis can quantify the footprint of potential, planned or implemented cleanup activities, including BMP benefits.

Energy & Air: Optimizing Energy Use and Using Renewable Energy

Contributed by Paul Peronard, U.S. EPA Region 8; LeeAnn Tomas-Foster, Public Building Commission of Chicago

Use of electricity and the burning of fossil fuel result in emission of pollutants such as greenhouse gases (GHGs) and particulate matter. Consumption of each gallon of diesel fuel (No. 1 or No. 2), for example, is estimated to emit approximately 22 pounds of carbon dioxide, and each kilowatt of electricity generated by a fossil fuel-powered plant generally results in approximately 1.5 pounds of GHG equivalent. Best management practices (BMPs) for reducing energy- and air-related footprints of cleanup activities often involve techniques and technologies that apply renewable energy or reduce the demand for energy, as illustrated at the Pennsylvania Mine site in Summit County, Colorado, and the Whitney Young Branch Library in Chicago, Illinois.

The U.S. Environmental Protection Agency (EPA) Region 8 office deployed a mobile solar unit for Superfund removal actions at the Pennsylvania Mine site near Keystone, Colorado, in 2014 and again in 2015. The unit was used to power equipment for support activities during construction of two concrete bulkheads that isolate contaminated water inside the mine. Isolation of the water reduces the amount of oxygen available to metals and sulfides and associated acid mine drainage to local surface water, such as the Snake River. In addition to reducing the project's consumption of diesel fuel and associated onsite emissions, this approach significantly reduced offsite emissions resulting from transport of greater volumes of fuel to this remote, mountainous site. Monitoring in October 2015, following September completion of the second bulkhead, indicated a 90% reduction in water exiting the mine.

Figure 1. Solar energy equipment supporting remedy construction at the Pennsylvania Mine.

Electricity generated by the mobile solar unit, a 25-kilowatt (kW) SolaRover Mojave 3 hybrid system (Figure 1), during both deployments powered a generator that recharged hand-held or portable tools and sampling devices and operated communication equipment, computers and heaters used by EPA's onsite field laboratory. The solar equipment consisted of a 4.5 kW solar array equipped with batteries capable of storing 80 kWh of electricity, along with multiple inverters for 2-50 amp, 220-volt circuits and 2-20 amp, 110-volt circuits. As a hybrid unit, the system included a 30 kW diesel generator. The unit was leased for $2,000 per month.

Use of the hybrid system in this off-grid setting provided continuous availability of power. The system was configured to deliver power only upon demand and to provide capability to handle variable loads during equipment use as well as surges due to equipment startup. Additionally, dedicated use of solar-generated electricity avoided harmonic distortion that is typical in diesel generators and requires buffering in applications involving sensitive electronics such as communication equipment and computers.

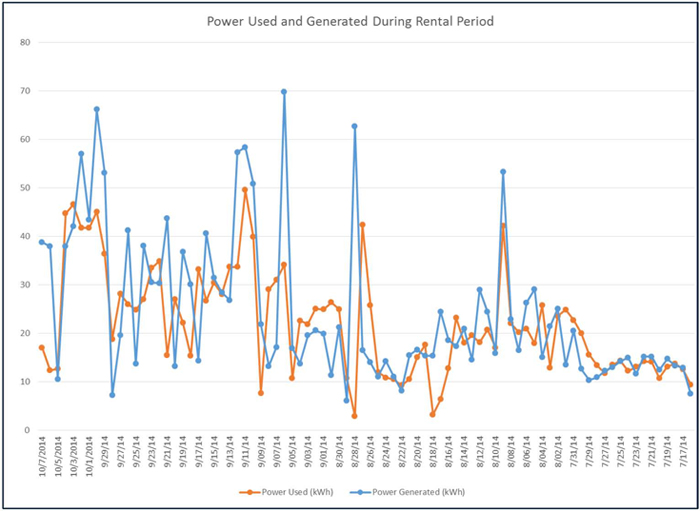

The vendor's analysis of energy data covering the 80 days of deployment in 2014 indicated that the solar component generated 1,200 kWh, approximately 58% of the power used onsite, at an efficiency of 97%. This amount of electricity otherwise produced by a fossil-fueled power plant would have resulted in an air-emission footprint estimated at 1,820 pounds of GHG equivalent. The analysis also suggested that the site's electricity demand (Figure 2) may have been met by a smaller hybrid power system. EPA and the Colorado Department of Mining and Remediation Services plan to install a third bulkhead in 2016.

Figure 2. Daily rates of power used and power generated by the integrated solar-diesel power system at the Pennsylvania Mine. (Note: The most recent date on the x-axis is to the left.)

At the Whitney Young Branch Library-Adjacent Site, a brownfield in Chicago, energy- and air-related footprints of site cleanup were reduced through advanced planning to conserve fuel during remediation. This 0.34-acre municipally-owned property, which sits adjacent to a public library, was contaminated by past site activities such as drycleaning and auto repair. The remediation involved excavating and disposing of shallow soil, implementing in situ chemical oxidation (ISCO) to address contaminant hot spots in deeper soil, and installing a site-wide engineered horizontal barrier consisting of a three-foot-deep compacted clay cap.

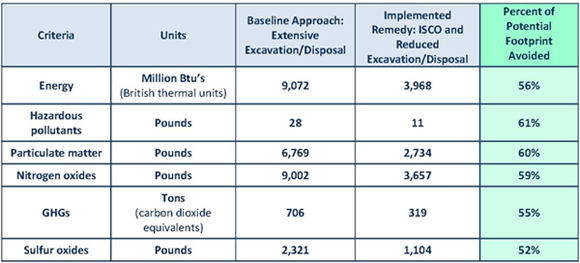

The Public Building Commission of Chicago (PBCC) used EPA's Methodology for Understanding and Reducing a Project's Environmental Footprint and companion Spreadsheets for Environmental Footprint Analysis (SEFA) to quantify the environmental footprint of the remedial action. To gain supplemental information, SEFA also was used to estimate the footprint reduction achieved through ISCO and reduced excavation and disposal. Analytical results indicated that the implemented remedial action reduced consumption of energy, primarily in the form of diesel fuel, by approximately 56% and generated 52-61% less air emissions (Figure 3).

Figure 3. SEFA-based footprint estimates of energy consumption and air emissions associated with the implemented remedy versus a baseline approach at the Whitney Young Branch Library; energy estimates include onsite and offsite uses and air emission estimates include onsite and offsite sources.

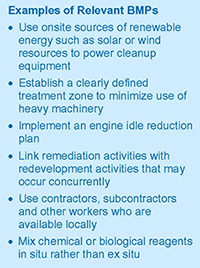

SEFA results indicated that the largest footprint contributions of the remedial action were: (1) the raw materials (virgin clay, sand and gravel) used to construct the engineered barrier; (2) fuel consumed while transporting these materials to the site, excavating, backfilling and grading soil, and disposing waste soil offsite; and (3) air emissions attributed to the onsite and offsite consumption of fuel. Through use of the ASTM Standard Guide for Greener Cleanups (E2893-13), best management practices (BMPs) were screened, prioritized and selected for implementation during remedy design and construction to address these footprint contributions.

High-priority BMPs concerning fuel consumption and associated air emissions included establishing clearly defined target treatment zones to minimize the need for heavy fuel-intensive machinery such as excavators. The project design also involved linking remediation with future site redevelopment activities to minimize fuel needed for installation of a stormwater vault, import or export of materials, and personnel transportation. Additionally, the service contract negotiated by the PBCC called for using local contractors and workers whenever possible, including subcontractors retained for drilling or for using direct-push technology to conduct soil sampling and chemical oxidant injections. Approximately 21% of the project employees resided within a one-mile radius of the site and the average one-way commuting distance for workers was 15 miles.

Medium-priority BMPs included mixing the ISCO reagents, which were procured from a local distributor, into soil in situ rather than ex situ to minimize dust generation and air emissions and to avoid double-handling of materials. The trench boxes needed for chemical reagent mixing were installed within rather than adjacent to areas undergoing treatment. Removal of the trench frames after mixing allowed the mixture to be readily combined with clean soil during backfilling and avoided the need for trench shoring and sheet piling.

Figure 4. Diesel equipment such as a 250-horsepower excavator and 100-horsepower soil compacting roller operated under an idle restriction plan at the Whitney Young Library site.

Other medium-priority BMPs involved implementing an engine idle reduction plan for machinery and equipment operating during demolition and construction (Figure 4) and using a local analytical laboratory to minimize offsite emissions associated with transporting soil and water samples. The idle reduction plan limited engine running in any standing diesel fuel-powered motor vehicle to no more than a total of three minutes within any 60-minute period. The commercial laboratory procured for analytical services was located only 12 miles from the site.

Cleanup costs for this property totaled approximately $2.6 million, about half of the estimated $4.9 million cost for site-wide excavation of contaminated soil and offsite disposal of contaminated soil. Implementation of this greener cleanup strategy, which was developed as part of the Sustainable Chicago initiative, merited a 2014 Environmental Stewardship Award for Environmental Excellence from the National Association of Environmental Professionals and a 2015 Illinois Governor's Sustainability Award.

Water: Stormwater Management Techniques for Greener Cleanup and Climate Change Resilience

Contributed by Karen Lumino, U.S. EPA Region 1; Lorraine LaFreniere, Argonne National Laboratory

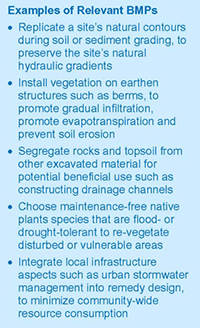

Addressing water aspects of a greener cleanup often includes best management practices (BMPs) aimed to establish or complement a green infrastructure, which uses a site's natural hydrologic features to manage water and provide environmental and community benefits. In addition to managing water as a valuable natural resource, the BMPs may help efforts to increase remedy resilience to potential climate change effects such as increased frequency or intensity of precipitation or sustained drought. For example, an evapotranspiration cover in California may need reassessment and possible modification if its original design reflected evapotranspiration rates no longer occurring due to recent drought conditions that increase susceptibility to plant and soil desiccation. Techniques for achieving a greener cleanup while preparing for increased precipitation are illustrated in stormwater management systems in place at the Pine Street Canal Superfund site and Murdock Groundwater Plume site.

Cleanup at the Pine Street Canal Superfund site in Burlington, Vermont, incorporates measures focused on water resource management and remedy protectiveness in light of potential inundation, extreme storm events, or ice buildup at and around the site's lengthy onsite canal. Remedial actions to address primarily coal gasification wastes have involved capping eight acres of contaminated sediments, installing a subsurface vertical barrier at the northwest corner of the site to prevent potential migration of contaminants into Lake Champlain (Figure 1), and restoring aquatic and wetland habitat. The site is hydraulically connected to Lake Champlain and vulnerable to flooding from the lake.

Figure 1. Aerial view of the 38-acre Pine Street Canal site, more than half of which is located in a 100-year-floodplain (primarily in vegetated areas).

Greener cleanup BMPs included installing two retention basins as a low-impact development approach to regulating stormwater flow where municipal storm sewers discharge to the canal. The basins are integral to the site's wetlands, which cover approximately 21 acres, and are designed to accommodate a flow equivalent to 150% of a 100-year storm event. Municipal stormwater enters the site through a 48-inch pipe and is directed through a series of engineered structures that begins with a channel that is lined with stone in submerged portions to prevent scour due to high flow velocity and ice buildup. The channel culminates at a distribution forebay where larger sediment is deposited; a riprap level berm spreader in the forebay reduces erosive energy of concentrated flow. Water passes from the forebay to a relatively wide wetlands area from which it discharges via an outlet pipe to a lower plunge pool. Water surface elevation in the outlet plunge pool is maintained at 96 feet above mean sea level by use of a 6-foot-diameter drop inlet structure connected to a 48-inch culvert extending under an adjacent street.

The street and surrounding neighborhood are additionally protected by emergency overflow berms, which were constructed of sand and topsoil removed during excavation of areas undergoing sediment cap installation. Similarly, rocks of various sizes were stockpiled during excavation for later use in lining the forebay channel and plunge-pool apron. Treatment efficiency of the stormwater controls was evaluated by using a typical urban runoff water quality and a 90th percentile annual rainfall event (0.9 inches). Evaluation results indicated 94-98% efficiency in removal of stormwater contaminants from the site's stormflow. [For comprehensive information about numeric performance or design standards applying to municipal storm sewer systems under the National Pollutant Discharge Elimination System, see the Environmental Protection Agency's (EPA's) Post-Construction Performance Standards & Water Quality-Based Requirements compendium.]

"Soft" engineered structures were constructed along the canal to increase site-wide resilience to climate change hazards such as inundation and soil erosion. Gabions were installed at certain locations of the canal bed to stabilize banks where emergent plants and willow were planted. Along the plantings, coir logs (made of flexible, biodegradable coconut husk fiber) were emplaced for additional erosion protection. Over time, the gabions additionally filled with silt serving as a substrate for growing submergent vegetation.

Figure 2. 50-foot weir at the Pine Street Canal outlet.

A weir (Figure 2) was constructed at the canal's outlet to Lake Champlain to maintain wetland water levels and prevent erosion of the cap due to storms as well as potential failure in a resident beaver dam. The weir was designed to maintain a minimum water depth of 96 feet, thereby protecting the emplaced subaqueous cap from scour, wave action and erosion. The weir also was designed to mirror the site's natural contours and withstand worst-case ice forces and 100-year (magnitude 4.0) earthquakes. Other design aspects included incorporation of removable stop logs and a six-foot-wide sluice intended to accommodate long-term variation in the canal stage elevation and to improve wetlands hydrology, optimize onsite wetlands functions, and improve access conditions for cap maintenance activities. The weir also was designed to accommodate the existing local infrastructure, which includes railroad tracks and a municipal bike path.

Restoration of the onsite wetlands to pre-remediation size, form and function was critical due to their ability to filter stormwater inflow as well as outflow before reaching capped portions of the site, in addition to their role in local stormwater management. BMPs for wetland and upland restoration included soil and sediment grading to return the shoreline to a more gradual slope conducive to waterfowl habitat and passage of other animals. Additionally, plant selection focused on choosing native species that could survive most readily; planted species particularly tolerant of flood conditions include giant bur-reed (Sparganium eurycarpum), speckled alder shrubs (Alnus rugosa), and black willow and green ash trees (Salix nigra and Fraxinus pennsylvanica). As part of restoring the wetlands wildlife habitat, a baffler (water bypass) was installed at the beaver dam existing near the canal outlet weir to support the beaver community while preventing back-up of the municipal stormwater collection system or localized erosion due to dam failure. EPA and the Vermont Department of Environmental Conservation will continue to require biweekly inspections during each field season (April through November) as part of long-term monitoring.

At the Murdock Groundwater Contamination site in eastern Nebraska, Superfund removal actions have involved engineered wetlands and phytoremediation to treat surface water and groundwater contaminated with high concentrations of carbon tetrachloride due to past fumigation practices at a nearby grain storage facility. The wetlands serve as a remediation polishing step and enhance local wildlife habitat while moderating periodically heavy stormwater runoff.

Figure 3. 12-foot-wide drop structure controlled by a 5-foot-wide stop-log system at the Murdock Groundwater Plume site.

Design of the wetlands included climate change adaptation measures aimed to withstand a 100-year flood event rather than the 25-year event typically specified for constructed wetlands. Associated features of the wetland include a lengthy, meandering pond basin with a plunge pool (trickle basin) as well as a low-flow stream channel to detain stormwater and prevent it from damaging downstream areas. The pond was sized to typically hold less than 3 acre-feet of water; its basin provides a normal pool elevation of 1,210 feet above mean sea level and capability to handle a flood pool elevation of 1,214 feet, the predicted level resulting from a 100-year storm event.

Pool water elevations between 1,208 and 1,211 are managed through an outlet structure constructed of concrete (Figure 3) to handle minor flooding likely to occur in a 10-year period. The structure includes a series of adjustable stop logs made of timber and equipped with a tamper-proof locking system. These design criteria also minimize the likelihood of onsite stormwater to negatively impact drainage tile at adjoining agricultural properties.

Figure 4. Wetland pond with protective buffer strip at the Murdock Groundwater Plume site.

Data collection and integration prior to construction focused on delineating contours of the groundwater and surface water elevations, generating profiles of the onsite stream at the anticipated wetland inlet and outlet, and identifying trees to be protected during construction. The site grading plan included BMPs aimed at mirroring the site's natural conditions while maximizing resilience to storm-related hazards. Post-construction grading was minimized by following existing contours and keeping the anticipated typical depth of the plunge pool relatively shallow. Also, a 25-foot buffer strip (Figure 4) was established along the perimeter of the anticipated wetland acreage to assure no offsite grading occurred during construction and to provide long-term protection against erosion due to high wind or stormwater. The buffer strip was seeded with native flood- and drought-tolerant grasses expected to naturally volunteer; the necessary seed mixes were obtained from a local producer operating less than two miles from the site.

The site's stomwater management plan includes an earthen berm and auxiliary spillway that can accommodate moderate storm events. In addition, a site access road was installed along a corridor least likely to be affected by stormwater, which was downstream of drainage tile around the wetland outlets but upstream of the wetland confluence with the tributary. These points of the road are supported by twin culverts predicted to withstand up to a 25-year storm event.

Figure 5. Returning beaver population and habitat at the Groundwater Plume site wetlands.

The plunge pool at the downstream end of the site is lined with native rock that increases volatilization of any remaining carbon tetrachloride during typical stream flows and dissipates flow energy in the case of catastrophic failure of surface water controls. Other techniques to enhance volatilization of the site's volatile organic compounds include an upstream groundwater extraction and spray-treatment system, which allows for beneficial use of the extracted water. Groundwater extracted from a single well is sprayed via a linear-travel irrigation unit onto adjacent municipal property where it irrigates recreational fields. From 2005 start-up through 2012, the spray-irrigation system discharged a cumulative total exceeding 1.2 million gallons of water at a flow ranging from 30 to 35 gallons per minute. Since 2013, the irrigation need has decreased but the well and spray system have remained in operational condition to address any onsite or offsite needs in the future.

The perimeter of the site is lined with shrubs requiring little maintenance, rather than engineered or wood fencing. Ongoing monitoring indicates a thriving wetland system and successful creation of habitat for native wildlife such as beavers, muskrats, and turtles (Figure 5).

Materials, Waste and Ecosystems: Integrating Materials and Waste Management Plans with Ecosystem Protection

Contributed by Ed Hathaway, U.S. EPA Region 1; Shelby Johnston, U.S. EPA Region 4; Wallace Robertson, Air Force Civil Engineer Center/CZOW, Barksdale IST

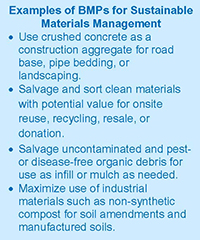

Biobased and recovered materials can effectively be integrated into site waste reduction efforts that decrease the environmental footprint of a cleanup. Relevant best management practices (BMPs) often involve using industrial byproducts for remediation purposes and salvaging onsite waste for beneficial use on- or offsite. The U.S. Environmental Protection Agency (EPA) recently completed full or partial cleanup at three sites where biobased and recovered materials were integrated into the remediation strategy while also helping to restore natural ecosystems and associated services: the Sanford Gasification Plant Superfund alternative site in Seminole County, Florida; the Barksdale Air Force Base (AFB) in Bossier City, Louisiana; and the Elizabeth Mine located in South Stratford, Vermont.

The Sanford Gasification Plant manufactured water gas and carbureted water gas from the 1880s until 1951. An incinerator also operated onsite for over 20 years. Plant processes generated tar and condensate, which were stored onsite in gas holder tanks that frequently leaked, contaminating site soil, groundwater, and sediments in the nearby Cloud Branch Creek and Lake Monroe delta via an intermittently flowing tributary. Investigations in the 1990s and early 2000s indicated the presence of polycyclic aromatic hydrocarbons, metals and total recoverable petroleum hydrocarbons in soil, groundwater and sediment. In addition, tar-saturated soil and sediment, as well as black-stained sediment with a strong naphthalene odor, were observed onsite.

Figure 1. A stormwater retention pond at the Sanford site for mitigating soil erosion.

Cleanup was conducted from 2009 to 2012 under EPA oversight and included removal of the upper 2 feet of contaminated soil (total of 26,934 tons); solidification and stabilization of contaminated soil from 2 to 30 feet below ground surface (total of 143,531 cubic yards) using granulated blast furnace slag; removal of 11,003 cubic yards of Cloud Branch Creek sediment to a minimum depth of 2 feet and restoration through installation of a culvert and backfill; and installation of a well network for monitoring natural attenuation of groundwater after soil cleanup activities are completed. Soil removed from contaminated areas was screened, and clean soil was reused onsite, avoiding importation of 1,600 cubic yards of non-native soil for site restoration. A stormwater retention pond (Figure 1) was built to limit runoff and soil erosion along the restored area. Restoration of Cloud Branch Creek included placement of riprap made from recycled concrete to prevent erosion of the streambanks.

Additional material recovery activities at the site involved chipping, mulching, and sending to local landscape companies about 5,000 cubic yards (800 tons) of trees and stumps that were removed for heavy equipment operation, and reusing 3.7 million gallons of water obtained from dewatering operations in the soil stabilization process. Groundwater at the site will be treated by monitored natural attenuation, which is expected to achieve cleanup criteria in 2035.

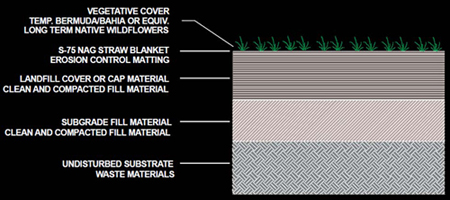

At Barksdale AFB, biobased and recycled onsite materials were incorporated into a cover upgrade and revegetation effort at three landfills: LF002, LF003, and LF004. The covers at LF002 and LF003 had deteriorated such that groundwater recharge was occurring from accumulated stormwater runoff in low topographic areas, while the LF004 cover had been damaged by vehicle traffic during a brief period of concrete recycling operations conducted nearby.

Figure 2. Cross section of the landfill cover installed at LF-03 and 04 at Barksdale AFB.

Remedial activities at all three landfills included constructing 18-24 inch covers to prevent water infiltration into the buried waste, grading to promote runoff and natural drainage patterns, and installation of a vegetative cover to protect the cap and minimize sedimentation in the adjacent Flat River. At LF003, uncontaminated spoil from previous dredging operations was used as the cover material. Recycled fill, such as previously dredged materials from the Flat River, was reused as subgrade fill for the caps at all three landfills, as well as for topsoil at LF003 and LF004 (Figure 2), which avoided importation of 110,000 cubic yards of material. In addition, crushed concrete was recycled as base fill for access roads at all three landfills, as riprap at LF003 and LF0044 to prevent stream bank erosion, and for a wetland buffer at LF004, which avoided importation of 2,000 tons of concrete.

Figure 3. Black-eyed-susans planted at the Barksdale AFB.

Fast germinating grass species were planted immediately at LF003 and 004 as a BMP to minimize landfill cap erosion during the fall rainy season. Once the cover was established, wildflowers were seeded as a BMP to protect ecosystems and associated services by providing a climate-stress and disease resistant cover that also served as a food source for local wildlife. Native wildflowers, including Rudbeckia hirta (black-eyed-susan, Figure 3), Gaillardia pulchella (Indian blanketflower), Echinacea purpurea (purple coneflower), and Papaver rhoeas (shirley poppies), were selected due to their drought-resistant nature, to reduce mowing frequency, restore nutrient cycles, promote seed dispersal, and restore habitat for native wildlife, including pollinator species. Additional wildflower seeding is planned for the near future. An additional BMP implemented at LF003 during the cover replacement included retaining an existing natural levee that served as a wildlife corridor. Keeping the levee also minimized disturbance to the riparian zone and added a layer of protection against erosion and sedimentation. Ecosystem service protection activities at LF003 also included development of hiking trails for the public. The trails were lined with wood mulch (770 cubic yards) derived from selectively cut trees on the AFB, rather than importing mulch from offsite sources. More information about greener cleanup BMPs and associated footprint reductions can be found in the Barksdale Air Force Base green remediation profile.

Figure 4. Organic-rich topsoil for the 45-acre cap at Elizabeth Mine Superfund Site was manufactured onsite.

At the 250-acre Elizabeth Mine Superfund Site, biobased materials, land conservation, and ecosystem services protection BMPs were integrated into cleanup of the tailing piles and waste rock as part of a non time-critical removal action (NTCRA) conducted from 2011 to 2014. The site is a former copper mine that operated from the early 1800s until closure in 1958. Cleanup goals for the site were to restore water quality of Copperas Brook, the West Branch of the Ompompanoosuc River, and water resources further downstream that have been negatively impacted by acid rock drainage from waste rock and tailing piles. The entire length of Copperas Brook and several miles of the West Branch of the Ompompanoosuc River failed to meet Vermont Water Quality Standards prior to the cleanup action.

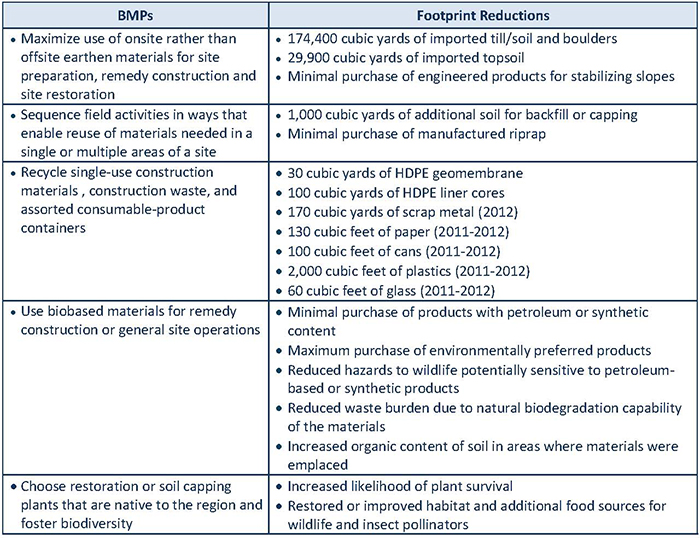

Cleanup as part of the NTCRA consisted of excavation and consolidation of over 500,0000 cubic yards of waste rock, installation of a 45-acre cap over the tailings impoundment and consolidated waste rock (completed in 2012), and channel modification in Copperas Brook as a BMP for erosion control. The nearly 174,400 cubic yards of earthen fill (including 165,000 cubic yards of till/soil and 9,400 cubic yards of boulders) needed for site preparation, cap construction and site restoration were obtained onsite. An additional BMP included creating the approximately 29,900 cubic yards of topsoil needed for the cap using onsite soil, woodchips generated from clearing activities, and manure from local farms, eliminating the hauling and disturbance associated with importing topsoil from an offsite source (Figure 4). In addition, riprap initially used to stabilize an area of waste rock excavation was removed and reused onsite. The area of riprap removal was subsequently stabilized with native vegetation. Shredded stump grindings were salvaged and used to stabilize steep slopes.

Figure 5. Slope stabilization and erosion control at the Elizabeth Mine Superfund Site was achieved using a compost blanket combined with tubular sediment control devices.

Ecosystem services protection measures undertaken at the site during the NTCRA cleanup efforts included stabilizing topsoil and revegetating the cap, and constructing wetlands. Biodegradable, wood fiber-based material (Flexterra®) was used to stabilize the topsoil surface throughout the entire 45-acre cap and areas of steep slopes in the borrow source areas to prevent erosion and promote vegetative growth. Tubular sediment control devices and blown compost blankets were also used to prevent erosion and promote vegetative growth outside the cap (Figure 5). These materials allowed the area to naturally revegetate and minimized hazards to wildlife synthetic mesh blankets can pose. Weed-free pelletized mulch (EZ Mulch®) made from recycled newsprint and corn fiber was used to supplement seed establishment, where needed. A variety of seed mixes used for revegetation contained native plant species that could thrive in the exposed cap, wet meadow and forest areas, provide erosion control, create habitat and food sources for insects, birds, and other wildlife, and offer grass and wildflower diversity. By the end of 2013, more than 10 acres of wetland were created with a diverse selection of native trees, shrubs, emergent plugs, tublings, and live stakes (totaling approximately 1,500 plants) planted to create a native habitat for wetland and pollinator species. In addition, ecological habitat for the region's endangered bats was preserved by installing bat grates at the mine openings before beginning construction work.

Implementation of these and other greener cleanup BMPs, and resulting footprint reductions at Elizabeth Mine merited the project's receipt of a 2014 Green Dream Team Award under the U.S. Army Corps of Engineers Sustainability Award Program (Figure 6).

Figure 6. Examples of BMPs used at the Elizabeth Mine Superfund Site to reduce material, waste, land, and ecosystem contributions to the project's environmental footprint, and associated quantitative or qualitative reductions to the footprint. For more information, visit the Elizabeth Mine green remediation profile.

RESOURCES

EPA Website: Greener Cleanups

EPA's Greener Cleanups website supports EPA's Principles for Greener Cleanups, which provide a foundation for improving the cleanup decision-making process in a way that ensures protection of human health and the environment while minimizing the environmental footprint of cleanup activities. The principles may be applied to cleanups under any regulatory program, including those involving Superfund, Resource Conservation and Recovery Act, Toxic Substances Control Act, federal facility, brownfield, state and voluntary actions. In addition to the principles, this website provides basic information about greener cleanups, describes the Agency's related Superfund Green Remediation Strategy, and provides links to decision tools.

CLU-IN Website: Green Remediation Focus

The Green Remediation Focus area of CLU-IN provides news about strategies to minimize the environmental footprint of activities involved in contaminated site cleanup. This website also holds key documents such as EPA's series of BMP fact sheets, project profiles and links to other information such as greener policies tailored by EPA regions and related state initiatives. Technical materials accessible through Green Remediation Focus address topics such as the application of renewable energy at sites undergoing cleanup and the integration of BMPs into site investigation and remedy design, construction or operation.

Industry Standard: ASTM Standard Guide for Greener Cleanups

EPA and some states encourage use of the ASTM Standard Guide for Greener Cleanups (E2893-13), an industry consensus standard that provides a systematic protocol for identifying, prioritizing, selecting, implementing and reporting on the use of BMPs to reduce the environmental footprint of a cleanup project. The standard also provides uniform expectations for projects applying to different, or in some cases multiple, cleanup programs administered by federal, state or local authorities in the U.S. Release of an updated standard is anticipated in early 2016.

Updated Fact Sheet: Green Remediation Best Management Practices: An Overview

As one in a series of BMP fact sheets, Green Remediation Best Management Practices: An Overview summarizes the benefits of greener cleanups and describes where and when to use greener cleanup BMPs. It also provides links to the additional (13) BMP fact sheets, which address specific topics such as pump-and-treat systems or other common remediation technologies, site types such as mining sites, or particular core elements such as materials management and waste reduction. [this abstract is subject to revision pending OSRTI release of the updated fact sheet]

Project Update: Greener Cleanups Bulletin: Application of the ASTM Standard Guide for Greener Cleanups at the North Ridge Estates Superfund Site

EPA has launched a "greener cleanup bulletin" series to disseminate news about environmental footprint reductions at specific sites undergoing cleanup. As the first in the series, Application of the ASTM Standard Guide for Greener Cleanups at the North Ridge Estates Superfund Site summarizes EPA's application of the ASTM Standard Guide for Greener Cleanups to plan remediation at operable unit 1 of the North Ridge Estates site near Klamath Falls, Oregon. Use of the standard helped project staff screen, prioritize and select BMPs for incorporation in remedy design and construction contracts. The remedy involves extensive excavation and soil cap construction.

Updated Planning Tool: Greener Cleanups Contracting and Administration Toolkit

EPA, other federal agencies and some states are adding greener cleanup considerations to formal agreements such as remediation service contracts, grant terms or conditions, and cleanup approval plans. For example, EPA Regions 1 and 10 now recommend or require adherence to the ASTM Standard Guide for Greener Cleanups as a condition of approving plans for cleaning up sites contaminated by polychlorinated biphenyls. EPA's Greener Cleanups Contracting and Administration Toolkit outlines contracting language and describes similar provisions in administrative documents such as interagency agreements or state guidance.

New Analytical Tool: SEFA Tutorial

EPA's Excel-based Spreadsheets for Environmental Footprint Analysis (SEFA) may be used to prepare an environmental footprint analysis as described in the Methodology for Understanding and Reducing a Project's Environmental Footprint. A SEFA tutorial is now available to help new users learn more about the SEFA input process and understand the SEFA outputs. Footprint analyses can identify and document contributions to the environmental footprint of a cleanup, thereby directing stakeholders' attention to opportunities for reducing the footprint.

Supporting Decision Tools: Updated Models, Calculators and Maps

Industrial Waste Management Evaluation Model (IWEM). IWEM is a screening-level groundwater model that simulates contaminant fate and transport. The latest version of the IWEM software (V3.1), released in August 2015, includes additional tools to evaluate beneficial use of industrial materials, including byproducts such as silica-based spent sands generated by iron, steel and aluminum foundries. IWEM now contains six modules intended to help determine the most appropriate liner design for waste management units (landfills, land application units, surface impoundments and waste piles) and to help evaluate appropriateness of reusing an industrial material in roadway construction and structural fill.

National Stormwater Calculator (SWC). The SWC is a desktop application that estimates the annual amount of rainwater and frequency of runoff from a site anywhere in the U.S. This tool accesses several national databases providing soil, topography, rainfall and evaporation information. SWC input supplied by the user includes information about the site's land cover and the preferred types of low-impact development controls involving green infrastructure practices such as harvesting rain water and constructing infiltration basins.

RE-Powering Mapper. As a Google Earth-based tool, RE-Powering Mapper enables users to view maps and supporting information concerning renewable energy potential on contaminated lands, landfills and mine sites. As of August 2015, EPA had screened the solar, wind, biomass and geothermal energy potential at more than 80,000 sites. The latest round of screening, which uses criteria developed in collaboration with the U.S. Department of Energy's National Renewable Energy Laboratory, includes information provided by state agencies in California, Hawaii, Illinois, Massachusetts, New Jersey, New York, Oregon, Pennsylvania, Texas, Virginia and West Virginia.

Waste Reduction Model (WARM). WARM is an online worksheet designed to help solid waste planners and organizations track and voluntarily report GHG emissions reductions and energy savings achievable through different waste management practices. It also allows users to compare baseline and alternative scenarios for factors such as the tonnage of waste that is recycled, landfilled or combusted and the distance over which waste is transported for offsite disposal. The most recent update (Version 13, 2015) of WARM addresses nearly 50 waste materials such as high-density polyethylene, concrete and fly ash.

Contact Us:

Suggestions for articles in upcoming issues of Technology News and Trends may be submitted to

Linda Fiedler via email at fiedler.linda@epa.gov.

Past Issues:

Past issues of the newsletter are available at http://www.clu-in.org/products/newsltrs/tnandt/.

Archives | Subscribe | Change Your Address | Unsubscribe