Green Remediation Focus

Busy Bee's Laundry

Rolla, Missouri

MO Voluntary Cleanup

Cleanup Objectives: Remediate source-area groundwater contaminated by volatile organic compounds (VOCs) released from dry cleaning operations conducted in the 1960s and 1985-1991, and address VOCs detected in an adjacent municipal park reservoir and off-site wells. Although earlier introduction of bioremediation reagents showed evidence of success in reducing total VOC concentrations in source-area groundwater, the Missouri Department of Natural Resources (MO DNR) determined in 2009 that additional efforts involving pump-and-treat (P&T) technology were needed to accelerate site cleanup.

Green Remediation Strategy: Rely exclusively on renewable energy sources for power needed to operate a P&T system, maximize re-use of the site's existing infrastructure, and minimize negative effects of cleanup activities on the adjacent park and reservoir

- Install an onsite photovoltaic (PV) array to convert solar energy to direct current electricity needed for operating one 400-watt surface-mounted piston pump

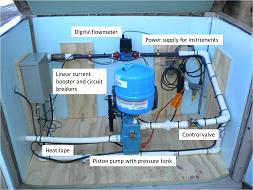

- Use a linear current booster instead of batteries or other energy storage devices to maximize energy flow and reduce cleanup costs

- Evaluate utility of solar insolation data collected on the site and at a nearby Missouri University of Science & Technology (MO S&T) project to predict the pumping rate

- Rely on intermittent pumping to match variable amounts of direct current supplied by the PV system while potentially increasing the rate of contaminant mass removal; design called for the groundwater extraction system to automatically start/stop each day, based on the availability of solar energy

- Treat the extracted groundwater with reactivated granular activated carbon (GAC) and discharge treated water to the publically owned treatment works

- Minimize the need to install new extraction or monitoring wells and to construct a treatment shed, through maximum use of the site's existing infrastructure

- Use the State's voluntary cleanup program and Missouri Drycleaning Environmental Response Trust (DERT) Fund to leverage cooperative funding from MO S&T, cleanup and renewable-energy expertise of local environmental professionals, and interest from the property owner

- Minimize disruption to current use of the property for a commercial laundry facility

- Engage the local community through a media campaign and precollege outreach programs to assure community interest in the project as an opportunity for education, improved environmental stewardship, additional security for the cleanup and renewable energy systems, and positive perceptions from visitors at the adjacent park

Results:

- Selected a 560-watt passive tracking PV system, based on: (1) anticipated energy demand of the groundwater pumping system, which was rated at 9.1 gallons per minute (at 140 feet of total dynamic head), and (2) a renewable energy assessment conducted through use of the National Renewable Energy Laboratory's PVWatts™ model, which indicated a potential pumping rate of 55-89 hours per month (depending on seasonal solar variation)

- Installed the PV system over three days in December 2010 and January 2011; MO S&T faculty and graduate students completed the installation with assistance from the property owner's cleanup contractor

- Identified one existing onsite well to use for groundwater extraction, 10 existing (four onsite and six offsite) wells to use for groundwater monitoring, and a portion of the existing onsite building to house the GAC materials and equipment

- Began operating the treatment system in late January 2011; since start-up, the system has been briefly suspended twice to avoid freeze damage to the pump due to unusually cold weather

- Fabricated and installed a timer that temporarily suspends pumping when the rate of groundwater flow drops below a pre-determined level, to allow intermittent well recovery

- Extracted more than 1,800 gallon of groundwater during the first four weeks of operation, at an average rate of 100-160 gallons per day, for ex situ treatment

- Identified a good correlation between pumping periods and the off-site solar insolation measurements, which suggests the PV system is supplying an energy quantity within the range predicted in the project design phase

- Gained project savings by avoiding the need to install additional wells or to construct and operate a heated treatment shed

- Temporarily collecting the extracted water in onsite storage tanks for periodic transfer to the existing vadose-zone bioapplication trenches, due to discovery of residual bioremediation reagent in the groundwater; GAC treatment is anticipated to begin in 2011 when tetrachloroethylene concentrations in groundwater begin to increase (indicating a declining rate of bioremediation)

- Tracking the rates of energy production and groundwater extraction (which currently serves as a means to accelerate circulation of carbon donor in groundwater) and collecting groundwater samples for weekly analysis by an offsite laboratory, to evaluate efficacy of the transitioning treatment technologies

Property End Use: Ongoing commercial laundry operations

Point of Contact: Vicky Kugler, MO DNR; Dave Drake, U.S. EPA Region 7; and Curt Elmore, MO S&T